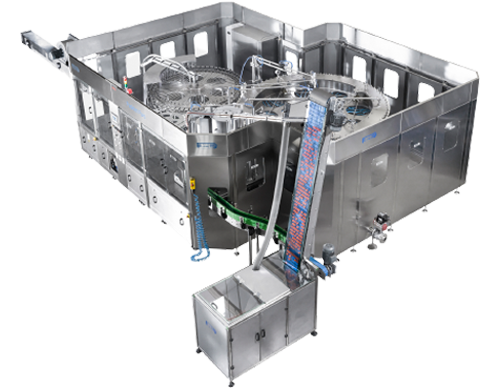

The machine is used to identify and sort various metals in bulk or packaged products.

Defective products can be removed or the system stopped by audible and visual alarms (optical and audio)

In bulk products, metals are sorted by compressed air ejectors, and in packaged products, metals are sorted by human workers or mechanical ejectors.

Output: 2 – 5 tons per hour

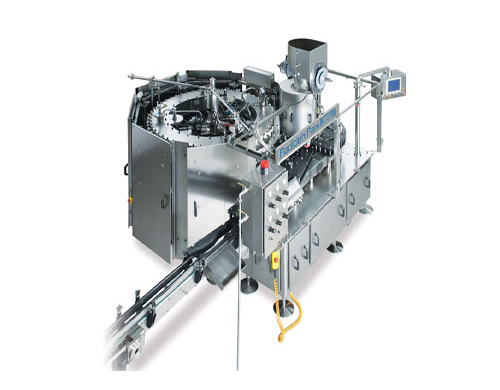

Metal detectors are an essential part of packaging machines used in the food industry to detect and remove metal contaminants from food. These contaminants may enter food during processing, packaging or distribution and may cause harm to consumers if not detected and removed. A metal detector

is an instrument that detects the presence of metal in the vicinity. Metal detectors can be used to find metal objects above ground, underground and underwater. A metal detector consists of a control box, an adjustable shaft and a pickup coil of variable shape.

Food metal detectors are used to identify and remove metal contaminants in the food processing industry. The main purpose of metal detectors is to protect consumers from metal particles that may enter the food production line during the production process.

+7929688-88-14

+7929688-88-14

Chinese

Chinese

Persian

Persian

English

English

Russian

Russian

+7929688-88-14

+7929688-88-14

包装机

包装机