Printing Machine

Printing machines play a pivotal role in the reproduction of text and images, revolutionizing the way information is disseminated. These machines have evolved significantly over time, from traditional methods like letterpress to modern digital printing technologies.

In the early days, letterpress printing dominated the industry. This method involved arranging movable type and pressing inked characters onto paper. It was time-consuming and required skilled operators. With the advent of offset printing in the 20th century, a more efficient process emerged. Offset printing employs a rubber blanket to transfer ink from a plate to paper, enabling faster and higher-volume production.

Digital printing, a more recent innovation, has further transformed the landscape. This method eliminates the need for printing plates, allowing for shorter print runs and personalized content. Inkjet and laser printers are common digital printing technologies, with widespread use in homes and offices. These machines are capable of producing high-quality prints at a rapid pace.

3D printing, a revolutionary development, adds a new dimension to the concept of printing. Unlike traditional printing, 3D printing creates three-dimensional objects layer by layer from digital models. This technology has applications across various industries, from manufacturing prototypes to creating customized products.

The environmental impact of printing machines has also been a focus of development. Eco-friendly practices, such as using soy-based inks and recycled paper, contribute to sustainability in the printing industry.

As technology continues to advance, so too will printing machines. From improved efficiency and speed to enhanced environmental sustainability, the evolution of printing technology reflects a constant drive for innovation in the reproduction of information and images.

Printing machines find applications across diverse industries and settings:

1. Publishing Industry: Printing machines are extensively used in book and magazine production, allowing for mass reproduction of reading materials.

2. Advertising and Marketing: The creation of promotional materials, such as brochures, flyers, and banners, relies heavily on printing machines to produce high-quality visuals.

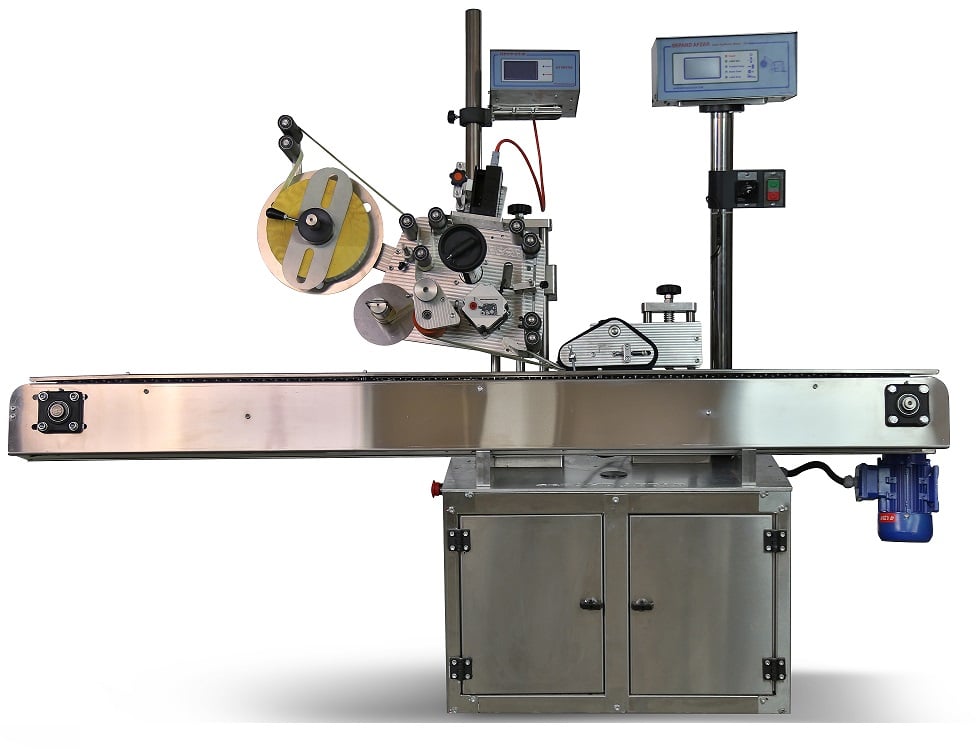

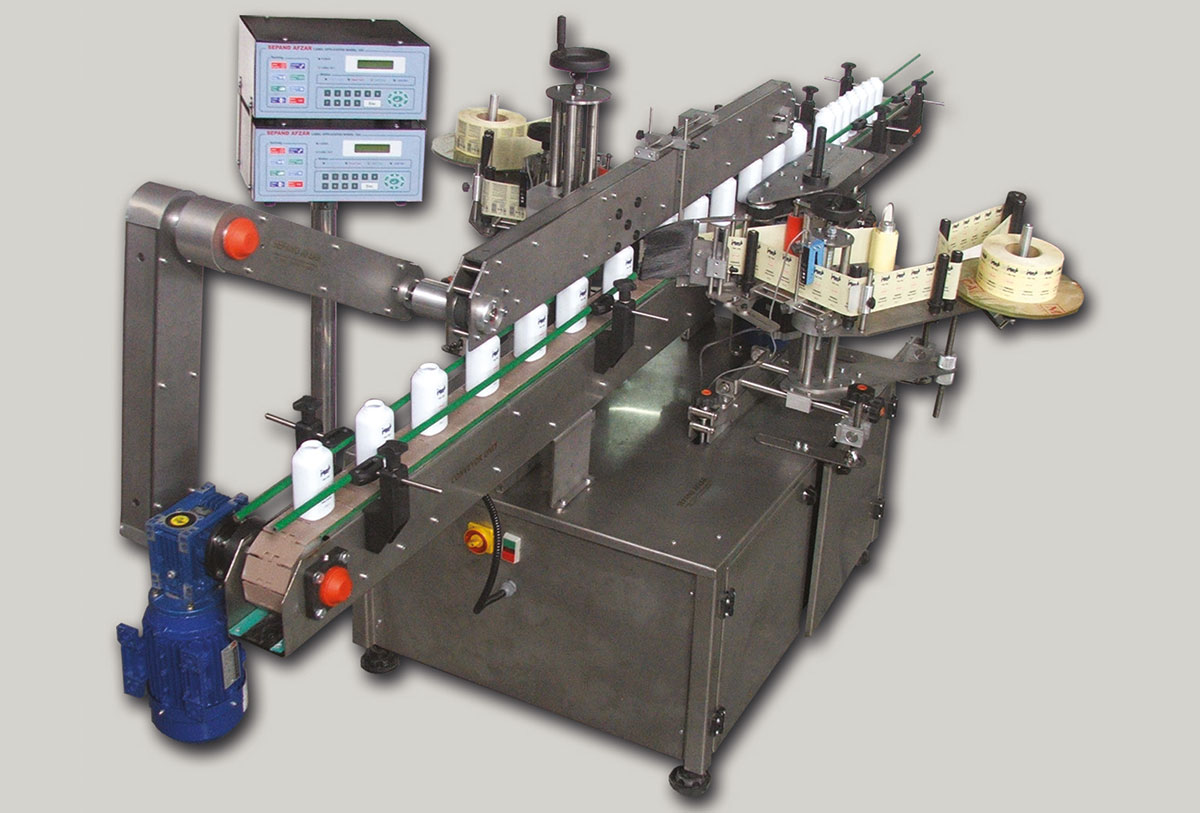

3. Packaging: Printing machines contribute to the printing of labels, packaging materials, and product information, ensuring branding and compliance with regulations.

4. Textile Industry: Textile printing machines are employed to add designs and patterns to fabrics and garments, contributing to the fashion and textile manufacturing sectors.

5. Education Sector: Schools and universities use printing machines for producing textbooks, educational materials, and various documents required for administrative purposes.

6. Corporate Offices: Printing machines are commonly found in offices for tasks like printing reports, presentations, and other essential documents.

7. Manufacturing and Prototyping: 3D printing machines are utilized in manufacturing for rapid prototyping and creating complex components with precision.

8. Healthcare: In the healthcare sector, printing machines are employed for producing medical labels, packaging, and even for 3D printing of prosthetics and implants.

9. Art and Design: Printing machines are crucial in the art and design fields, allowing artists to reproduce their work, create limited edition prints, and experiment with various printmaking techniques.

10. Architectural and Engineering: Large-format printers are used in these fields for producing detailed blueprints, schematics, and architectural drawings.

11. Photography: Professional photo printers are used in photography studios for creating high-quality prints of photographs.

12. Government and Legal: Printing machines are used in government offices for producing official documents, reports, and legal paperwork.

The ubiquity of printing machines spans a wide range of sectors, contributing to the efficiency, communication, and aesthetic appeal of various industries and daily life.

There are several types of printing machines, each with its own specific technology and applications. Here are some of the main types:

1. Offset Printing: This traditional method uses printing plates and a rubber blanket to transfer ink to paper. It is widely used for high-volume commercial printing.

2. Digital Printing: Utilizes digital technology to reproduce images directly from digital files without the need for printing plates. Inkjet and laser printers are common examples, suitable for short print runs and personalized content.

3. Flexographic Printing: Common in packaging and label printing, flexography uses flexible relief plates and fast-drying inks for high-speed, efficient printing on various materials.

4. Screen Printing: Involves pressing ink through a mesh screen onto a substrate. It's versatile and used for printing on textiles, signage, and promotional products.

5. Gravure Printing: Utilizes engraved cylinders to transfer ink onto the printing surface. It's often employed in high-quality, long-run printing, such as magazines and packaging.

6. Letterpress Printing: An older technique where raised surfaces with ink are pressed onto paper. It's less common today but still used for specialty printing.

7. 3D Printing: Unlike traditional printing, 3D printing creates three-dimensional objects layer by layer from digital models. It has applications in various industries, including manufacturing and healthcare.

8. Inkjet Printing: Commonly used in homes and offices, inkjet printers spray tiny droplets of ink onto paper to create images and text.

9. Laser Printing: Utilizes a laser beam to create an electrostatic image on a drum, which attracts toner particles and transfers them to paper. It's commonly used for high-speed and high-quality document printing.

10. Dye-Sublimation Printing: A heat transfer process where solid dye is converted into a gas and permeates the surface of the printing substrate. It's often used for printing on fabrics and rigid materials.

These are just a few examples, and within each category, there can be variations and specialized applications. The choice of printing machine depends on factors such as the intended use, volume of production, and the type of materials being printed.

Printing machines play a crucial role in the exporting process across various industries. Here are several ways in which they contribute:

1. Packaging for Export: Printing machines are extensively used to create labels, packaging materials, and product information that comply with international standards. Well-designed and informative packaging is essential for global trade, ensuring products are properly identified and meet regulatory requirements.

2. Documentation Printing: The export process involves a plethora of documents such as invoices, shipping labels, and certificates of origin. Printing machines are indispensable for producing these documents accurately and efficiently.

3. Branding and Marketing Collateral: Exported products often carry the brand image of the company. Printing machines are crucial for producing marketing materials like brochures, catalogs, and promotional items that contribute to branding efforts in international markets.

4. Customs and Compliance Labels: Printing machines are used to create labels that comply with customs regulations and convey necessary information about the contents, handling instructions, and other regulatory requirements.

5. Textile and Apparel Printing: In the fashion and textile industry, printing machines are utilized for printing designs on fabrics and garments that are destined for export. This adds aesthetic appeal and branding to the products.

6. Manufacturing and Prototyping: 3D printing machines, with their ability to create prototypes and intricate components, facilitate the manufacturing process. This is particularly beneficial for companies involved in exporting specialized products or components.

7. Production of Export-related Materials: Printing machines are involved in producing various materials related to export, such as export documentation, product manuals, and user guides, which are essential for the smooth functioning of products in international markets.

8. Promotional Materials for Trade Shows: When companies participate in international trade shows and exhibitions to promote their products, printing machines are used to create eye-catching banners, posters, and promotional materials.

9. Communication Materials: Printing machines contribute to the production of business cards, letterheads, and other communication materials that play a role in establishing and maintaining international business relationships.

The role of printing machines in exporting is multifaceted, encompassing everything from compliance and documentation to marketing and branding. Their efficiency and versatility contribute significantly to the success of companies engaged in international trade.

FAQs

What's the work of the printing machine?

Printing machines reproduce text and images on various surfaces, playing a key role in industries like publishing, packaging, and marketing.

How many types of printing machine do we have?

There are several types, including offset, digital, flexographic, screen, gravure, letterpress, 3D, inkjet, laser, and dye-sublimation printing machines.

What is the printing machine called?

The term "printing machine" is a general term. Specific types include offset printers, digital printers, flexographic printers, etc., depending on the printing technology used.

Why is the printing machine important?

Printing machines are crucial for mass production of documents, packaging, and promotional materials, facilitating efficient communication, branding, and information dissemination across various industries.