Sweets

Sweets, also known as candies or confectioneries, are delightful treats loved by people of all ages around the world. These delectable creations come in a wide variety of flavors, textures, and forms, and they have been enjoyed for centuries.

One of the most popular types of sweets is chocolate. Derived from the cacao bean, chocolate is a versatile ingredient that can be transformed into various mouthwatering confections. From smooth and creamy milk chocolate to rich and intense dark chocolate, there is a chocolate treat to suit every preference. Chocolate bars, truffles, bonbons, and chocolate-covered fruits or nuts are just a few examples of the countless chocolate delights available.

Another beloved category of sweets is gummy candies. These chewy, gelatin-based treats come in an array of shapes, sizes, and flavors. Whether it's gummy bears, gummy worms, or gummy fruits, they offer a delightful combination of sweet, fruity taste and a satisfying texture. Gummy candies are often enjoyed as a snack or as a playful addition to desserts.

Hard candies are also widely cherished. These candies are typically made by heating sugar syrup and then allowing it to cool and harden. They come in various flavors, such as fruit, mint, or caramel, and are often enjoyed by slowly savoring them as they dissolve in the mouth. Hard candies can be found in different forms, including lollipops, rock candies, or candy canes.

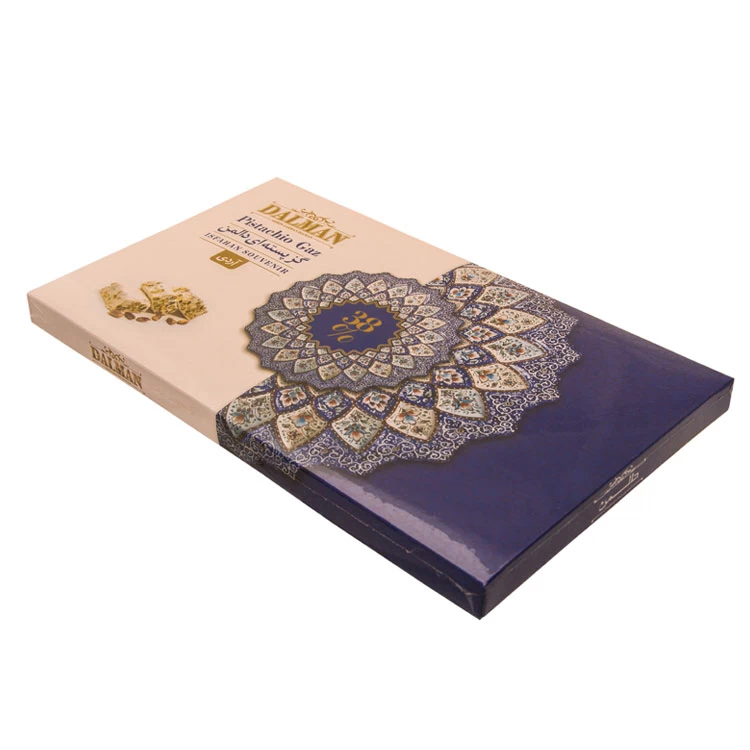

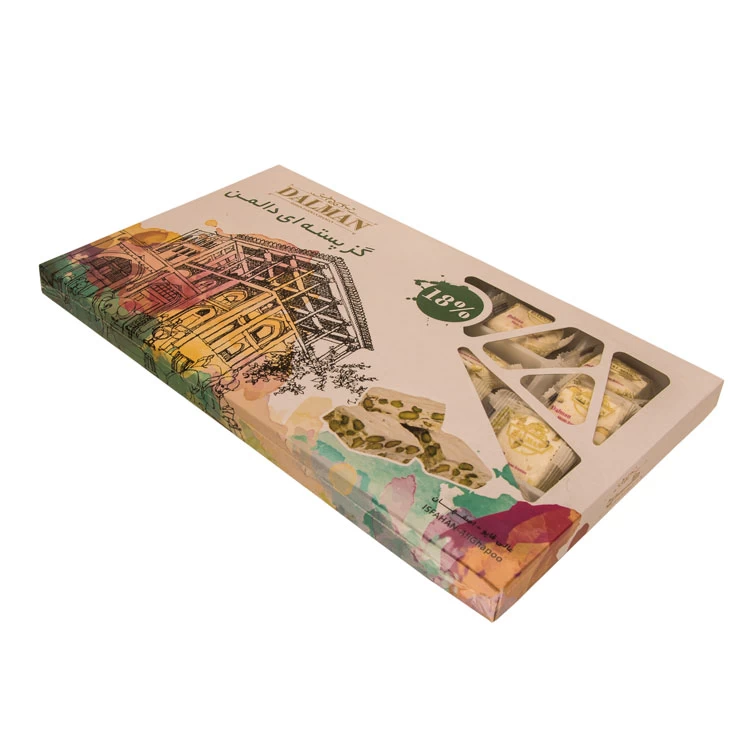

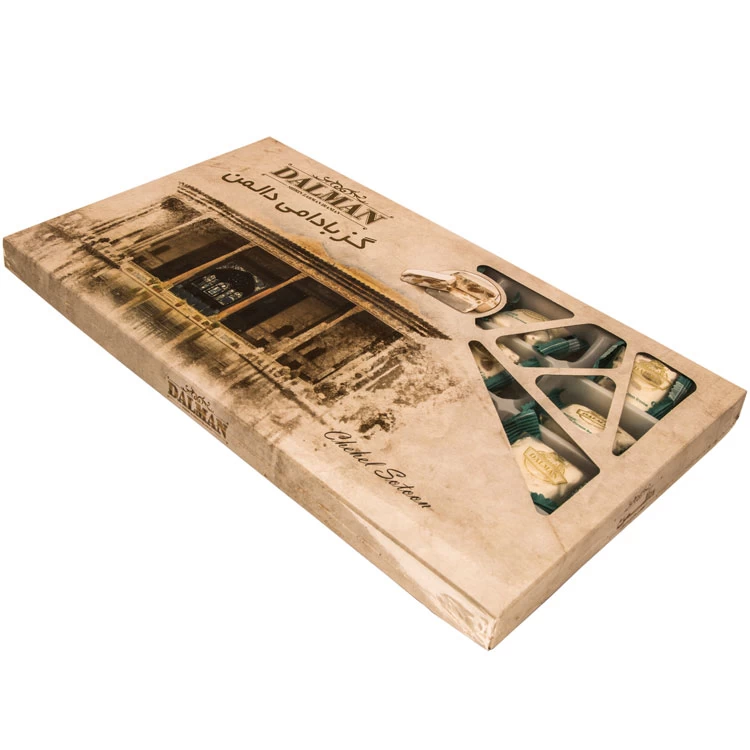

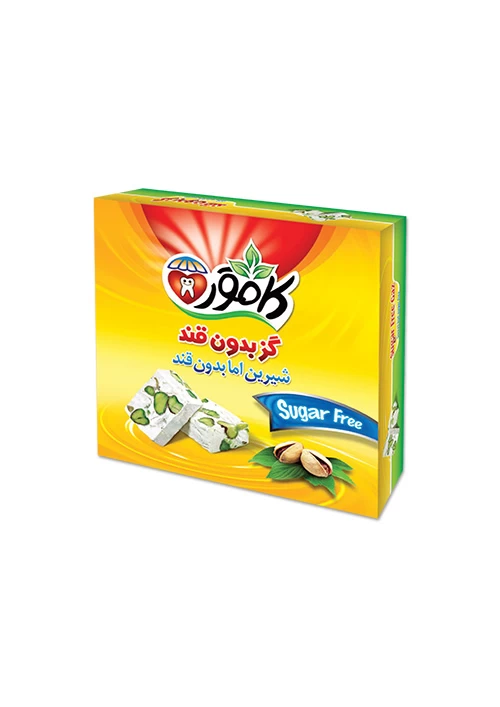

Furthermore, there are a plethora of regional and cultural sweets that have their own unique charm. For instance, in India, you have the colorful and aromatic delights of traditional sweets like barfi, gulab jamun, and jalebi. In the Middle East, you can find the delicate and syrup-soaked pastries like baklava. Each culture has its own traditional sweets that reflect local flavors and culinary traditions.

Sweets are not only enjoyed for their taste but also for the joy and nostalgia they bring. They are often associated with celebrations, holidays, and special occasions. Whether it's Halloween, Christmas, birthdays, or simply a small indulgence to brighten one's day, sweets have a way of adding sweetness to life.

While sweets are undoubtedly delicious, it's important to enjoy them in moderation as part of a balanced diet. Excessive consumption of sugary treats can have negative health effects. However, when enjoyed in moderation, sweets can bring a delightful burst of flavor and a touch of happiness to our lives.

Sweets machinery plays a crucial role in the production and packaging of various confectioneries, ensuring efficiency, consistency, and high-quality output. These machines are designed to handle different stages of the sweets manufacturing process, from mixing and shaping the ingredients to packaging the final products.

Mixing and Cooking: In the initial stages of sweets production, machinery is used for mixing and cooking the ingredients. Large mixers and cookers are employed to blend the necessary components such as sugar, flavorings, colorings, and other ingredients. The mixture is heated and cooked to achieve the desired consistency and texture.

Shaping and Forming: Once the ingredients are mixed, machinery is used to shape and form the sweets. For example, for gummy candies, there are specific machines that pour the cooked mixture into molds, creating various shapes like bears, worms, or fruits. Similarly, for hard candies, molds and forming machines are utilized to shape the hot candy syrup into desired shapes and sizes.

Cooling and Drying: After the sweets are shaped, cooling and drying processes are essential to set and solidify the candies. Cooling tunnels or conveyors with controlled temperature and airflow are used to gradually cool down the candies, allowing them to harden and attain their final texture.

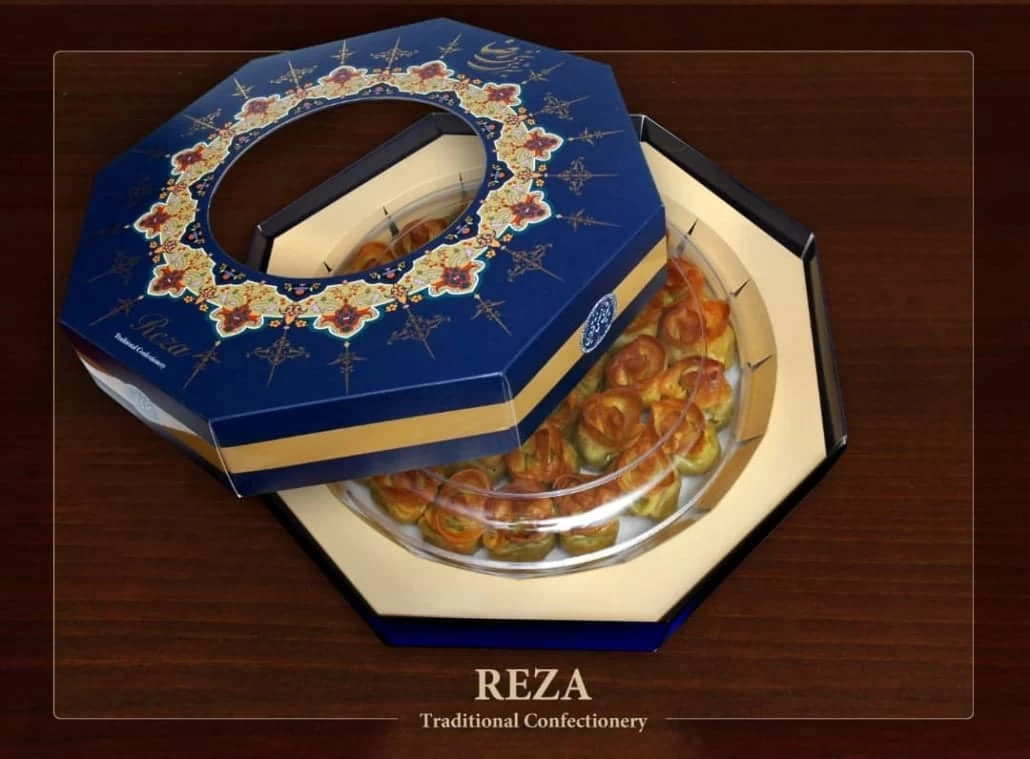

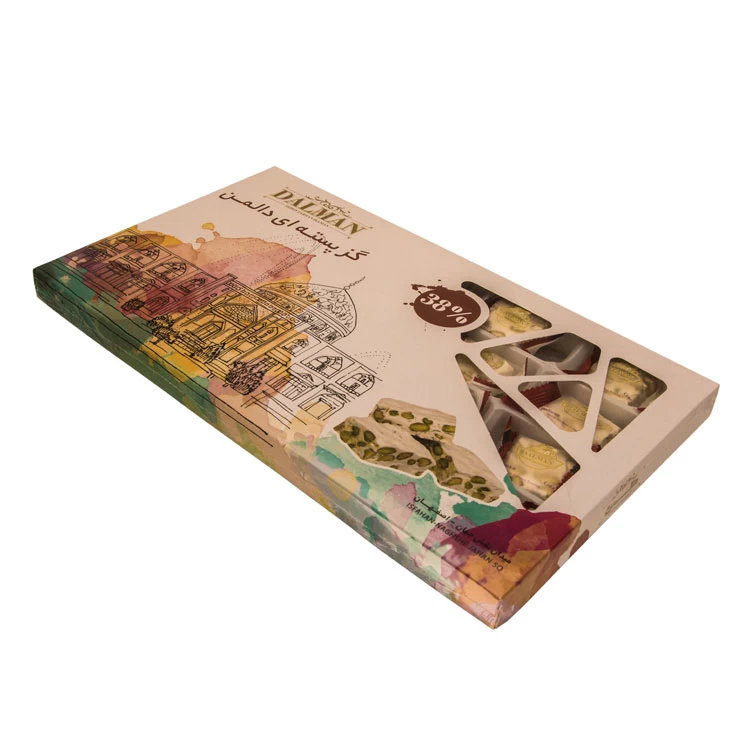

Packaging: Packaging machinery is employed to protect the sweets, maintain freshness, and ensure proper presentation. These machines can handle different packaging formats, such as individual wrappers, pouches, boxes, or jars. They often include automated processes for filling, sealing, labeling, and sometimes even wrapping the sweets.

Exporting sweets involves a complex supply chain that ensures the safe and efficient transportation of confectioneries across borders. Exporters of sweets need to consider various factors such as compliance with international food safety regulations, packaging requirements, and logistical considerations.

To export sweets, manufacturers must ensure that their production facilities meet the necessary quality standards and certifications to guarantee the safety and quality of their products. This may involve adhering to specific manufacturing practices, implementing hygiene protocols, and conducting regular inspections and audits.

Packaging plays a crucial role in exporting sweets, as it needs to be designed to withstand transportation and storage conditions while preserving the freshness and appearance of the products. Proper labeling and compliance with food labeling regulations of the target market are also essential.

Logistics and distribution are key aspects of exporting sweets. Exporters need to coordinate with shipping companies or logistics providers to handle the transportation of sweets to the desired destinations. They must consider factors like transportation modes, temperature control, customs procedures, and documentation requirements.

Additionally, exporters may need to conduct market research and understand the preferences and regulations of the target markets they wish to export to. This includes identifying potential buyers, establishing distribution channels, and navigating import regulations and tariffs.

Overall, the machinery used in sweets production and the export process play vital roles in ensuring the efficiency, quality, and successful distribution of confectioneries to customers around the world.

Sweets are important in a wide range of products, and they play a significant role in various industries. Here are a few examples:

1. Retail Confectionery: Sweets are the primary focus of the confectionery industry. This includes a wide assortment of candies, chocolates, gummies, hard candies, caramels, toffees, and more. These products are consumed as stand-alone treats or incorporated into gift packages, snack assortments, and seasonal offerings.

2. Bakery and Pastry: Sweets are essential ingredients in bakery and pastry items. They are used to enhance the flavor, texture, and visual appeal of cakes, pastries, cookies, muffins, and other baked goods. For instance, sprinkles, frosting, icing, chocolate chips, and various fillings are common sweet elements used in these products.

3. Ice Cream and Frozen Desserts: Sweets are often incorporated into ice cream and frozen desserts to provide added flavor and texture. This can include ingredients like chocolate chips, cookie dough, caramel swirls, fruit syrups, candy bits, and more. Sweets are crucial in creating a diverse range of indulgent frozen treats.

4. Beverages and Flavorings: Sweets are used to add sweetness and flavor to a variety of beverages. This includes syrups for coffee and specialty drinks, flavored powders for milkshakes, hot chocolates, and flavored teas. Sweeteners like sugar, honey, and artificial sweeteners are also used in many beverages.

5. Snack Foods: Sweets are often incorporated into snack foods to provide a sweet and indulgent experience. Examples include snack bars, granola bars, trail mixes, popcorn coatings, and yogurt-covered snacks. These products combine sweet elements with other ingredients to create a balanced and enjoyable snacking experience.

These are just a few examples of the numerous products in which sweets play an important role. Sweets add flavor, sweetness, and enjoyment to a wide variety of food and beverage offerings, catering to the diverse preferences of consumers around the world.

These are just a few examples of the numerous products in which sweets play an important role. Sweets add flavor, sweetness, and enjoyment to a wide variety of food and beverage offerings, catering to the diverse preferences of consumers around the world.

FAQs

What are some popular types of sweets enjoyed worldwide?

Chocolates, gummy candies, hard candies, and traditional regional sweets.

How are sweets produced, and what role does machinery play in their manufacturing process?

Sweets are produced through mixing, shaping, cooling, and packaging processes, with machinery playing a vital role in each step.

What are some cultural and regional variations of sweets around the world?

Barfi, gulab jamun, jalebi (India), baklava (Middle East), and countless others.

What are some considerations and challenges involved in exporting sweets to international markets?

Quality standards, packaging requirements, logistics, and market regulations.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14