Machinery

Machinery refers to mechanical devices or equipment. It plays a crucial role in various industries, automating tasks and improving efficiency.

Machinery encompasses a wide range of mechanical devices, from simple tools to complex industrial equipment. It involves the use of mechanical power to perform tasks, making processes more efficient and often reducing manual labor. Industries like manufacturing, agriculture, and transportation heavily rely on machinery for increased productivity and precision. Advances in technology continue to shape and improve the capabilities of machinery across various sectors.

Machinery comes in various types, including:

1. Simple Machines: Basic tools like levers, pulleys, and inclined planes.

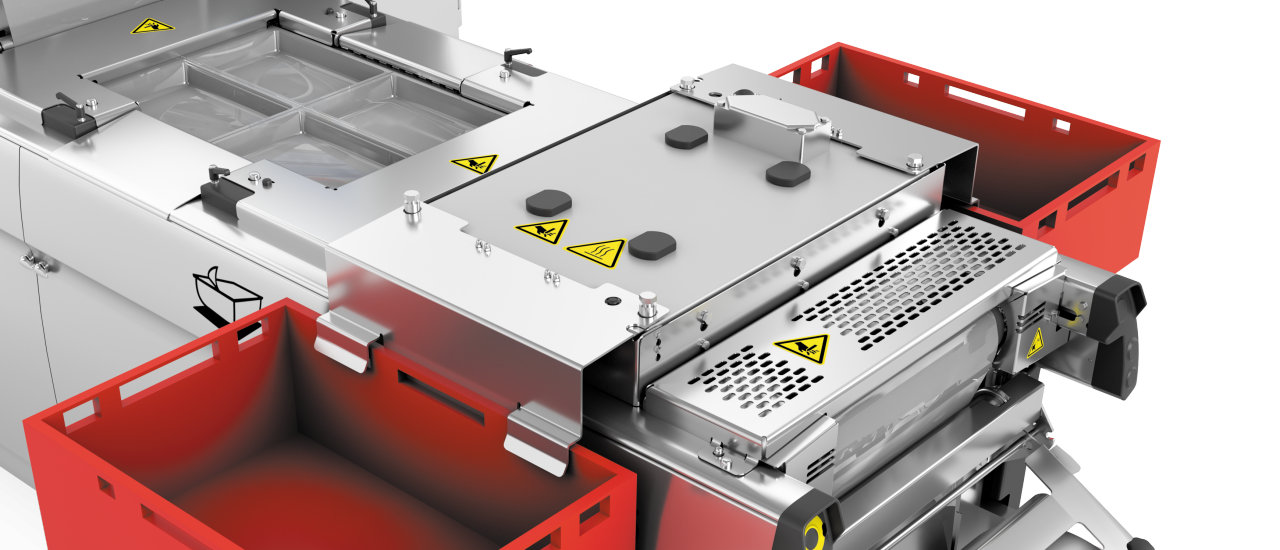

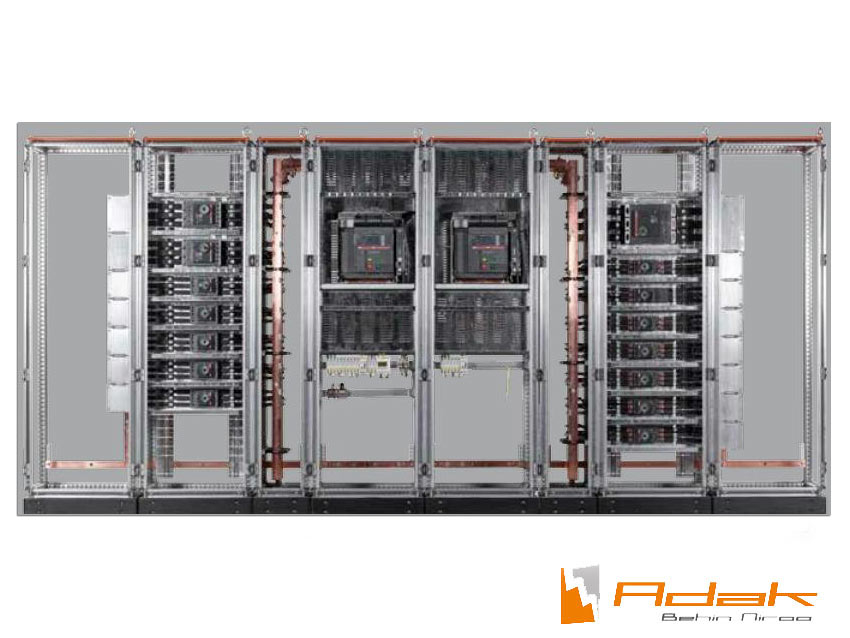

2. Industrial Machines:Complex equipment used in manufacturing and production processes.

3. Construction Machinery: Excavators, bulldozers, and cranes for building and infrastructure.

4. Agricultural Machinery: Tractors, combines, and plows for farming activities.

5. Transportation Machinery: Vehicles like cars, planes, and ships for moving people and goods.

6. Electronic Machinery: Devices such as computers and robotics for automation.

7. Medical Machinery: Equipment used in healthcare, like MRI machines and surgical tools.

Each type serves specific purposes, contributing to advancements in various fields.

Machinery plays a pivotal role in our lives by:

1. Enhancing Efficiency: Automates tasks, saving time and increasing productivity.

2. Improving Precision: Enables accurate and consistent performance in various industries.

3. Aiding Economic Growth: Drives industrial development and contributes to economic progress.

4. Simplifying Daily Tasks: From household appliances to transportation, machinery makes daily life more convenient.

5. Advancing Technology:Machinery is at the core of technological innovation, shaping modern society.

6. Enabling Medical Progress: Supports advancements in healthcare with diagnostic and treatment equipment.

7. Boosting Agriculture:Farm machinery ensures efficient crop production, addressing food supply needs.

Overall, machinery significantly influences and improves the quality of human life in numerous aspects.

Importing and exporting machinery have several advantages:

1. Access to Technology: Countries can acquire advanced machinery and technology that might not be locally available, boosting industrial capabilities.

2. Economic Growth: Machinery trade contributes to economic development by creating jobs, stimulating industries, and fostering innovation.

3. Specialization:Countries can specialize in producing specific types of machinery, leading to efficiency and cost-effectiveness.

4. Global Collaboration:International trade of machinery encourages collaboration and exchange of expertise between nations.

5. Diversification:Importing and exporting machinery allow countries to diversify their industrial base, reducing dependence on a specific sector.

However, challenges such as ensuring quality standards, regulatory compliance, and environmental considerations should be addressed to make the process effective and sustainable.

The beneficial effects of importing and exporting machinery include:

1. Technological Advancement: Access to cutting-edge machinery enhances productivity and efficiency, driving technological progress.

2. Economic Growth: Machinery trade stimulates economic development, creating jobs, increasing industrial output, and contributing to overall prosperity.

3. Global Competitiveness:Exposure to international markets fosters competitiveness, encouraging industries to improve their products and processes.

4. Resource Optimization:Countries can specialize in producing what they excel at, optimizing resource utilization and promoting efficiency.

5. Innovation and Knowledge Transfer: International trade facilitates the exchange of ideas and expertise, fostering innovation and knowledge transfer between nations.

6. Infrastructure Development: Machinery imports can support infrastructure projects, contributing to the development of essential facilities like transportation and energy.

Overall, the exchange of machinery on the global stage has a positive impact on economic, technological, and social aspects.

Machinery is essential in industrial services for several reasons:

1. Automation and Efficiency: Machinery automates repetitive tasks, improving efficiency and reducing the need for manual labor.

2. Precision and Consistency: Industrial machinery ensures precise and consistent manufacturing processes, leading to higher quality products.

3. Increased Productivity: Automated machinery can work continuously, increasing production rates and overall output.

4. Safety: Machinery is often designed to handle hazardous tasks, reducing risks to human workers and improving workplace safety.

5. Cost-effectiveness: Over time, machinery can lead to cost savings through increased productivity, reduced labor costs, and minimized errors.

6. Innovation and Technological Advancements: Industrial machinery drives innovation by incorporating the latest technologies, keeping industries competitive.

7. Scale of Production: Machinery enables large-scale production, allowing industries to meet growing demand and scale their operations.

In summary, machinery is crucial in industrial services for streamlining operations, enhancing safety, and driving innovation, ultimately contributing to the growth and success of industrial sectors.

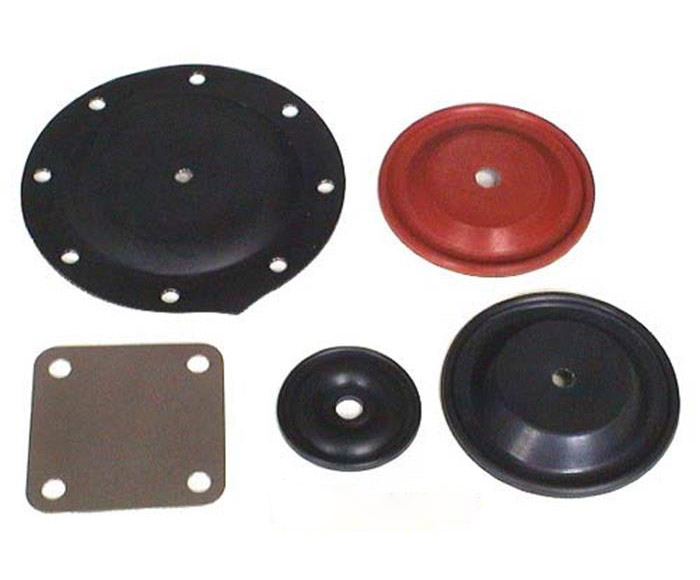

Machineries can break down due to various reasons, including:

1. Wear and Tear: Continuous use leads to natural wear and tear of components, affecting their functionality over time.

2. Lack of Maintenance: Inadequate or irregular maintenance can result in the deterioration of machinery, increasing the likelihood of breakdowns.

3. Overloading: Exceeding the specified capacity or operating conditions can stress the machinery, leading to failures.

4. Environmental Factors: Exposure to harsh conditions such as extreme temperatures, humidity, or corrosive substances can damage machinery.

5. Faulty Components:Manufacturing defects or the use of substandard materials can lead to the failure of individual components.

6. Incorrect Operation:Improper use or operation of machinery, such as ignoring user manuals, can contribute to breakdowns.

7. Aging: Machinery has a finite lifespan, and as it ages, the likelihood of breakdowns increases.

Understanding and addressing these factors through regular maintenance and proper operation can help prevent breakdowns and prolong the life of machinery.

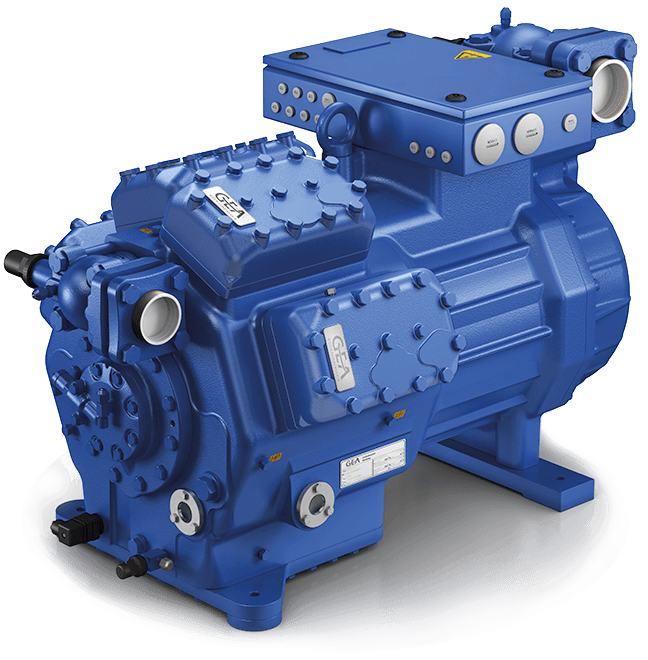

Equipment used in machinery can vary widely depending on the industry and application.

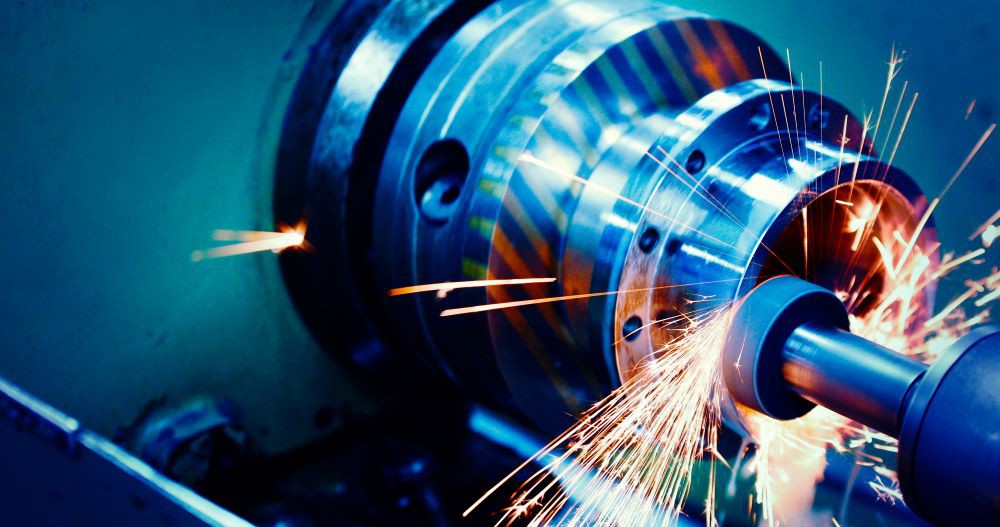

Common types of equipment found in machinery include:

1. Motors and Engines: Power sources providing mechanical energy to drive machinery.

2. Gears and Gearboxes: Transmit and control the speed and torque of rotating machinery components.

3. Bearings:Support and facilitate smooth movement between machine parts.

4. Pumps and Compressors:Devices for fluid movement or compression, commonly used in various industrial processes.

5. Valves: Control the flow of fluids or gases within machinery systems.

6. Sensors and Control Systems: Monitor and regulate the operation of machinery, ensuring optimal performance.

7. Conveyors: Transport materials within a manufacturing or processing facility.

8. Cutting Tools: Used in machining processes for shaping and cutting materials.

9. Robotic Arms:Automation components used in industries for tasks like welding, assembly, and handling.

10. Cooling Systems: Maintain optimal operating temperatures for machinery.

These components work together to perform specific functions within different types of machinery, contributing to the overall operation and efficiency of the equipment.

Machinery encompasses a wide range of mechanical devices, from simple tools to complex industrial equipment. It involves the use of mechanical power to perform tasks, making processes more efficient and often reducing manual labor. Industries like manufacturing, agriculture, and transportation heavily rely on machinery for increased productivity and precision. Advances in technology continue to shape and improve the capabilities of machinery across various sectors.

Machinery comes in various types, including:

2. Industrial Machines:Complex equipment used in manufacturing and production processes.

3. Construction Machinery: Excavators, bulldozers, and cranes for building and infrastructure.

4. Agricultural Machinery: Tractors, combines, and plows for farming activities.

5. Transportation Machinery: Vehicles like cars, planes, and ships for moving people and goods.

6. Electronic Machinery: Devices such as computers and robotics for automation.

7. Medical Machinery: Equipment used in healthcare, like MRI machines and surgical tools.

Machinery plays a pivotal role in our lives by:

2. Improving Precision: Enables accurate and consistent performance in various industries.

3. Aiding Economic Growth: Drives industrial development and contributes to economic progress.

4. Simplifying Daily Tasks: From household appliances to transportation, machinery makes daily life more convenient.

5. Advancing Technology:Machinery is at the core of technological innovation, shaping modern society.

6. Enabling Medical Progress: Supports advancements in healthcare with diagnostic and treatment equipment.

7. Boosting Agriculture:Farm machinery ensures efficient crop production, addressing food supply needs.

Importing and exporting machinery have several advantages:

The beneficial effects of importing and exporting machinery include:

FAQs

How can we know the spare parts of the industrial machinery are available ?

Ask supplier about spare parts availability, lead time, parts list, and customer references.

Is it reasonable to repair the broken-down machinery?

Depends on the extent/cost of repairs and the age of machinery.

Why is machinery useful?

Efficiency, automation, increased productivity.

Why do machines break down?

Wear, tear, lack of maintenance, and age.