Industrial Valves

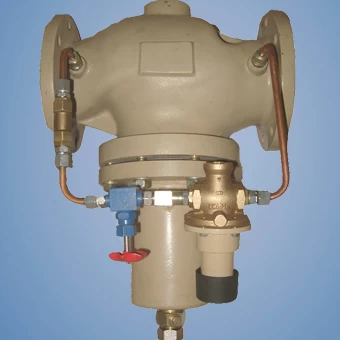

Industrial valves are essential components in various industrial processes, playing a critical role in controlling the flow of liquids, gases, and slurries within pipelines and systems. These valves are designed to regulate, isolate, and direct the movement of substances in a precise and controlled manner, contributing to the efficiency and safety of industrial operations.

One of the fundamental types of industrial valves is the gate valve. Known for its on/off control capability, the gate valve uses a gate-like disc to either block or allow the flow of fluids. This design provides a tight seal when closed and minimal resistance when fully open, making it suitable for applications where a straight-line flow is necessary.

Ball valves are another prevalent type, featuring a spherical closure element. They offer quick and reliable control, allowing for a full or partial opening to regulate flow. Ball valves are versatile and find applications in various industries, including oil and gas, chemical processing, and water treatment.

The butterfly valve, characterized by a disk rotating on an axis, is valued for its quick and efficient operation. These valves are commonly used in large-diameter applications, providing a cost-effective solution for regulating flow in pipelines with reduced pressure drops.

Beyond these, check valves ensure one-way flow, preventing backflow and maintaining system integrity. Relief valves safeguard equipment by releasing excess pressure, while control valves modulate flow based on signals from external devices, optimizing process performance.

Industrial valves find extensive use across various sectors and applications:

1. Oil and Gas Industry: In upstream, midstream, and downstream operations, valves regulate the flow of crude oil, natural gas, and refined products within pipelines, refineries, and extraction facilities.

2. Chemical Processing: Valves control the movement of chemicals in chemical plants, ensuring precise mixing, distribution, and containment during various processes.

3. Water and Wastewater Treatment: Valves are integral in managing the flow of water and chemicals in treatment plants, controlling the distribution and disposal of clean and treated water.

4. Power Generation: In power plants, valves control the flow of steam, water, and gases, contributing to efficient and safe energy production.

5. Manufacturing: Industrial valves play a role in manufacturing processes, regulating the flow of fluids and gases in machinery and production lines.

6. Mining: Valves are used in mining operations to control the flow of slurry, water, and other substances during mineral processing.

7. Pulp and Paper Industry: Valves regulate the flow of chemicals, water, and pulp in paper mills, contributing to the production of paper and related products.

8. Agriculture: In irrigation systems and agricultural machinery, valves control the flow of water, fertilizers, and other substances essential for crop cultivation.

9. Pharmaceuticals: Valves contribute to the precise control of fluids in pharmaceutical manufacturing processes, ensuring the accuracy and quality of pharmaceutical products.

10. Food and Beverage Industry: Valves play a role in controlling the flow of liquids and gases in food and beverage processing, maintaining hygiene and product quality.

These diverse applications highlight the versatility of industrial valves, making them essential components in numerous industries where the controlled flow of fluids and gases is critical for efficient and safe operations.

In the petrochemical industry, industrial valves play a crucial role in ensuring the safe and efficient processing of hydrocarbons and the production of various chemical products. Here are key roles they play in this industry:

1. Flow Control: Valves regulate the flow of crude oil, gases, and various chemical feedstocks within pipelines and processing units. This control is essential for maintaining optimal operating conditions and preventing overpressure situations.

2. Isolation: Valves provide the ability to isolate different sections of the processing system. This isolation is crucial during maintenance, emergencies, or when specific units need to be taken offline without affecting the entire operation.

3. Pressure Regulation: Valves help manage and control pressure levels in different stages of the petrochemical process. This is vital for ensuring the safety of equipment and personnel and optimizing the efficiency of various reactions and separations.

4.Safety Relief: Specialized safety relief valves release excess pressure to prevent equipment damage and ensure the safety of the entire system. They act as a last line of defense against overpressure situations.

5. Temperature Control: Valves are employed to control the temperature of processes by regulating the flow of cooling or heating media. This is particularly important in reactions that are sensitive to temperature changes.

In essence, industrial valves in the petrochemical industry are integral to maintaining control, safety, and efficiency throughout the complex processes involved in the extraction, refining, and production of chemicals and fuels. Their strategic placement and precise operation are essential for the smooth functioning of petrochemical facilities.

In the context of exporting, industrial valves play a significant role in several aspects related to the transportation and distribution of various commodities. Here are key roles they play in the export process:

1. Shipping and Transportation: Valves are used in tanker vessels and shipping containers to control the flow of liquids and gases, ensuring safe and efficient transport of exported goods, including chemicals and petroleum products.

2.Loading and Unloading Terminals: Valves are critical components in loading and unloading terminals, facilitating the transfer of products between different modes of transportation, such as ships, trucks, and pipelines.

3. Storage Facilities: Valves play a role in storage tanks and terminals where exported products are stored before shipment. They contribute to the controlled filling and emptying of storage vessels.

4. Pipeline Infrastructure: In cases where pipelines are involved in the transportation of exported goods, valves regulate the flow, provide isolation points, and contribute to the overall integrity and safety of the pipeline network.

5.Quality Control: Valves are employed in sampling and quality control processes, allowing for representative samples to be taken during the export process to ensure compliance with international standards.

6. Safety Compliance: Industrial valves are essential for meeting safety and environmental regulations. They contribute to emergency shutdown systems and pressure relief mechanisms to prevent accidents during transportation.

7. Customs and Inspection: Valves may be used in systems designed for customs inspection, allowing authorities to monitor and inspect the contents of containers or tanks during the export process.

8. Terminal Operations: At export terminals, valves are crucial for managing the flow of products, providing flexibility in routing, and ensuring that various products can be processed and exported efficiently.

In summary, industrial valves are integral to the export process, ensuring the safe, efficient, and compliant transportation of goods. Their roles extend from loading facilities to transportation vessels, storage terminals, and distribution networks, contributing to the reliability and integrity of the entire export supply chain.

In the petrochemical industry, industrial valves play a crucial role in ensuring the safe and efficient processing of hydrocarbons and the production of various chemical products. Here are key roles they play in this industry:

In the context of exporting, industrial valves play a significant role in several aspects related to the transportation and distribution of various commodities. Here are key roles they play in the export process:

FAQs

How many types of valves are there in industry?

Numerous, including gate, ball, globe, butterfly, check, and control valves.

Why are valves important in industry?

Critical for flow control, safety, and efficiency in managing liquids, gases, and chemicals in various industrial processes.

How to identify an industrial valve?

Identify by type, materials, size, connection methods, and specific features such as actuation mechanisms or pressure ratings.

What are the industrial uses of valves?

Used in various industries for controlling fluid and gas flow, including oil and gas, chemical processing, water treatment, power generation, and manufacturing.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14