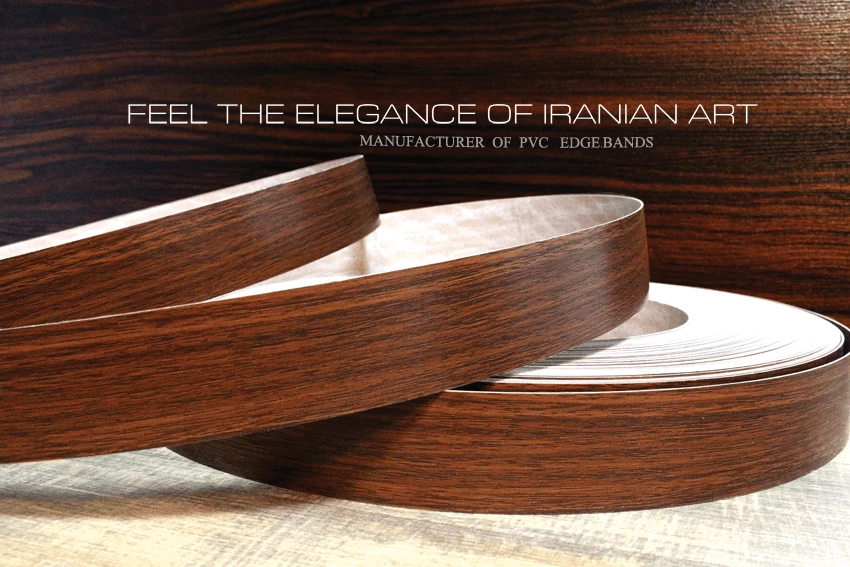

Edge banding

Edge banding, also known as edge band, edge tape, or edge strip, is a thin strip of material applied to the exposed edges of furniture, cabinetry, countertops, and other surfaces to create a finished appearance and protect the underlying material from damage. Edge banding serves both functional and aesthetic purposes, providing a seamless and durable edge finish while enhancing the overall appearance of the surface.

Here are some key aspects of edge banding:

1. Materials: Edge banding strips are typically made from various materials, including PVC (polyvinyl chloride), ABS (acrylonitrile butadiene styrene), wood veneer, melamine, and metal. Each material offers unique characteristics in terms of durability, appearance, and suitability for different applications.

2. Application: Edge banding is applied to the exposed edges of substrates such as plywood, particleboard, MDF (medium-density fiberboard), or solid wood using an adhesive. The banding is trimmed to size and then affixed to the edge of the substrate, creating a seamless and finished look.

3. Types: Edge banding strips come in different types and styles to suit various preferences and applications. Some common types include:

- Solid color PVC or ABS edge banding: Available in a wide range of colors to match or complement the surface material.

- Wood veneer edge banding: Made from thin slices of real wood veneer for a natural wood appearance.

- Metallic edge banding: Made from metal foils or laminates for a modern and decorative finish.

- Pre-glued or iron-on edge banding: Features a heat-activated adhesive backing for easy application using a hot iron or edge banding machine.

4. Thickness and Width: Edge banding strips come in different thicknesses and widths to accommodate various edge profiles and dimensions. Common thicknesses range from 0.5mm to 3mm, while widths can vary depending on the application and design requirements.

5. Applications: Edge banding is commonly used in furniture manufacturing, cabinetry, millwork, countertops, shelving, and other woodworking projects. It provides a professional and polished finish to edges, concealing any exposed plywood or particleboard layers and protecting the substrate from moisture, impact, and wear.

Overall, edge banding is a versatile and practical solution for achieving a clean and finished look on furniture and woodworking projects, enhancing durability and aesthetics simultaneously.

Here are several types of edge banding commonly used in woodworking and furniture manufacturing:

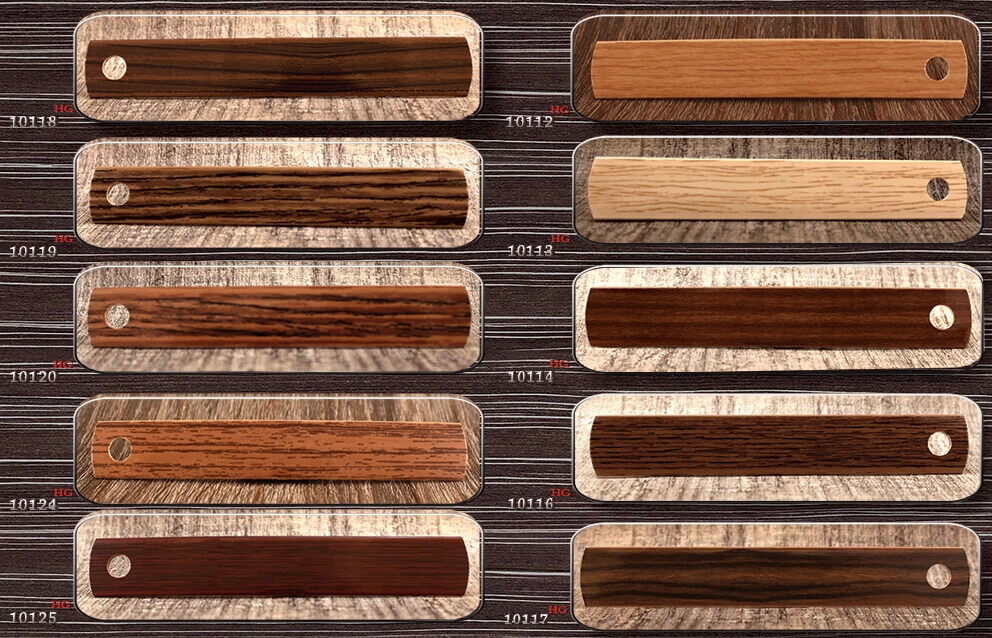

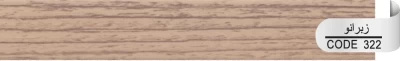

1. PVC Edge Banding: PVC (polyvinyl chloride) edge banding is one of the most common types. It is made of PVC material and is available in a wide range of colors, patterns, and textures. PVC edge banding is durable, flexible, and resistant to moisture, making it suitable for various applications in furniture, cabinetry, countertops, and shelving.

2. Wood Veneer Edge Banding: Wood veneer edge banding is made from thin slices of real wood veneer, typically sourced from hardwood species like oak, maple, cherry, or walnut. It provides a natural wood appearance and can be stained or finished to match the surface material. Wood veneer edge banding is popular for high-end furniture and woodworking projects.

3. Melamine Edge Banding: Melamine edge banding is made of resin-impregnated paper or vinyl that is thermally fused to the substrate's edges. It is available in solid colors and wood grain patterns and is commonly used in furniture and cabinetry constructed with melamine or laminate panels.

4. Metal Edge Banding:** Metal edge banding is made from aluminum or stainless steel and provides a sleek and modern finish. It is highly durable, resistant to corrosion, and often used in contemporary furniture designs, architectural applications, and commercial interiors.

5. Acrylic Edge Banding: Acrylic edge banding, also known as PMMA (polymethyl methacrylate) edge banding, offers a high-gloss and seamless finish. It is durable, scratch-resistant, and available in a variety of colors and finishes. Acrylic edge banding is commonly used in modern furniture designs and interior decor.

6. Polyester Edge Banding: Polyester edge banding is made from polyester resin and offers excellent durability and resistance to chemicals and heat. It is available in solid colors and wood grain patterns and is suitable for a wide range of applications in furniture and cabinetry.

7. Thermoplastic Edge Banding: Thermoplastic edge banding is made from thermoplastic polymers like ABS (acrylonitrile butadiene styrene) or PVC. It is flexible, easy to work with, and available in various colors and textures. Thermoplastic edge banding is commonly used in furniture, cabinets, and fixtures.

These are some of the different kinds of edge banding commonly used in woodworking and furniture manufacturing, each offering unique features and advantages for different applications and design preferences.

PVC (polyvinyl chloride) edge banding is a widely used type of edge banding in woodworking and furniture manufacturing. It is made from PVC material and is available in a variety of colors, patterns, and textures to match or complement the surface material. Here are some key features and benefits of PVC edge banding:

1. Durability: PVC edge banding is highly durable and resistant to moisture, abrasion, and impact, making it suitable for various applications in furniture, cabinetry, countertops, and shelving.

2. Flexibility: PVC edge banding is flexible and can be easily bent to fit curved or irregularly shaped edges, providing a seamless finish.

3. Ease of Application: PVC edge banding is easy to apply using adhesive and can be trimmed to size with standard woodworking tools like edge trimmers or routers.

4. Wide Range of Colors and Patterns: PVC edge banding is available in a wide range of solid colors, wood grain patterns, and textures, allowing for customization and matching of different surface materials.

5. Uniform Appearance: PVC edge banding provides a uniform and consistent appearance, concealing any exposed plywood or particleboard layers and creating a clean and finished look.

6. Cost-Effective: PVC edge banding is cost-effective compared to other types of edge banding materials like wood veneer or metal, making it a popular choice for budget-conscious projects.

7. Low Maintenance: PVC edge banding is easy to clean and maintain, requiring only regular wiping with a damp cloth to remove dust and dirt.

8. Environmentally Friendly Options: Some PVC edge banding products are manufactured using eco-friendly processes and materials, reducing environmental impact.

_1710351557.png)

Overall, PVC edge banding is a versatile and practical solution for achieving a professional and durable edge finish in woodworking and furniture projects. It offers a wide range of colors, patterns, and textures to suit different design preferences and provides excellent durability and performance in various applications.

- Solid color PVC or ABS edge banding: Available in a wide range of colors to match or complement the surface material.

- Wood veneer edge banding: Made from thin slices of real wood veneer for a natural wood appearance.

- Metallic edge banding: Made from metal foils or laminates for a modern and decorative finish.

- Pre-glued or iron-on edge banding: Features a heat-activated adhesive backing for easy application using a hot iron or edge banding machine.

Here are several types of edge banding commonly used in woodworking and furniture manufacturing:

PVC (polyvinyl chloride) edge banding is a widely used type of edge banding in woodworking and furniture manufacturing. It is made from PVC material and is available in a variety of colors, patterns, and textures to match or complement the surface material. Here are some key features and benefits of PVC edge banding:

_1710351557.png)

FAQs

What is the edge band known as?

Edge banding, also known as edge band, edge tape, or edge strip, is a thin strip of material applied to the exposed edges of furniture

How is the edge band applied?

Edging is applied to exposed edges of substrate layers such as plywood, chipboard, MDF (medium density fiberboard) or solid wood using adhesive.

What is the common thickness for edging?

Common thicknesses range from 0.5mm to 3mm,

What is thermoplastic edge banding made of?

Thermoplastic edge banding is made from thermoplastic polymers like ABS (acrylonitrile butadiene styrene) or PVC.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14