Coating & Paint

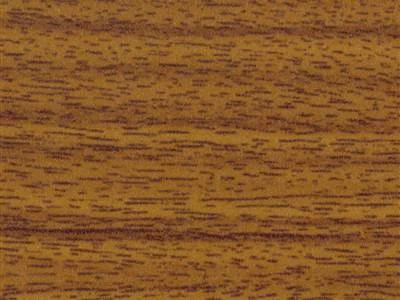

Coatings are materials applied to surfaces to protect, beautify, or enhance their properties. They come in various forms such as paints, varnishes, lacquers, and sealants, and they serve a wide range of purposes including corrosion protection, waterproofing, insulation, and decoration. Coatings can be applied to surfaces such as metal, wood, concrete, and plastic, and they are commonly used in industries like construction, automotive, aerospace, and marine.

Waterproof coatings are specialized coatings designed to provide a protective barrier against water penetration. They are applied to surfaces to prevent water ingress and protect against moisture damage. Waterproof coatings can be used on various surfaces including roofs, walls, concrete structures, and even fabrics and textiles.

These coatings typically form a seamless, impermeable layer that prevents water from seeping through. They are commonly used in areas prone to water exposure such as basements, bathrooms, roofs, and decks. Waterproof coatings come in various forms including liquid-applied coatings, membrane systems, cementitious coatings, and bituminous coatings.

Some common types of waterproof coatings include:

1. Acrylic Waterproof Coatings : These coatings are based on acrylic polymers and are suitable for both interior and exterior applications. They are flexible, durable, and easy to apply, making them ideal for a wide range of surfaces.

2. Polyurethane Waterproof Coatings : Polyurethane coatings offer excellent waterproofing properties along with high abrasion resistance. They are commonly used in areas subjected to heavy traffic or mechanical wear.

3. Epoxy Waterproof Coatings : Epoxy coatings provide superior adhesion and chemical resistance, making them suitable for demanding environments such as industrial floors, tanks, and containment areas.

4. Silicone Waterproof Coatings : Silicone coatings offer excellent UV resistance and weathering properties, making them ideal for outdoor applications. They are commonly used in roof coatings and facades.

5. Bituminous Waterproof Coatings : Bituminous coatings, also known as asphalt coatings, are based on bitumen and provide excellent waterproofing properties. They are commonly used in below-grade applications such as foundations and basements.

When choosing a waterproof coating, it's essential to consider factors such as substrate type, environmental conditions, application method, and desired performance characteristics. Additionally, proper surface preparation and application techniques are crucial for ensuring the effectiveness and durability of the waterproofing system.

Insulation coatings are specialized coatings designed to provide thermal insulation by reducing heat transfer through surfaces. These coatings are applied to various substrates to enhance energy efficiency, reduce heat loss or gain, and improve overall comfort levels in buildings, equipment, or industrial processes.

Insulation coatings come in different forms and compositions, each offering specific properties and performance characteristics. Some common types of insulation coatings include:

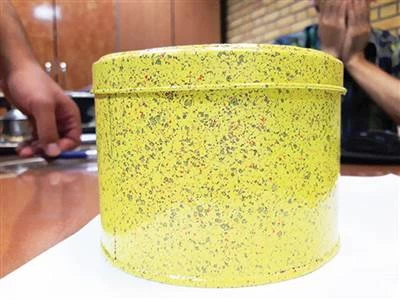

1. Ceramic Insulation Coatings : These coatings contain ceramic microspheres or nanoparticles dispersed in a binder material. They form a thin, thermal barrier that reflects heat away from surfaces, thus reducing thermal conductivity and preventing heat transfer. Ceramic insulation coatings are often used in industrial applications, building exteriors, and equipment insulation.

2. Elastomeric Insulation Coatings : Elastomeric coatings are flexible, rubber-like coatings that provide both thermal insulation and waterproofing properties. They are commonly used on roofs, walls, and other building surfaces to improve energy efficiency and protect against moisture intrusion.

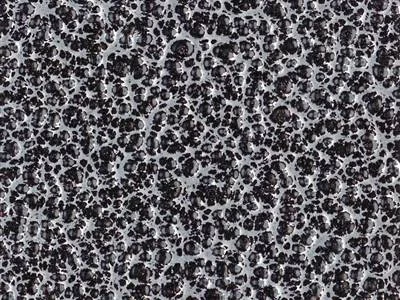

3. Aerogel Insulation Coatings: Aerogels are lightweight, nanoporous materials with excellent thermal insulation properties. Aerogel-based coatings are applied as thin layers to surfaces to provide superior thermal insulation while minimizing weight and thickness. They are used in aerospace, automotive, and building insulation applications where space and weight considerations are critical.

4. Reflective Insulation Coatings : These coatings contain reflective pigments or additives that reflect radiant heat, reducing heat absorption by surfaces. Reflective insulation coatings are often used on roofs, walls, and windows to improve energy efficiency and reduce cooling loads in buildings.

5. Foam Insulation Coatings : Foam insulation coatings are spray-applied polyurethane or polyisocyanurate foam materials that expand and cure to form a seamless, insulating layer. They are used for thermal insulation in buildings, refrigeration systems, and industrial equipment.

6. Intumescent Insulation Coatings : Intumescent coatings are fire-resistant coatings that expand and form an insulating char layer when exposed to high temperatures. They are used to protect structural steel, concrete, and other building materials from fire and heat damage while providing thermal insulation.

Insulation coatings are applied using various methods such as spray, brush, or roller application, depending on the coating type and substrate. Proper surface preparation and application techniques are essential to ensure the effectiveness and durability of insulation coatings.

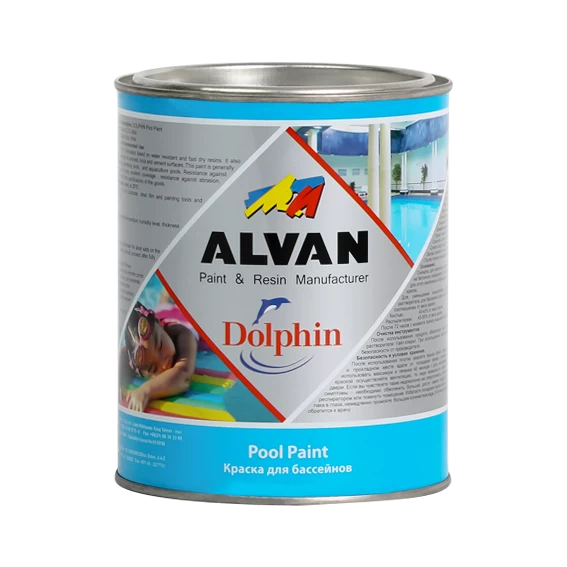

Paint is a liquid substance applied to surfaces to add color, protect, or decorate them. It consists of pigments, binders, solvents, and additives. Paint can be applied to various surfaces such as walls, wood, metal, plastic, and more. There are different types of paint based on their composition and application method, including:

1. Water-based Paint : Also known as latex or acrylic paint, water-based paint uses water as a solvent and is commonly used for interior and exterior walls, furniture, and crafts. It dries quickly and emits fewer fumes than oil-based paint.

2. Oil-based Paint: Oil-based paint uses mineral spirits or other solvents as a base and is known for its durability and glossy finish. It is suitable for surfaces exposed to high wear and tear, such as trim, doors, and metal surfaces.

3. Enamel Paint : Enamel paint is a type of oil-based paint known for its hard, glossy finish. It is commonly used for metal surfaces, cabinets, and trim.

4. Spray Paint : Spray paint is a type of paint packaged in a pressurized can and applied using a spray nozzle. It is convenient for painting small objects, outdoor furniture, and intricate surfaces.

5. Primer : Primer is a preparatory coating applied before painting to improve adhesion, enhance durability, and provide a uniform surface for paint application. It helps paint adhere better to surfaces and improves coverage.

6. Epoxy Paint : Epoxy paint is a durable coating that consists of epoxy resin and a curing agent. It is commonly used for floors, countertops, and metal surfaces that require high durability and chemical resistance.

7. Chalk Paint : Chalk paint is a type of decorative paint known for its matte finish and velvety texture. It is often used for furniture refinishing and DIY projects, and it can be distressed or waxed for a vintage look.

8. Acrylic Paint : Acrylic paint is a type of water-based paint that uses acrylic resin as a binder. It dries quickly, is water-resistant when dry, and is commonly used for crafts, canvas painting, and decorative projects.

_1710699897.jpg)

These are just a few examples of the many types of paint available, each with its own characteristics and applications. The choice of paint depends on factors such as the surface to be painted, desired finish, durability requirements, and environmental considerations.

_1710699897.jpg)

FAQs

Where are the Coatings used?

surfaces such as metal, concrete, and plastic, and they are commonly used in industries like construction, automotive, aerospace, and marine.

Is there a waterproof coating?

yes Waterproof coatings are specialized coatings designed to provide a protective barrier against water penetration

It consists of pigments, binders, solvents, and additives

It consists of pigments, binders, solvents, and additives

At what surfaces paints can be used?

Paint can be applied to various surfaces such as walls, wood, metal, plastic, and more

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

.webp)

.webp)

.webp)