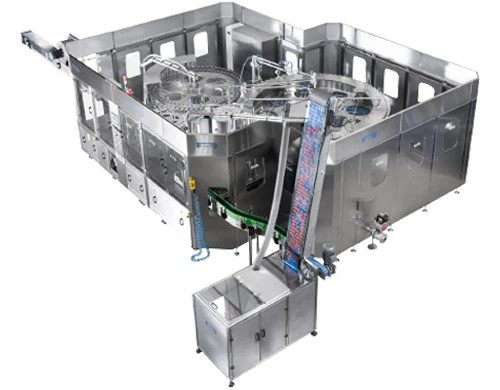

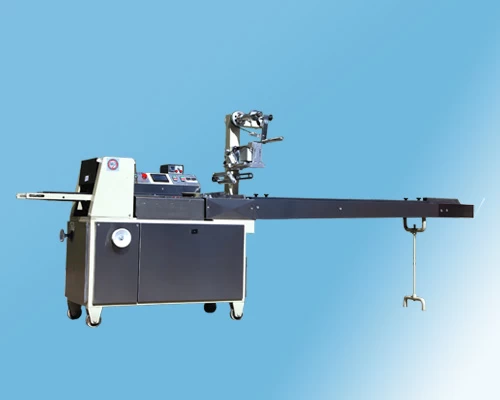

Packaging Machines

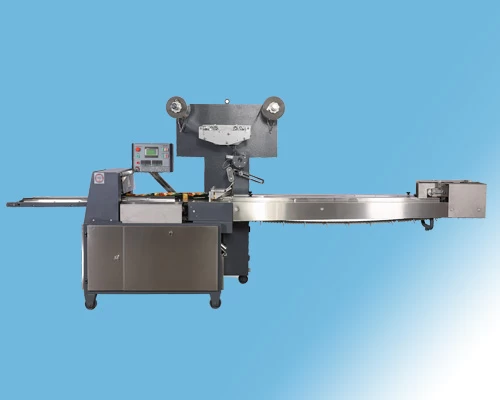

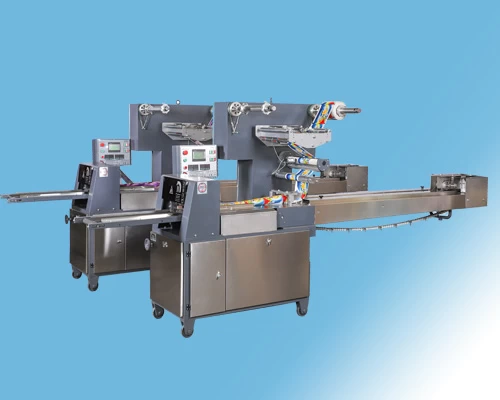

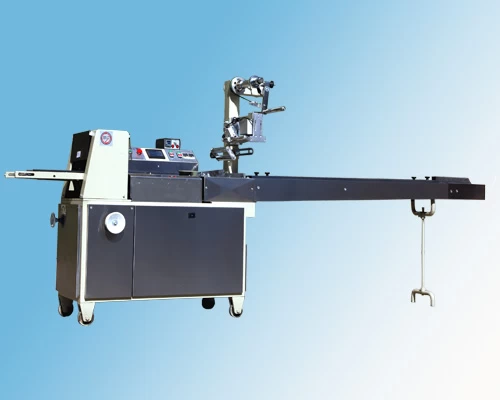

Packaging Machines is an automated device designed to efficiently package products for distribution or sale. It streamlines the packaging process, enhancing speed and precision while reducing manual labor. These machines come in various types, such as vertical form-fill-seal, horizontal form-fill-seal, and shrink wrap machines, catering to different packaging needs across industries.

Packaging Machines find applications across a wide range of industries where efficient and standardized packaging is essential. Here are some industries and products that commonly utilize Packaging Machines:

1. Food Industry:

- Snack Foods: Chips, nuts, and candies often require packaging to maintain freshness and extend shelf life. Vertical form-fill-seal machines are commonly used for these products.

- Bakery Products: Items like cookies, cakes, and bread benefit from packaging machines to preserve texture and flavor.

2. Beverage Industry:

- Liquid Products:Beverages like water, juices, and soft drinks often use packing machines to fill and seal bottles or pouches.

3. Pharmaceuticals:

- Medications: Pharmaceuticals need precise and sterile packaging. Blister packaging machines and automatic cartoners are used for packaging tablets, capsules, and vials.

4. Cosmetics and Personal Care:

- Cosmetic Products: Items like creams, lotions, and makeup often require packaging machines for accurate dispensing and sealing.

5. Household Products:

- Cleaning Agents: Detergents, soaps, and other cleaning products benefit from efficient packaging to prevent leakage and ensure product integrity.

6. Electronics:

- Electronic Components: Fragile electronic items are often packaged using protective materials and precise sealing methods.

7. Textiles:

- Clothing and Fabrics: Packing machines help in efficiently packaging textiles, ensuring they reach customers in good condition.

8. Automotive:

- Spare Parts: Small automotive components are often packaged using automated machines to ensure they are protected during transportation.

9. Hardware and Tools:

- Fasteners and Small Tools: Items like nuts, bolts, and screws are efficiently packaged using packing machines.

10. Retail Products:

- Various Items: A wide range of retail products, from toys to stationery, benefit from packing machines to streamline the packaging process and maintain consistency.

Packaging Machines are versatile and can be adapted to suit the specific needs of different industries, providing efficiency, cost-effectiveness, and improved product presentation. They contribute to minimizing human error, reducing waste, and meeting the growing demands of modern production environments.

The purpose of a packaging machine is multi-faceted and crucial in modern industrial processes. Here's a comprehensive explanation:

1. Efficiency and Speed:

- Automation: Packaging machines automate the process of wrapping, sealing, and labeling products, significantly speeding up the packaging line compared to manual methods.

- High Throughput:These machines can handle a large volume of products efficiently, ensuring quick and consistent packaging, which is especially crucial in industries with high production demands.

2. Consistency and Precision:

- Standardization: Packaging machines ensure uniformity in the packaging process, maintaining consistent product presentation and quality.

- Accurate Measurements: They provide precise measurements for filling containers, reducing variations and minimizing product wastage.

3. Product Protection:

- Preservation: Packaging machines help protect products from external elements such as air, moisture, and contaminants, thereby extending shelf life and maintaining product freshness.

- Fragile Items:Delicate or breakable items are handled with care, reducing the risk of damage during packaging and transportation.

4. Cost Efficiency:

- Labor Savings: Automation reduces the need for manual labor in packaging processes, cutting down on labor costs and minimizing the risk of human errors.

- Material Efficiency: Packaging machines optimize the use of packaging materials, reducing waste and contributing to cost-effectiveness.

5. Hygiene and Sterility:

- Clean and Sterile Environment: Particularly crucial in pharmaceutical and food industries, packaging machines operate in controlled environments, ensuring hygiene and preventing contamination.

- Sealed Packaging:These machines create airtight seals, preventing exposure to external elements and maintaining the integrity of the packaged products.

In summary, packaging machines serve as integral components in modern manufacturing processes, addressing various needs like efficiency, consistency, product protection, cost-effectiveness, and regulatory compliance. Their role extends beyond mere containment, playing a vital part in ensuring that products reach consumers in optimal condition while meeting industry-specific requirements.

packaging machinery is commonly exported globally. Manufacturers of packaging machinery often engage in international trade to supply their equipment to industries worldwide. Several factors contribute to the widespread export of packaging machinery:

1. Global Demand: The demand for packaging machinery exists in various industries across the globe, including food and beverages, pharmaceuticals, cosmetics, electronics, and more. As a result, manufacturers seek opportunities to tap into diverse markets.

2. Technology Transfer: Countries with advanced packaging technology may export machinery to regions seeking to upgrade their manufacturing capabilities. This technology transfer helps enhance production efficiency and quality.

3. Specialized Equipment: Some packaging machinery manufacturers specialize in producing equipment tailored to specific industries or products. These specialized machines may be in demand internationally, driving export activities.

4. Economic Considerations: Exporting packaging machinery can be financially beneficial for manufacturers. It allows them to reach larger customer bases, diversify revenue streams, and potentially capitalize on economies of scale.

5. Trade Agreements: International trade agreements and collaborations between countries facilitate the export of machinery. Harmonized standards and reduced trade barriers make it easier for manufacturers to access foreign markets.

6. Customization for Local Markets: Packaging machinery can be adapted to meet specific regulatory and cultural requirements of different countries. This adaptability enhances the attractiveness of these machines in diverse markets.

Overall, the export of packaging machinery is a common practice, reflecting the global nature of manufacturing and the need for advanced, efficient, and specialized equipment across different industries worldwide.

The useful life of a packaging machine depends on several factors, and it can vary based on the type of machine, maintenance practices, technological advancements, and the level of wear and tear. Here are key considerations:

1. Type of Packaging Machine:

- Different types of packaging machines serve diverse purposes, from simple sealing machines to complex automated packaging lines. The complexity and sophistication of the machinery influence its lifespan.

2. Build Quality and Materials:

- High-quality materials and robust construction contribute to a longer lifespan. Machines built with durable materials and precision engineering tend to withstand the rigors of continuous operation.

3. Maintenance Practices:

- Regular maintenance is crucial for extending the lifespan of packaging machines. Proper lubrication, cleaning, and timely replacement of worn-out parts can prevent breakdowns and ensure optimal performance.

4. Usage Intensity:

- The frequency and duration of machine operation play a significant role. Machines subjected to heavy and continuous use may experience more wear and tear compared to those used sporadically.

5. Technological Advancements:

- Rapid advancements in technology may lead to obsolescence of older machines. Upgrading or replacing machinery to incorporate new features or automation capabilities can be a strategic decision to stay competitive.

6. Environmental Conditions:

- The operating environment influences the lifespan. Factors such as temperature, humidity, and exposure to corrosive substances can impact the longevity of the machine.

In summary, the useful life of a packaging machine is a dynamic concept influenced by a combination of factors. Regular maintenance and adherence to operational guidelines can help maximize the lifespan, while considerations of technological advancements and changing industry needs may lead to strategic decisions about replacement or upgrades over time.

FAQs

How many bags can the packaging machine make per minute?

The production capacity varies; it depends on the specific packaging machine model.

What is the purpose of packaging machine?

Automates packaging processes for efficiency, consistency, and product protection.

How do I choose a packaging machine?

Consider product type, production volume, packaging material, and budget when selecting a machine.

Which machine is used for packaging?

Various machines, such as form-fill-seal, shrink wrap, and cartoning machines, are used for packaging across industries.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

.webp)