Model: MS-SC 200

For transportation of food and medicine products

Transmission system: PVC food grade tape

Dimensions of the device: according to the order

How Conveyor Belt Systems Work. In a typical conveyor belt system, a belt forms a closed loop and stretches across two or more pulleys. This enables it to rotate continually. One of the pulleys (the drive pulley) moves the items from one place to another.

They are used to transport materials from one point to another, often over long distances. Conveyor belts can be made from a variety of materials, including PVC, polyester, cotton, and rubber. There are four main types of conveyor belts: flat belts, modular belts, timing belts, and V-belts.

Pneumatic conveyors, belt conveyors, bucket elevators, screw augers, and tubular drag conveyors are the most used types in the food industry. Each type serves specific needs, ensuring seamless and hygienic processes.

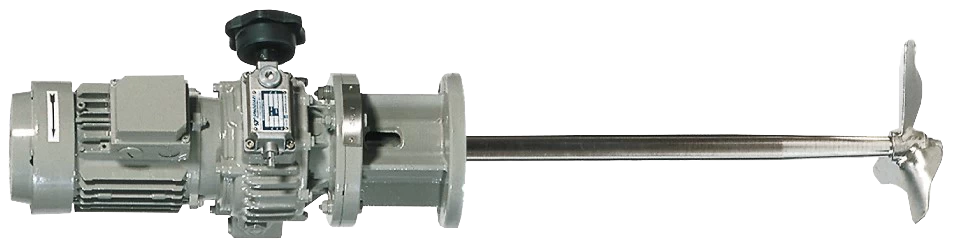

Food grade conveyor belts are made from materials that are non-toxic, non-absorbent, and resistant to bacteria growth, such as stainless steel mesh, plastic modular belts, or specialty materials like silicone. Drive system: The drive system consists of a motor, gearbox, and sprockets that power the conveyor.

A conveyor system is a fast and efficient mechanical handling apparatus for automatically transporting loads and materials within an area. This system minimizes human error, lowers workplace risks and reduces labor costs — among other benefits.

A belt conveyor, also called a conveyor belt, is a fairly simple conveyor with limited features mainly used to move bulk materials such as sand, salt and grain. Its simplicity makes it easy to use and also makes it one of the most common types of conveyors.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

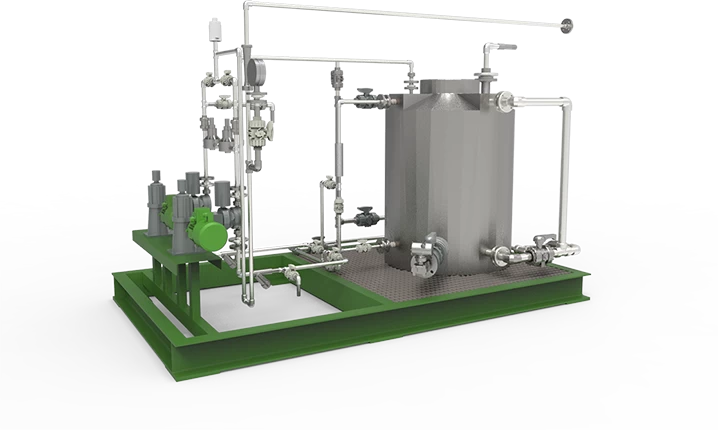

Chemical & Pharmaceutical Machinery

Chemical & Pharmaceutical Machinery