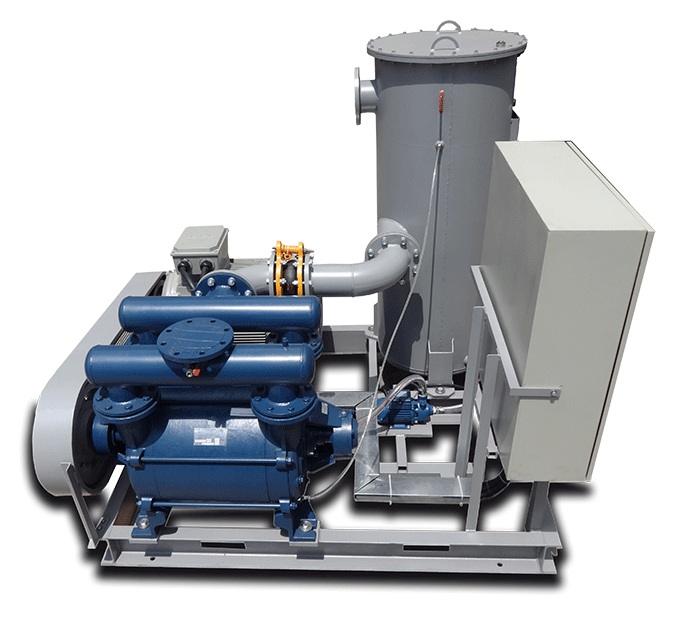

In fact, the screw compressor is a phenomenon between reciprocating compressors and centrifugal compressors, because both in terms of Positive Displacment, i.e. the positive displacement of the fluid by increasing its pressure, it has the property of reciprocating and dynamic compressors due to the continuity in Air movement... Therefore, these compressors are very suitable for pressurizing fluids.

Oil-free rotary screw compressor: External gears synchronize the position of the counter-rotating screw elements, and, because the rotors do not come in contact and create friction, no lubrication is needed within the compression chamber. As a result, the compressed air is oil-free.

Oil-lubricated compressors are typically more found in industries where air quality is not much of a concern, like – cement, metal, plastic or general manufacturing. In contrast, oil-free compressors are better for applications where clean, oil-free air is a top priority.

Screw compressor oil is essential for the compressor operation. Helps dissipate heat generated during compression, preventing overheating. If the temperature of the compressor is too high, the element or all rotating parts would be excessively stressed and the service life would be shortened.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Compressor

Compressor