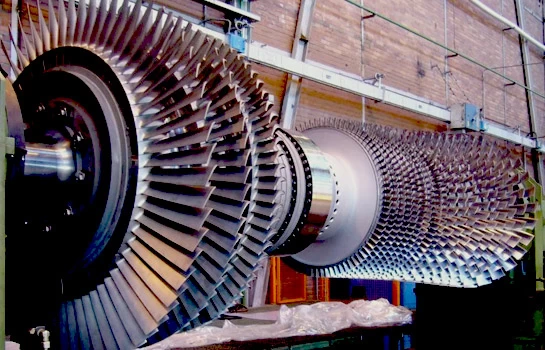

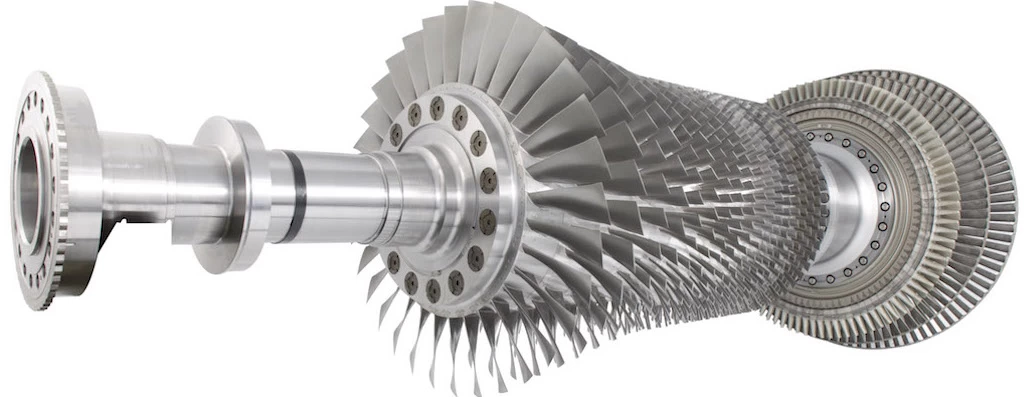

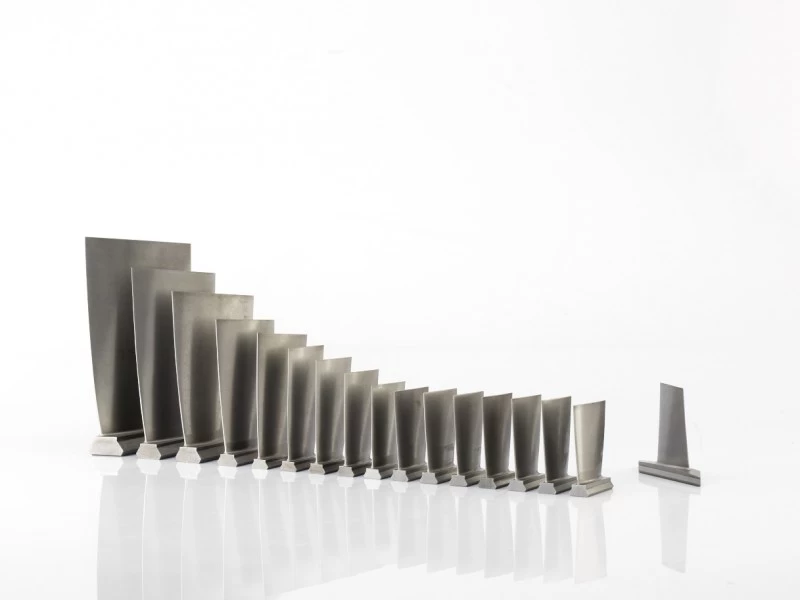

The screw compressor is actually a phenomenon between reciprocating compressors and centrifugal compressors, because both in terms of Positive Displacment, i.e. the positive displacement of the fluid by increasing its pressure, it has the properties of reciprocating and dynamic compressors due to the continuity of displacement. Air... Therefore, these compressors are very suitable for pressurizing fluids.

Screw compressor oil is essential for the compressor operation. Helps dissipate heat generated during compression, preventing overheating. If the temperature of the compressor is too high, the element or all rotating parts would be excessively stressed and the service life would be shortened.

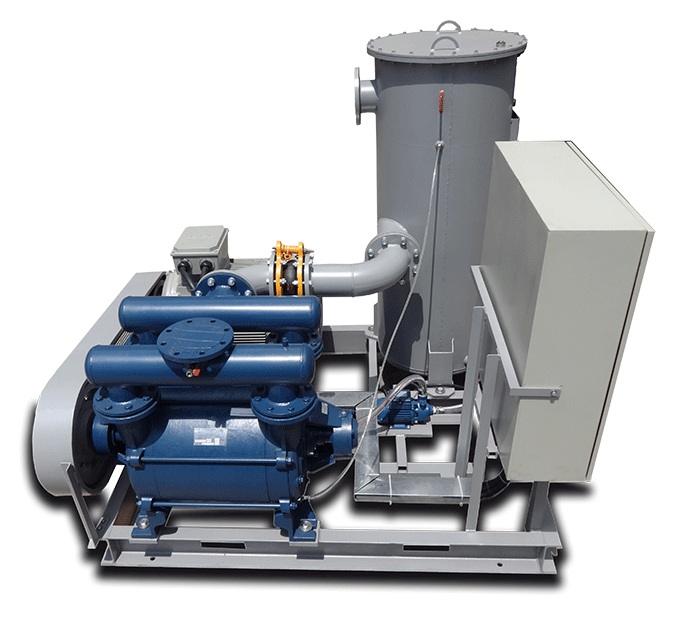

Oil-injected rotary screw compressor: This type of compressor injects a liquid into the compression chamber to cool and lubricate the compressor's moving parts, cool the air being compressed in the chamber, and help minimize leaks from returns into the chamber during discharge.

Here are the 4 simple steps you'll need to follow:

Remove the fill cap on the compressor.

Drain all the old oil inside the compressor using the drain plug.

Add oil through the compressor cover using a funnel.

Check the oil level through the oil sight glass or window. If you haven't added enough oil, add some more.

For instance, rotary screw compressors work best with ISO 32 or ISO 46 oils, but a reciprocating air compressor, on the other hand, will function better with SAE 30 or SAE 40 oils.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Compressor

Compressor