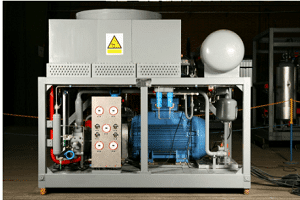

The compressor has the most important task in compressing low-pressure gas into high-pressure gas, which sends it to storage tanks or distributors with a pressure of about 250 bar. The compressor set is equipped with a relaxation chamber, which, when the compressor is off, the high pressure gas remaining in the compressor cylinders, in the pipes, and the coolant is discharged into it. The cooling system of the compressor set cools the temperature of the gas that has increased due to compression after each stage to increase the work efficiency. The set filters separate suspended particles and gas oil to a high percentage.

The tank trucks take CNG to customer's sites or consumption points, then CNG is taken from tank trucks with the pressure of 200-250 barg going through a Pressure Reducing Unit (PRU) system, pressure is reduced by two stages (Stage 1: pressure reduced to 60 barg, Stage: 2 pressure reduces to 2-7 barg) to supply ...

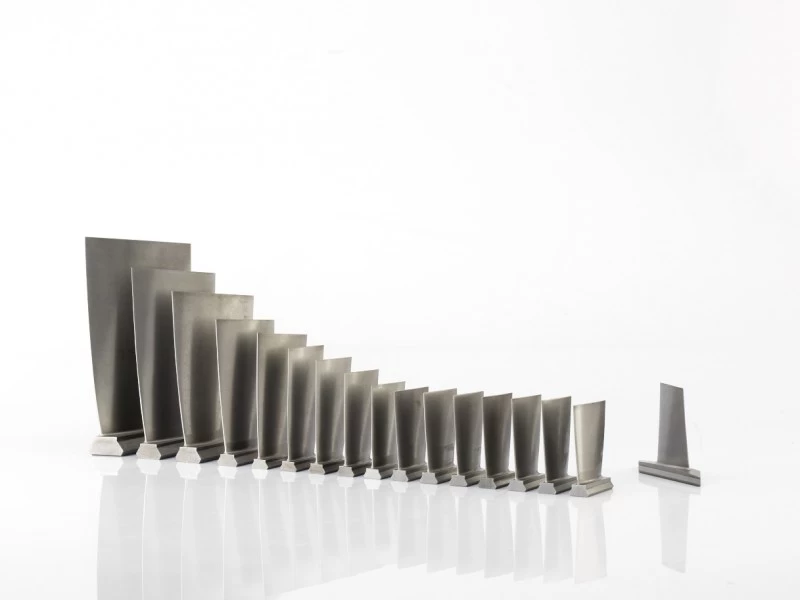

Available with capacity between 700 and 4500Nm3/h, the type D CNG compressor is ideal for medium and large sized CNG filling stations as well as CNG mother stations.

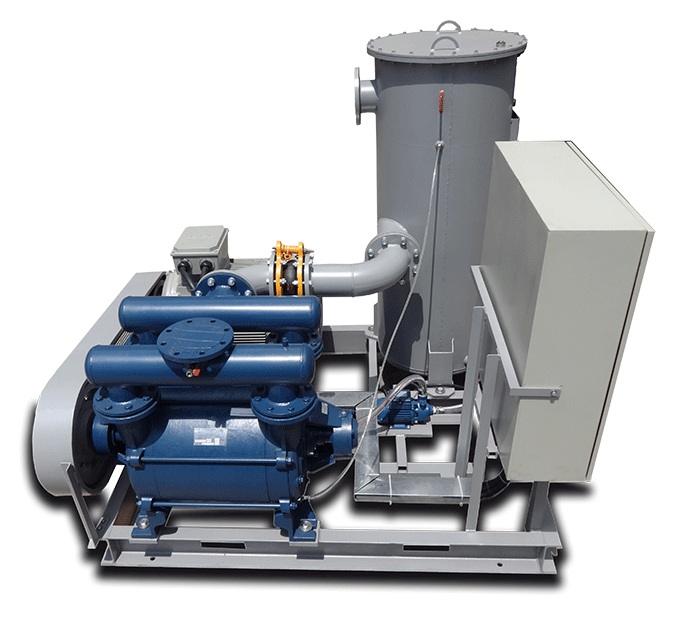

There are two main types of natural gas compressors used for industrial purposes — reciprocating and screw compressors. These two types of natural gas compressors work in different ways to compress the gas.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

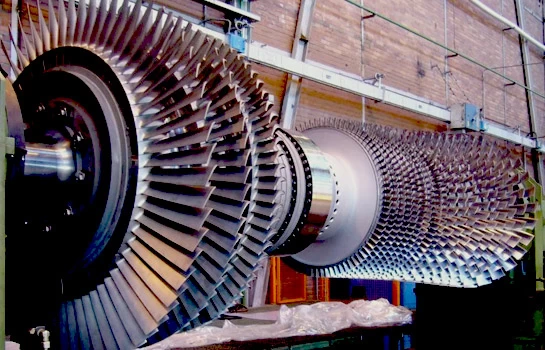

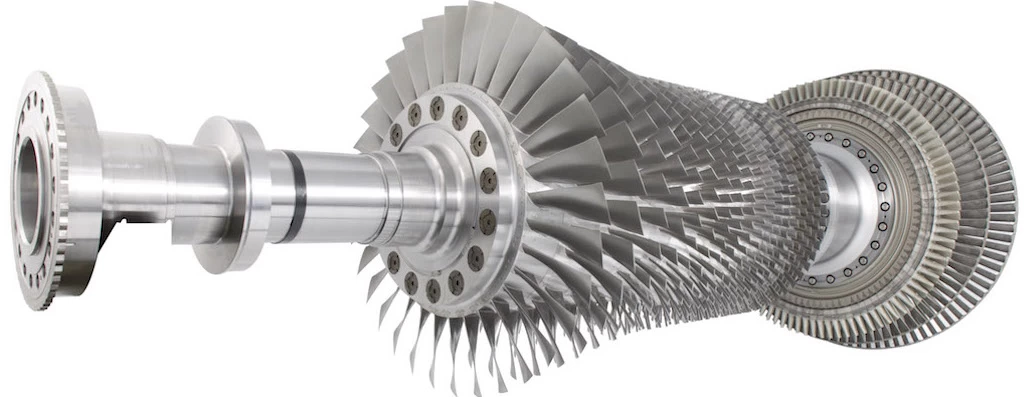

Compressor

Compressor