Food & Beverage Machinery

Food and beverage machinery encompasses a diverse range of equipment used in the production, processing, packaging, and preservation of food and beverages.

Here's an overview:

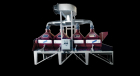

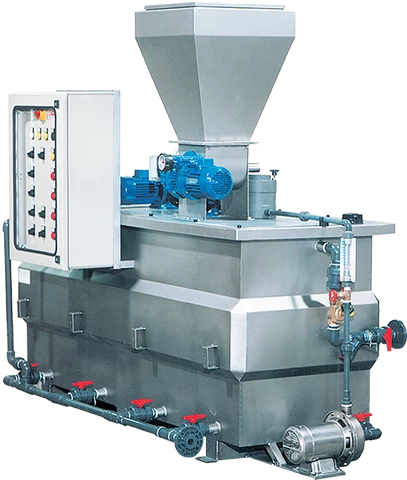

1. Processing Machinery: Processing machinery is used to transform raw ingredients into food and beverage products. This includes equipment such as mixers, blenders, grinders, slicers, and homogenizers, which are used to mix, grind, chop, and emulsify ingredients to create various food and beverage products.

2. Cooking and Heating Equipment: Cooking and heating equipment are used to cook, bake, roast, fry, or steam food products. This includes ovens, grills, fryers, steamers, and kettles, which apply heat to raw ingredients to cook or prepare them for further processing.

3. Refrigeration and Cooling Systems: Refrigeration and cooling systems are essential for preserving food and beverages and maintaining their freshness and quality. This includes refrigerators, freezers, chillers, and cooling tunnels, which provide controlled temperature environments for storing, chilling, or freezing food products.

4. Packaging Machinery: Packaging machinery is used to package food and beverage products for distribution and sale. This includes equipment such as filling machines, sealing machines, labeling machines, and wrapping machines, which package products into bottles, cans, pouches, cartons, or other containers.

5. Bottling and Canning Equipment: Bottling and canning equipment are specialized machinery used specifically for packaging beverages in bottles or cans. This includes bottle fillers, cappers, labelers, and can seamers, which automate the process of filling and sealing containers with beverages.

6. Sterilization and Pasteurization Equipment: Sterilization and pasteurization equipment are used to kill harmful microorganisms and extend the shelf life of food and beverage products. This includes equipment such as autoclaves, pasteurizers, and UV sterilizers, which apply heat, pressure, or radiation to eliminate pathogens and spoilage organisms.

7. Cleaning and Sanitation Systems: Cleaning and sanitation systems are essential for maintaining hygiene and food safety standards in food and beverage processing facilities. This includes equipment such as washers, sanitizers, and sterilizers, which clean and disinfect processing equipment, containers, and surfaces to prevent contamination.

8. Automation and Control Systems: Automation and control systems are increasingly used in food and beverage machinery to improve efficiency, consistency, and safety in production processes. This includes programmable logic controllers (PLCs), sensors, and robotics, which automate tasks such as ingredient handling, mixing, and packaging.

Overall, food and beverage machinery play a critical role in the efficient and hygienic production of a wide range of food and beverage products, ensuring quality, safety, and compliance with regulatory standards. Advances in technology continue to drive innovation in this sector, improving productivity, sustainability, and the overall quality of food and beverage processing operations.

Food and beverage machinery is used to process a wide variety of foods and beverages,

including but not limited to:

1. Beverages:

- Carbonated drinks (sodas)

- Bottled water

- Juices (fruit and vegetable)

- Alcoholic beverages (beer, wine, spirits)

- Dairy beverages (milk, yogurt drinks)

- Coffee and tea

2. Processed Foods:

- Baked goods (bread, cakes, cookies)

- Snack foods (chips, pretzels, popcorn)

- Breakfast cereals

- Confectionery (chocolates, candies, chewing gum)

- Dairy products (cheese, butter, ice cream)

- Frozen foods (frozen fruits and vegetables, ready meals)

3. Meat and Poultry Products:

- Fresh meat cuts

- Processed meats (sausages, deli meats)

- Poultry products (chicken, turkey)

- Seafood products (fish, shrimp, seafood mixes)

4. Fruits and Vegetables:

- Fresh fruits and vegetables

- Canned fruits and vegetables

- Frozen fruits and vegetables

- Dried fruits and vegetables

5. Condiments and Sauces:

- Ketchup, mustard, and other condiments

- Salad dressings and mayonnaise

- Pasta sauces and marinades

- Cooking oils and fats

6. Grains and Legumes:

- Rice and grains

- Pasta and noodles

- Bread and bakery products

- Legumes (beans, lentils, chickpeas)

7. Herbs, Spices, and Flavorings:

- Herbs and spices

- Flavor extracts and concentrates

- Seasonings and marinades

These are just some examples of the foods and beverages that are processed using food and beverage machinery. The specific types of machinery and equipment used vary depending on the nature of the product and the processing requirements.

Exporting food and beverage machinery involves selling and shipping equipment used in the production, processing, packaging, and preservation of food and beverages to international markets.

Here are some key aspects of food and beverage machinery exporting:

1. Market Analysis: Exporters need to conduct thorough market research to identify potential export markets for food and beverage machinery. This includes assessing demand, competition, regulatory requirements, and trade barriers in target countries.

2. Product Adaptation: Exporters may need to adapt their machinery to meet the specific needs and preferences of different markets. This could involve modifying equipment specifications, voltage requirements, or packaging to comply with local standards and regulations.

3. Export Compliance: Exporting food and beverage machinery requires compliance with export regulations and documentation requirements of both the exporting and importing countries. Exporters must ensure that their products meet applicable standards, certifications, and labeling requirements to gain market access and avoid customs issues.

4. Distribution Channels: Exporters can use various distribution channels to sell food and beverage machinery internationally. This includes working with local distributors, agents, or representatives in target markets, as well as participating in trade shows, exhibitions, and online marketplaces to showcase their products to potential buyers.

5. Logistics and Shipping: Exporters need to manage logistics and shipping arrangements to transport food and beverage machinery safely and efficiently to overseas destinations. This involves selecting reliable freight forwarders, arranging transportation, handling customs clearance, and ensuring proper packaging and documentation to minimize the risk of damage or delays during transit.

6. After-Sales Service: Providing after-sales service and support is crucial for maintaining customer satisfaction and loyalty in international markets. Exporters should offer technical assistance, spare parts, and maintenance services to ensure the smooth operation and longevity of their machinery for overseas customers.

7. Risk Management: Exporting food and beverage machinery involves certain risks, including political, economic, and legal risks associated with doing business in foreign markets. Exporters should assess and mitigate these risks through proper risk management strategies, such as insurance coverage, contractual agreements, and diversification of export markets.

8. Market Expansion: Exporters can leverage exporting food and beverage machinery as a strategic growth opportunity to expand their market reach and increase revenue. By tapping into new markets and establishing a global presence, exporters can diversify their customer base and reduce dependence on domestic sales.

In summary, exporting food and beverage machinery requires careful planning, market analysis, compliance with regulations, and effective distribution and logistics management to successfully penetrate international markets and capitalize on export opportunities.

Food and beverage machinery is used to process a wide variety of foods and beverages,

- Carbonated drinks (sodas)

- Bottled water

- Juices (fruit and vegetable)

- Alcoholic beverages (beer, wine, spirits)

- Dairy beverages (milk, yogurt drinks)

- Coffee and tea

2. Processed Foods:

- Baked goods (bread, cakes, cookies)

- Snack foods (chips, pretzels, popcorn)

- Breakfast cereals

- Confectionery (chocolates, candies, chewing gum)

- Dairy products (cheese, butter, ice cream)

- Frozen foods (frozen fruits and vegetables, ready meals)

3. Meat and Poultry Products:

- Fresh meat cuts

- Processed meats (sausages, deli meats)

- Poultry products (chicken, turkey)

- Seafood products (fish, shrimp, seafood mixes)

4. Fruits and Vegetables:

- Fresh fruits and vegetables

- Canned fruits and vegetables

- Frozen fruits and vegetables

- Dried fruits and vegetables

5. Condiments and Sauces:

- Ketchup, mustard, and other condiments

- Salad dressings and mayonnaise

- Pasta sauces and marinades

- Cooking oils and fats

6. Grains and Legumes:

- Rice and grains

- Pasta and noodles

- Bread and bakery products

- Legumes (beans, lentils, chickpeas)

7. Herbs, Spices, and Flavorings:

- Herbs and spices

- Flavor extracts and concentrates

- Seasonings and marinades

These are just some examples of the foods and beverages that are processed using food and beverage machinery. The specific types of machinery and equipment used vary depending on the nature of the product and the processing requirements.

FAQs

What are the key technological advancements driving innovation in food and beverage machinery?

Key technological advancements include automation, robotics, IoT connectivity, advanced sensors, and AI-driven systems, enhancing efficiency, precision, and quality control in food and beverage production processes.

How do exporters navigate regulatory compliance and documentation requirements when exporting food and beverage machinery to international markets?

Exporters navigate regulatory compliance by ensuring their machinery meets international standards, obtaining necessary certifications, and providing accurate documentation for customs clearance.

What factors should manufacturers consider when adapting food and beverage machinery for different global markets?

Manufacturers should consider voltage requirements, product specifications, packaging standards, and regulatory compliance when adapting machinery for different global markets.

How does the integration of automation and smart technology enhance the efficiency and productivity of food and beverage production processes?

Integration of automation and smart technology improves efficiency and productivity by streamlining processes, reducing manual labor, optimizing resource utilization, and enabling real-time monitoring and control in food and beverage production.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

.webp)