It has the shortest kneading time (8 to 12 minutes).

The possibility of adjusting the speed of the kneading process in two slow and fast modes

The rotation of the boiler in both clockwise and anti-clockwise directions

The possibility of connecting the city water inlet to increase the ease of kneading

The ability to prepare the dough for all kinds of large and semi-large breads, as well as the dough for a group of sweets

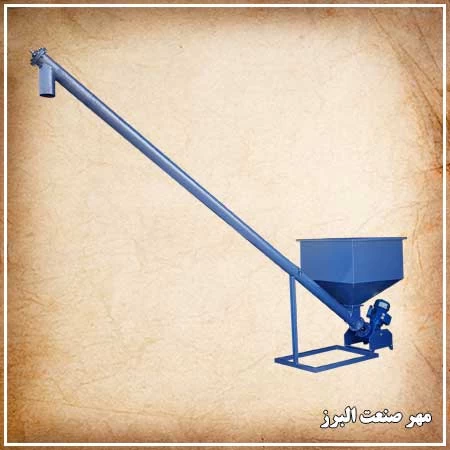

The ability to knead in small scales

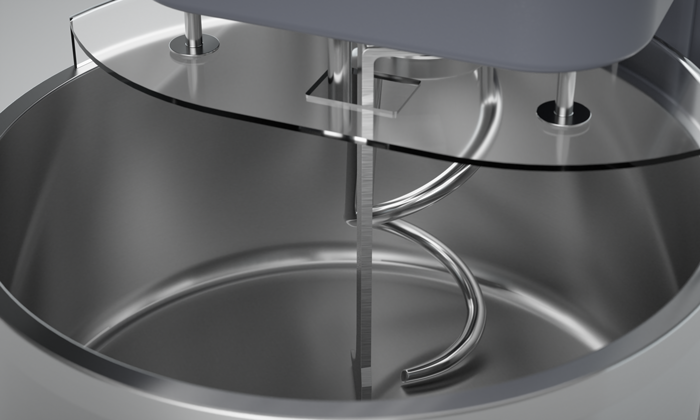

Optimum design of spiral horn for better dough uniformity

Making all the parts in contact with the dough, such as the spiral horn, blade, pot and lid, are made of steel with 304 alloy in accordance with international food industry standards.

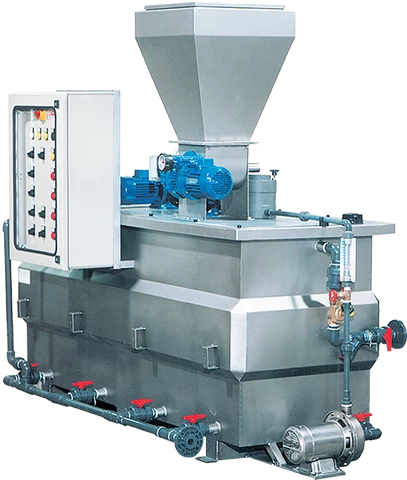

Using electronic and mechanical equipment from the most reliable European brands

Made of very durable chassis and body

It has a motion transmission system with a very low depreciation rate and low noise using cast wedges and accurate static balance.

The possibility of making the lid of the pot according to the customer's taste and needs, including steel doors, unbreakable polycarbonate talc doors, and special doors for more aeration of the dough (on request)

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Food & Beverage Machinery

Food & Beverage Machinery