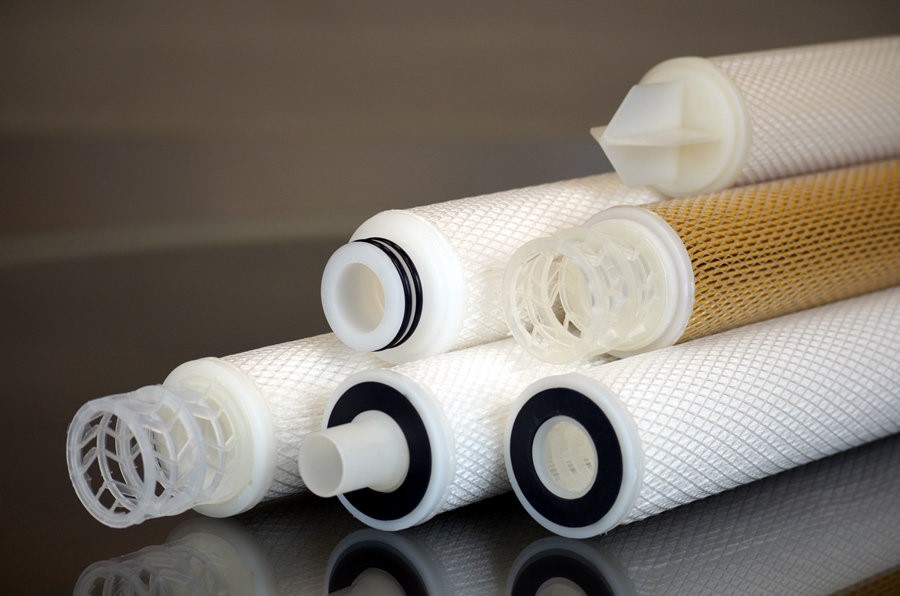

The liquid filters of Dillman Filter manufacturing company are designed and manufactured for the filtration of polluting materials as well as the separation of solid particles from the process fluid. Liquid filters are designed and manufactured in different types and their general classification is as follows:

oil filter

fuel filter

water filter

Amine filter

Glycol filter

Carbon filter (Canister Type)

Coalser oil filter

Coalser fuel filter

Coalser water filter

Therefore, according to the type of fluid and its temperature, different media can be provided.

Media Max. temp Services

Cotton 300°F Oils, solvents, process water, acids, etc

Fiberglass 750°F Acids, solvents, oils, etc. Used primarily for high temperature services

Nylon 350°F Concentrated alkalis and hydrocarbons

Acrylic/Orlon 300°F Recommended for strong acids

Polyester 250°F Similar to cotton and polypropylene, higher temperature resistance than polypropylene

Polypropylene 150°F Acids, process water, alkalis, and many other processes

Rayon 300°F Oil and many other processes

oil filter

Hydraulic and oil filters (Hydraulic & Lube Oil Filter) are designed and manufactured in order to separate solid particles and impurities from oil and lubricating fluid, according to the micron grade of the desired filter, the appropriate media is selected and used in filter production.

fuel filter

These filters prevent the entry of shaving particles and impurities, which are mainly due to cheap fuel or a contaminated tank, to the fuel pump and injector and possible damage to these parts. The optimal selection of this filter reduces impurities in the fuel and improves the combustion process and increases the power and life of the engine and related internal combustion parts.

Filter Material Stainless Mesh

Product Style Fuel Filters

Length 5.625 in (143 mm)

Outside Diameter 1.688 in (43 mm)

Package Contents 1 Fuel filter

Package Quantity 1

Weight 0.3 lb (0.1 kg)

Product Box Height 8.69 in (221 mm)

Product Box Length 2.5 in (64 mm)

Product Box Width 2.5 in (64 mm)

Filter Size 25 microns

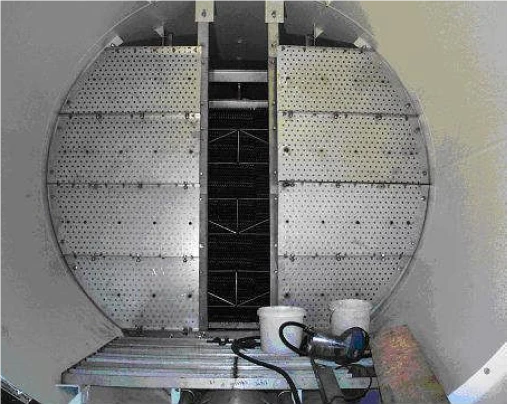

water filter

Water filters are used to separate solid particles from water and are designed and produced based on the filter's operating conditions, including temperature, pressure and degree of micron absorption. The pleated media, which gives the highest level of filtration inside the filter element, enables the separation of a wide range of particles with different micron sizes.

Amine filter

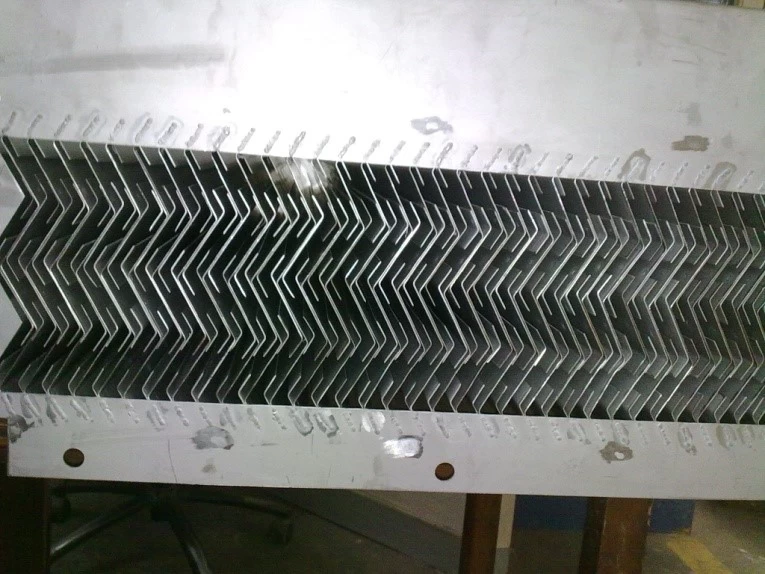

These filters, which are generally pleated in order to increase the level of filtration and service life, are designed and manufactured to separate organic and inorganic solid particles from the amine system in the gas sweetening plant. The type of media connection to the End Cap is such that bypass flow is prevented. Therefore, this type of filters have significant relative advantages compared to screw thread filters, which are generally made of ordinary cotton.

Glycol filter

These filters, which are generally pleated in order to increase the filtration level and service life, are designed and manufactured to separate organic and inorganic solid particles from the glycol system in the gas dehydration plant. The type of media connection to the End Cap is such that bypass flow is prevented. Therefore, this type of filters have significant relative advantages compared to screw thread filters, which are generally made of ordinary cotton. In terms of material and technical specifications, these filters are similar to cyclamine filters.

Carbon filter (Canister Type)

Dillman Filter manufacturing company has been able to design and provide different types of carbon filters (Canister Type) to consumers. This type of filter is mainly used for amine and glycol purification. The carbon grades used in this type of filters have a special granularity to have the highest amount of impurity absorption in the desired solvents with a long life.

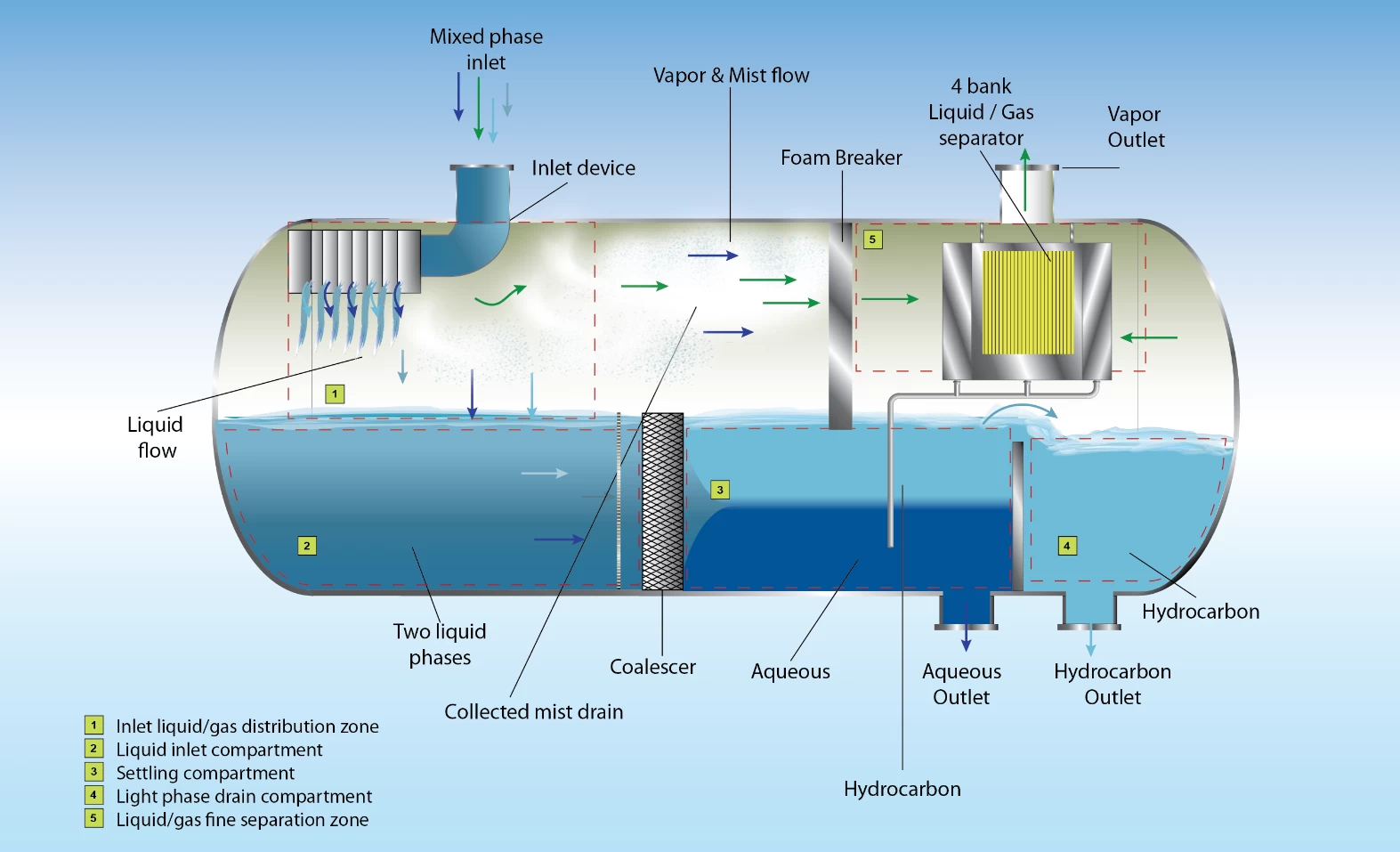

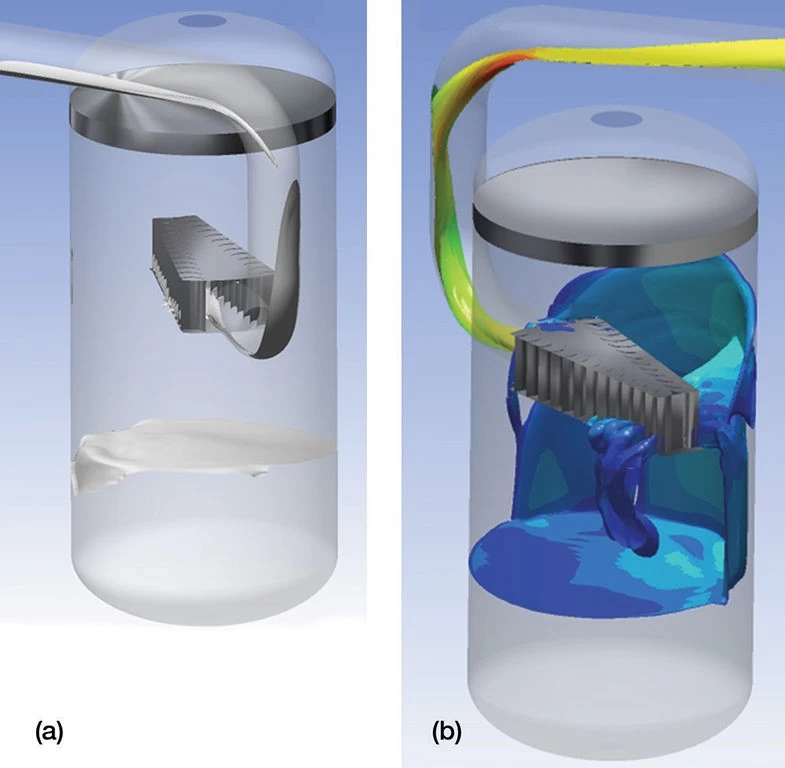

Coalser oil filter

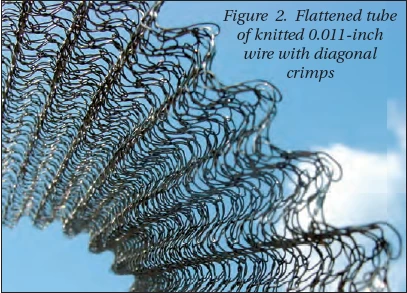

Oil coalser filters are used for coaling and separating water droplets from oil.

This company has been able to achieve a high level of cleanliness in oil by using the latest technology in the field of folding and using special media of microfiber glass (Pleated Microglass Filter Media). The amount of water in the oil can be reduced to 8ppm. Also, the amount of pollutant particles can be reduced to the clean level specified in the ISO 15/13/10 standard.

These media have different sizes of 1, 5, 10, 25 microns with β number equal to 1000 (separation efficiency 99.9) according to ISO 16889 standard.

Coalser fuel filter

Fuel coalescer filters are used to coalesce and separate water droplets from the fuel entering the engine. In terms of the type and grading of the media and the related tests, they are similar to the oil quailser filters described above.

Coalser water filter

Coalser water filters are used to separate solid particles and liquid droplets such as oil and hydrocarbon fluids from water. Usually, the solid particle separation filter or Prefilter is in one housing and the liquid-liquid separation filters, which generally differ from the two element filters with media with different surface properties, are designed and manufactured in separate housings. This will improve the performance and increase the life of the main housing filters (Coalescer & Separator Filter Cartridges). The technical specifications of Coalser and Separator filters are as follows. Prefilter media is generally paper and hydrophilic so that the separation process takes place properly.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial filters

Industrial filters