Air filters are designed in such a way that they have the ability to separate pollutants from the air stream with high quality. In these filters, proper and accurate filtration is performed through the passage of air fluid through the media. The air filters of the Dillman Filter manufacturing company are designed and manufactured in the following types depending on the type of use:

Cylindrical air filter

Conical air filter

Air Dryer Filter

Bag air filter (V-Bag)

Bag air filter

Panel air filter (Panel Filter)

Oil Mist air filter

Cylindrical air filter

Cylindrical air filters are used to separate solid particles and dust from the air in the inlet chamber to the turbine.

According to the type of media, these filters can be provided with different filtration efficiencies based on the EN779 standard and according to the table below. The newer edition of this EN779: 2012 standard forces manufacturers to provide a more suitable filter. In this standard, for the Fine Filter group, in addition to the average efficiency, another parameter called the minimum efficiency is also specified. This parameter is the minimum efficiency of particle separation with a diameter of 0.4 microns for the complete filter, as well as testing three samples of the original media with a minimum media surface of 600cm² after soaking in isopropanol (IPA) solution. This parameter is not measured for the Medium group, so the name of their group was changed in this standard to show that their test method is different from the Fine Filter group.

Classification of air filters

Group Class Final pressure

drop (test)

Pa Average

arrestance (Am)

of synthetic dust

% Average

efficiency (Em)

for 0.4 μm

particles

% Minimum

efficiency

for 0.4 μm particles

%

Coarse G1 250 50≤Am<65 – –

G2 250 65≤Am<80 – –

G3 250 80≤Am<90 – –

G4 250 90≤Am – –

Medium M5 450 – 40≤Em<60 –

M6 450 – 60≤Em<80 –

Fine F7 450 – 80≤Em<90 35

F8 450 – 90≤Em<95 55

F9 450 – 95≤Em 70

The Minimum efficiency parameter is the lowest efficiency among the Initial Efficiency and Discharged Efficiency parameters and in fact during the entire test.

All types of cylindrical filters used in the inlet air chamber of Typhoon, V94.2, Ansaldo, Siemens, etc. turbines are designed and produced by this company.

Conical air filter

Conical air filters are used in pairs along with cylindrical air filters (Conical/Cylindrical pairs) in order to separate solid particles and dust from the air in the inlet chamber to the turbine.

Air Dryer Filter

Air Dryer air filters are used to separate solid particles, oil droplets and moisture in the compressed air entering the absorbent bed. The design of these filters is in such a way that they are fully consistent with the compressed air packages provided by the world's most reliable manufacturers such as Ingersoll Rand & Atlas Copco in the form of Prefilter & AfterFilter.

The use of media with high separation efficiency (Borosilicate Glass Fiber Layer) enables the minimum degree of micron absorption in this type of filters up to 0.01 micron in diameter.

Bag air filter (V-Bag)

V-Bag air filters are used to separate solid particles and dust from the air in the HVAC system.

These filters can be provided in this company with different filtration efficiencies and initial and medium low pressure drop and MERV 11, MERV 13, MERV 14, MERV 9 categories in accordance with the ASHRAE 52.2 standard.

Bag air filter

Bag air filters are used to separate solid particles and dust from air and particles from hydraulic fluid and lubricants. And according to the functional conditions and fluid temperature, filters can be provided with PE, PTFE, PPS, PP media up to one micron absorption degree. At high temperature and where oil absorption on the surface of the media is not desirable, polyester is recommended. These media all have a valid Test Certificate in which the separation efficiency and the amount of particle absorption (Dirt Holding Capabilities) are specified. In such a way that the separation efficiency is the same for both PE and PP media.

Panel air filter (Panel Filter)

Panel air filters are used to separate solid particles and dust from the air.

These filters can be provided with a variety of frames and media with different filtration efficiency according to ASHRAE 52.2 standard in the HVAC system.

Also, this company has the ability to produce different types of these filters with filtration efficiency from G4 to F9 according to EN 779 standard.

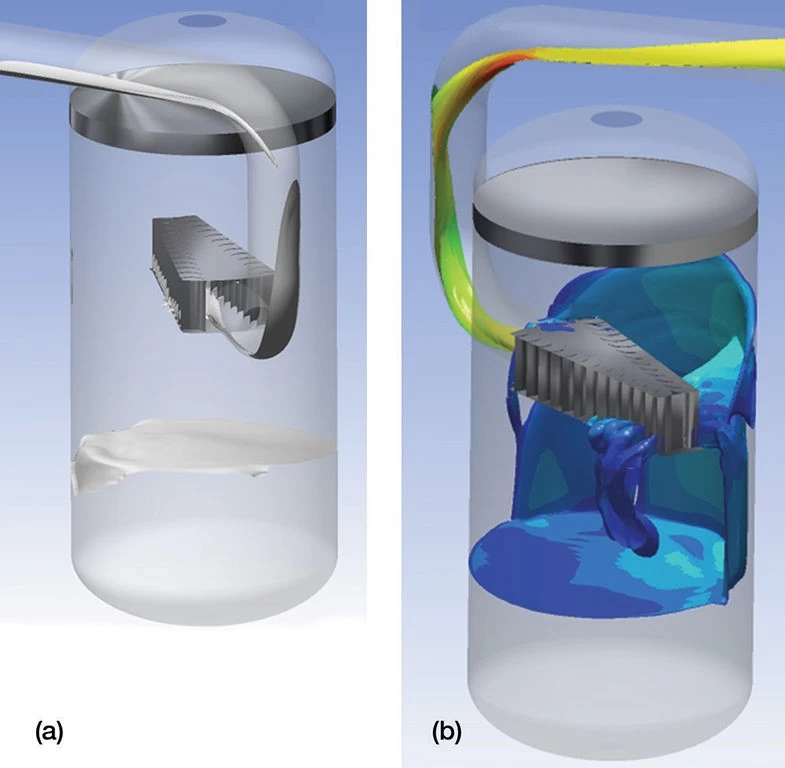

Oil Mist air filter

Oil Mist Eliminator filters are used to separate the oil droplets in the exhaust air from the Vacuum Pump. Therefore, designing a suitable filter element for quality oil recovery, maintaining the health of employees and environmental regulations such as OSHA & EPA. It is very important.

The separation efficiency of these filters is generally 99.9% (β, 1000) for droplets with a diameter of 10 microns and larger, such that the amount of oil remaining in the air outlet stream after the filtration process is 0.1 mg per cubic meter of air.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial filters

Industrial filters