Description

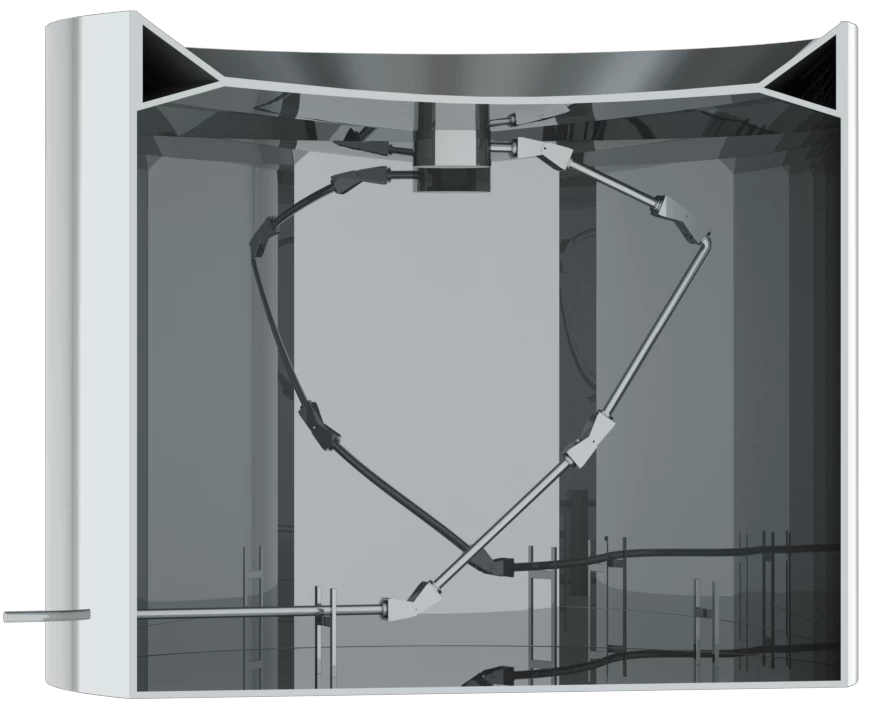

Perforated flange with a steel core is a product of Takab Estas Damavand company, which is produced with polyethylene (PE) raw material. This product is produced and marketed with black masterbatch from size 63 to 400 mm, at pressures of 6 to 25 atmospheres based on the national standard of Iran INSO14427-3 and international standards such as DIN2501 and ISO4427. As you know, the polyethylene cover is on the metal rim, which increases the lifetime of the rim according to the lifetime of polyethylene and is equal to 50 years.

Advantages of using perforated flange with steel core in the project:

It increases the life of the project.

Non-corrosiveness of the rim even in very corrosive environments such as acids, sea water, etc.

Use of shorter screw compared to metal flange and rim

Reasonable price compared to flange and metal rim

Uniform stress distribution on all surfaces

How to install this connection:

This connection can be installed through the following welds:

Electrofusion welding: with a high reliability factor

Butt fusion welding: butt-to-butt

Note: If you are not familiar with electrofusion welding and butt fusion, we suggest you read the article on the difference between electrofusion welding and butt fusion . You can also read the article Everything you need to know about electrofusion welding for more information .

"Note that if you intend to carry out the welding process in the project, you can contact the consulting engineers of Takab Istas Damavand Company to receive the necessary guidance and complete the project successfully."

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Other Construction & Real Estate

Other Construction & Real Estate