Security & Protection

The intersection of security and production is crucial in various industries to ensure the safety of processes, assets, and personnel. Here are a few key aspects:

1. Physical Security: Implementing measures to secure production facilities, warehouses, and critical infrastructure to protect against unauthorized access, theft, and vandalism.

2. Personnel Safety: Integrating safety protocols and equipment to minimize the risk of accidents and injuries during production processes.

3. Data Security: Safeguarding production-related data, including intellectual property, design specifications, and sensitive information, to prevent unauthorized access or industrial espionage.

4. Supply Chain Security: Ensuring the security of the supply chain to prevent disruptions, theft, or tampering of raw materials and finished goods during transportation or storage.

5. Cybersecurity: Protecting production systems and networks from cyber threats to prevent unauthorized access, data breaches, and potential disruptions in manufacturing processes.

6. Quality Control: Implementing security measures to maintain the quality and integrity of the production process, ensuring that products meet regulatory standards and customer expectations.

Balancing security and production efficiency is essential to maintain a smooth and reliable manufacturing process. It requires a holistic approach that considers physical, digital, and personnel aspects of security while minimizing disruptions to production workflows.

A casting service typically refers to a service that provides the manufacturing process of casting, where molten material, often metal or plastic, is poured into a mold to create a specific shape. Casting is a widely used manufacturing method for producing complex parts and components.

There are different types of casting processes, including:

1. Metal Casting: Involves pouring molten metal into a mold to create metal parts. This can include processes like sand casting, investment casting, and die casting.

2. Plastic Casting: Similar to metal casting but involves using molten plastic or resin to create plastic parts.

Casting services are commonly utilized in various industries, including automotive, aerospace, construction, and more. They provide a cost-effective way to produce intricate and large-scale components.

A forging service involves the process of forging, which is a manufacturing method where metal is shaped through the application of localized compressive forces. This process is typically performed at elevated temperatures, although some types of forging can be done at room temperature. Forging is commonly used to produce strong and durable metal components.

There are various types of forging processes, including:

1. Open Die Forging: Involves deforming a piece of metal between multiple dies, where the dies do not enclose the material entirely.

2. Closed Die Forging: The metal is placed within a set of dies that contain a cavity corresponding to the shape of the final product.

3. Impression Die Forging: Similar to closed die forging, but the dies contain impressions on their surfaces that impart specific shapes to the metal.

Forging services are often employed in industries such as automotive, aerospace, and oil and gas, where strong and precisely shaped metal components are

Safety equipment plays a crucial role in protecting individuals from potential hazards in various environments. Common types of safety equipment include:

1. Personal Protective Equipment (PPE):

- Hard Hats: Protect the head from falling objects.

- Safety Glasses/Goggles: Shield the eyes from debris, chemicals, or other hazards.

- Ear Protection: Earplugs or earmuffs to reduce noise exposure.

- Gloves: Different types for hand protection against cuts, chemicals, or abrasions.

- Respirators/Masks: Filter airborne particles or protect against inhalation of hazardous substances.

2. Foot Protection:

- Steel-Toed Boots: Protect feet from falling objects or compression.

3. Fall Protection:

- Harnesses: Prevent falls from heights, commonly used in construction.

4. High Visibility Clothing:

- Reflective Vests: Enhance visibility in low-light conditions, often used in construction or traffic management.

5. First Aid Kits:

- Contain essential supplies for providing immediate medical assistance in case of injuries.

6. Safety Signs and Labels:

- Clearly communicate hazards and safety instructions in the workplace.

7. Fire Safety Equipment:

- Fire Extinguishers: Used to control or extinguish fires.

- Fire Blankets: Smother small fires or wrap around a person in case of a clothing fire.

8. Emergency Eyewash and Shower Stations:

- Provide immediate flushing of eyes or body in case of exposure to chemicals.

9. Head Protection Accessories:

- Bump Caps: Offer lightweight protection against minor head bumps

10. Protective Clothing:

- Coveralls: Full-body protection against chemicals or contaminants.

The specific safety equipment needed depends on the nature of the work and potential hazards in a given environment. Employers should assess risks and provide the appropriate safety equipment to ensure the well-being of workers.

Fire safety equipment is essential for preventing, detecting, and responding to fires. Common fire safety equipment includes:

1. Fire Extinguishers:

- Portable devices that discharge firefighting agents to extinguish or control small fires. Different types are available for various fire classes (A, B, C, D, or a combination).

2. Fire Sprinkler Systems:

- Automatic systems that release water or other fire-suppressing agents when a predetermined temperature is reached.

3. Fire Alarms:

- Detection systems that sound an alarm in the presence of smoke, heat, or flames to alert occupants and initiate emergency response.

4. Fire Blankets:

- Flame-resistant blankets used to smother small fires or wrap around a person to extinguish clothing fires.

5. Emergency Exit Signs:

- Clearly marked signs indicating escape routes and exits to facilitate safe evacuation.

6. Emergency Lighting:

- Battery-powered lighting that activates during power failures, aiding evacuation in low-light conditions.

7. Smoke Detectors:

- Devices that detect the presence of smoke and emit alarms to warn occupants of a potential fire.

8. Fire Hose Reels:

- Reels containing fire hoses for manual firefighting efforts.

9. Fire Doors:

- Doors designed to resist the spread of fire and smoke, providing a barrier to protect occupants and property.

10. Fire Hydrants:

- Outdoor water supply points for firefighting purposes, often connected to municipal water systems.

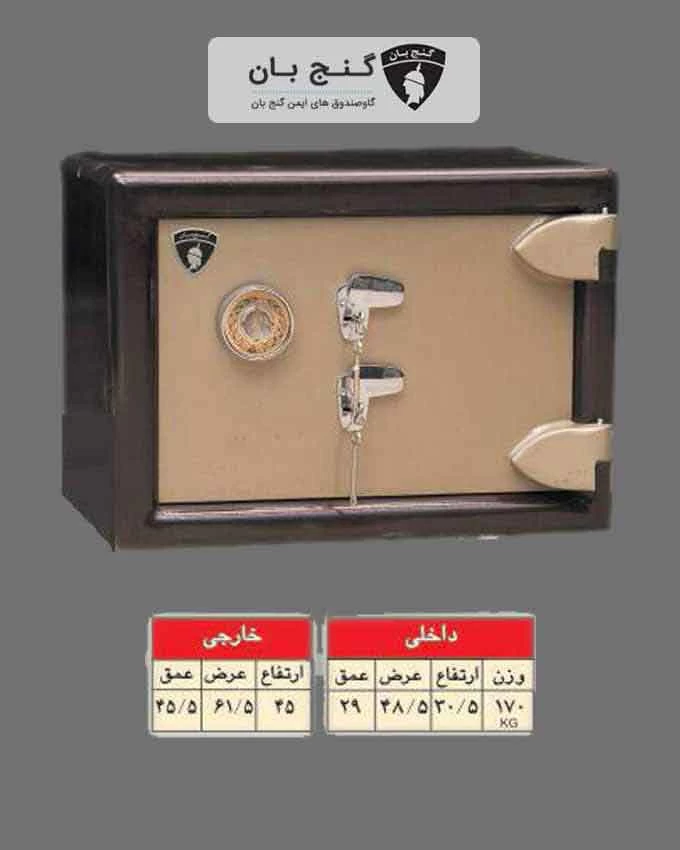

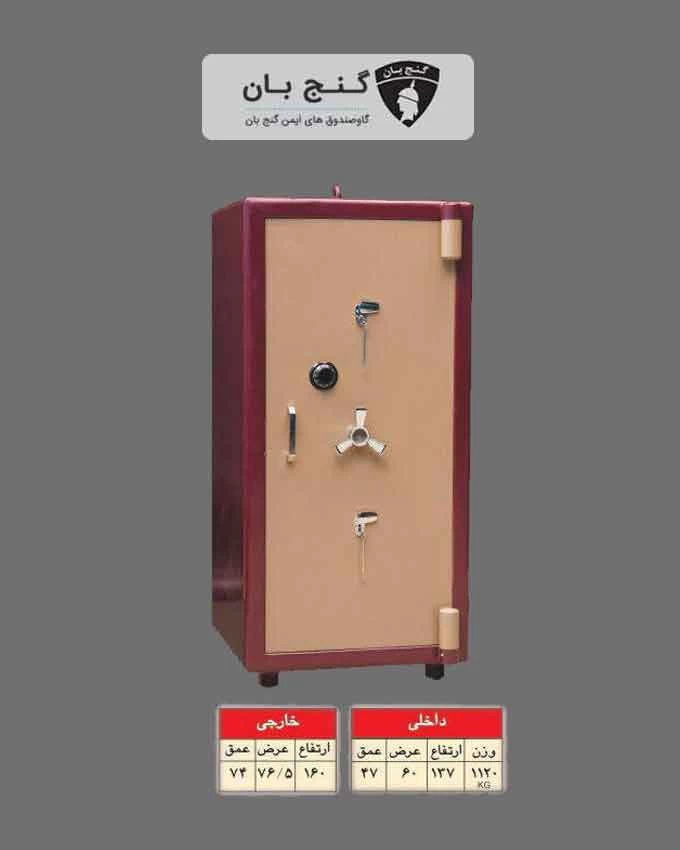

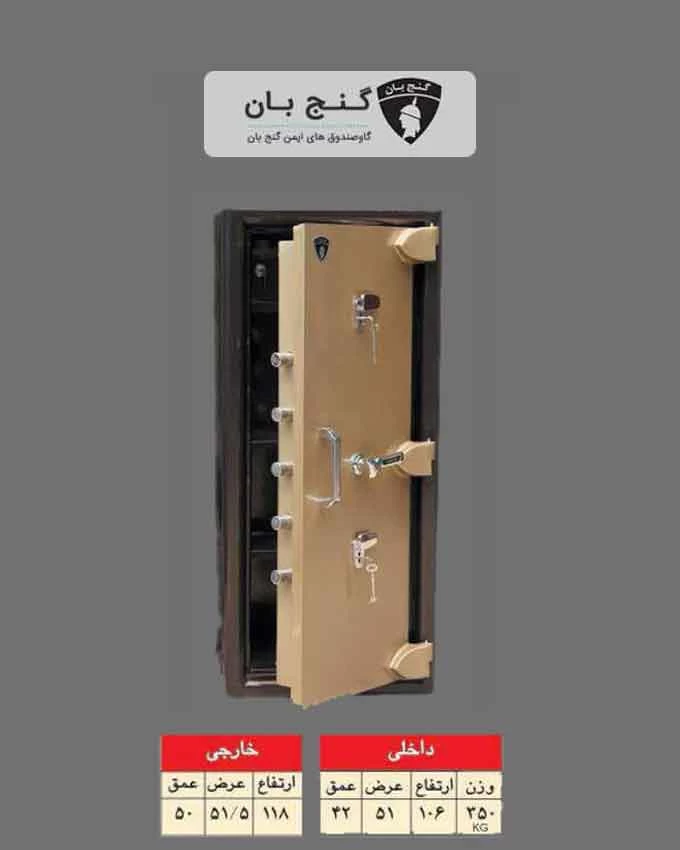

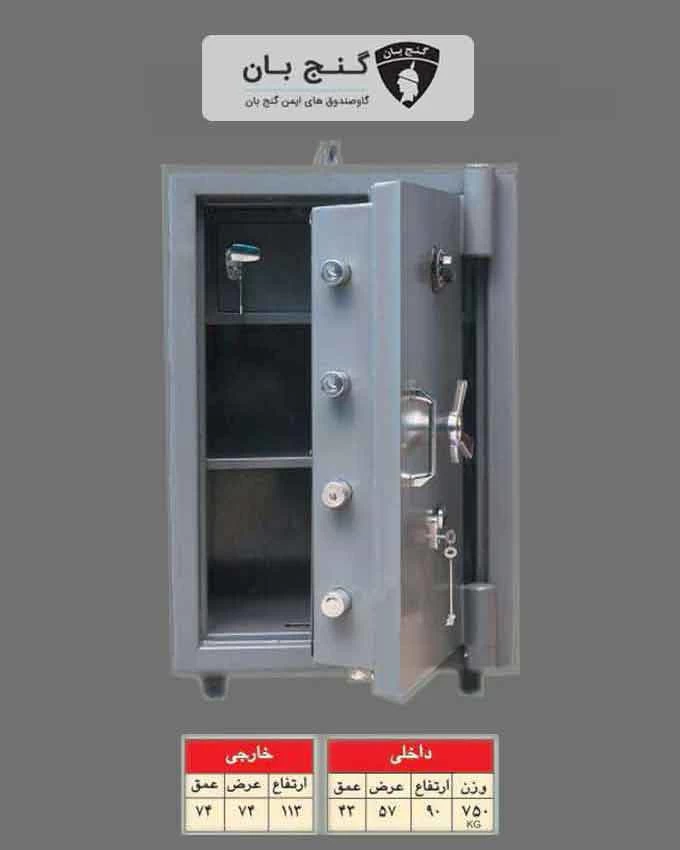

11. Fireproof Cabinets:

- Cabinets designed to protect important documents and valuables from fire damage.

It's crucial to regularly inspect, maintain, and test fire safety equipment to ensure its proper functionality. Additionally, training occupants on proper fire safety procedures and evacuation routes is essential for a comprehensive fire safety plan.

2. Personnel Safety: Integrating safety protocols and equipment to minimize the risk of accidents and injuries during production processes.

3. Data Security: Safeguarding production-related data, including intellectual property, design specifications, and sensitive information, to prevent unauthorized access or industrial espionage.

4. Supply Chain Security: Ensuring the security of the supply chain to prevent disruptions, theft, or tampering of raw materials and finished goods during transportation or storage.

5. Cybersecurity: Protecting production systems and networks from cyber threats to prevent unauthorized access, data breaches, and potential disruptions in manufacturing processes.

6. Quality Control: Implementing security measures to maintain the quality and integrity of the production process, ensuring that products meet regulatory standards and customer expectations.

A casting service typically refers to a service that provides the manufacturing process of casting, where molten material, often metal or plastic, is poured into a mold to create a specific shape. Casting is a widely used manufacturing method for producing complex parts and components.

There are different types of casting processes, including:

1. Metal Casting: Involves pouring molten metal into a mold to create metal parts. This can include processes like sand casting, investment casting, and die casting.

Casting services are commonly utilized in various industries, including automotive, aerospace, construction, and more. They provide a cost-effective way to produce intricate and large-scale components.

1. Open Die Forging: Involves deforming a piece of metal between multiple dies, where the dies do not enclose the material entirely.

2. Closed Die Forging: The metal is placed within a set of dies that contain a cavity corresponding to the shape of the final product.

3. Impression Die Forging: Similar to closed die forging, but the dies contain impressions on their surfaces that impart specific shapes to the metal.

Forging services are often employed in industries such as automotive, aerospace, and oil and gas, where strong and precisely shaped metal components are

Safety equipment plays a crucial role in protecting individuals from potential hazards in various environments. Common types of safety equipment include:

- Hard Hats: Protect the head from falling objects.

- Safety Glasses/Goggles: Shield the eyes from debris, chemicals, or other hazards.

- Ear Protection: Earplugs or earmuffs to reduce noise exposure.

- Gloves: Different types for hand protection against cuts, chemicals, or abrasions.

- Respirators/Masks: Filter airborne particles or protect against inhalation of hazardous substances.

- Steel-Toed Boots: Protect feet from falling objects or compression.

3. Fall Protection:

- Harnesses: Prevent falls from heights, commonly used in construction.

4. High Visibility Clothing:

- Reflective Vests: Enhance visibility in low-light conditions, often used in construction or traffic management.

5. First Aid Kits:

- Contain essential supplies for providing immediate medical assistance in case of injuries.

6. Safety Signs and Labels:

- Clearly communicate hazards and safety instructions in the workplace.

7. Fire Safety Equipment:

- Fire Extinguishers: Used to control or extinguish fires.

- Fire Blankets: Smother small fires or wrap around a person in case of a clothing fire.

8. Emergency Eyewash and Shower Stations:

- Provide immediate flushing of eyes or body in case of exposure to chemicals.

9. Head Protection Accessories:

- Bump Caps: Offer lightweight protection against minor head bumps

- Coveralls: Full-body protection against chemicals or contaminants.

The specific safety equipment needed depends on the nature of the work and potential hazards in a given environment. Employers should assess risks and provide the appropriate safety equipment to ensure the well-being of workers.

Fire safety equipment is essential for preventing, detecting, and responding to fires. Common fire safety equipment includes:

1. Fire Extinguishers:

- Portable devices that discharge firefighting agents to extinguish or control small fires. Different types are available for various fire classes (A, B, C, D, or a combination).

2. Fire Sprinkler Systems:

- Automatic systems that release water or other fire-suppressing agents when a predetermined temperature is reached.

3. Fire Alarms:

- Detection systems that sound an alarm in the presence of smoke, heat, or flames to alert occupants and initiate emergency response.

4. Fire Blankets:

- Flame-resistant blankets used to smother small fires or wrap around a person to extinguish clothing fires.

5. Emergency Exit Signs:

- Clearly marked signs indicating escape routes and exits to facilitate safe evacuation.

6. Emergency Lighting:

- Battery-powered lighting that activates during power failures, aiding evacuation in low-light conditions.

7. Smoke Detectors:

- Devices that detect the presence of smoke and emit alarms to warn occupants of a potential fire.

8. Fire Hose Reels:

- Reels containing fire hoses for manual firefighting efforts.

9. Fire Doors:

- Doors designed to resist the spread of fire and smoke, providing a barrier to protect occupants and property.

10. Fire Hydrants:

- Outdoor water supply points for firefighting purposes, often connected to municipal water systems.

11. Fireproof Cabinets:

- Cabinets designed to protect important documents and valuables from fire damage.

FAQs

What is casting service?

A casting service typically refers to a service that provides the manufacturing process of casting, where molten material, often metal or plastic, is poured into a mold to create a specific shape

What does forging services include?

Forging services include the forging process, which is a manufacturing method in which metal is formed through the application of localized compressive forces.

Is fire safety equipment necessary?

Fire safety equipment is essential for preventing, detecting, and responding to fires.

What does safety equipment depend on?

The specific safety equipment needed depends on the nature of the work and potential hazards in a given environment.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)