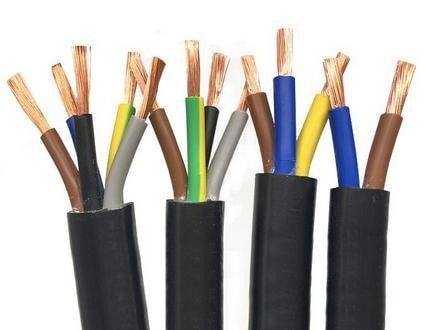

Wires and cables in the electrical industry are produced from two general types of hard conductors or flexible conductors. Each of these two wires have different values and functions in their place. Flexible conductor wire is widely used in the electrical appliance manufacturing industry. You can see these wires in abundance around you. Wires with conductive conductors are produced with different voltages depending on the expectations from it, and naturally they have different applications.

Sprayed wires and cables can be used in various sectors of the electrical industry. The main feature of these wires is their high flexibility. When you want to use the wire and cable where there is a need to bend them, or when the cable is used in a device that is accompanied by movement and displacement, you need a cable and wire spreader. As mentioned, there are different types of wire that you can use in your project, depending on the type of application.

The structure of the sprinkler wire

Spray wire, which we also know by names such as flexible wire, often includes a copper conductor. Copper is one of the best conductors of current that is used to transfer current. Today, aluminum conductors are also used to produce power wires and cables; But copper is still the first choice of industrialists for the production of spark plugs. The copper used in these wires is annealed with high purity.

The structure and application of wire spraying

There are fixed and specific national and international standards for the conductors in wire mesh, which manufacturers must manufacture their products based on. ISRI 3084 and IEC 60228 are two national and international standards for wiring.

To cover these wires, resistant and flexible PVC polymer is used to be compatible with the type of operation of flexible wires. The insulation on the sprinkler wires has normal resistance against destructive factors; Therefore, they are often used in indoor places or in household electrical appliances.

Types of wire feeders based on rated voltage

Types of wires

Al-Ashaan wires can be divided into two categories based on the nominal voltage, and we will examine each of them below.

300 to 500 V nominal voltage

This type of sprinkler wires, which have a lower voltage than their other counterparts, are used for installation inside hose pipes , under and on plastering of buildings, and also for installation inside pipes.

Wire stripper with a rated voltage of 450 to 750 volts

This type of wires can also be used under and over plastering or for installation inside pipes. The most common use of this type of conductor wire is in household electrical appliances, in humid and dry environments, and in lighting systems.

Suggested article: What is shielded cable + introduction of shielded cable types

The conductor standards chosen for these wires are of great importance in their correct operation. This is the reason why the conditions of price and purchase of the wire produced by different companies are different.

Wire spraying has very wide uses in the electrical industry. This wire is made with flexible copper conductor and is suitable for use in dry spaces (very low humidity) or inside electrical devices.

last word

For consultation and purchase of Abhar wires and cables, contact the numbers on the site.

With / PVC

Conductor material and class: Class 5 annealed copper (Afshan)

Insulation material: PVC type C

Insulation coloring: according to customer request

Application :

These types of wires are used for fixed installation as connection wires in underground ducts, machines and control panels that need a lot of flexibility.

The three wires used to carry electricity from one place to another are:

Live wire (L)

Neutral wire (N)

Earth wire (E)

To determine what gauge wire you need, consider the carrying capacity and the amount of current the wire needs to conduct (measured in amperage or amps). Wire gauge is directly related to how many amps you need to run through it. The distance you need the wire to go can also impact the gauge of wire you need.

The main electrical wire and cable types include single conductor wire ( single strand wire), multi-conductor wire ( stranded wire ) , single , two and three-core cables, and armored wire ( armored cable ).

So, USE cables stand for underground service entrance cables. Again, for cables to be used underground, they must be able withstand pressure and other elements.

In most cases, 3 core cables tend to be an electrical wire that has three separate copper conductors, each within its protective jacket, sheathed in an external jack or protective sheathe. The case with a 3 core and earth cable is different because there is a fourth conductor inserted during the manufacturing process.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Wires, Cables & Cable Assemblies

Wires, Cables & Cable Assemblies