stone industry

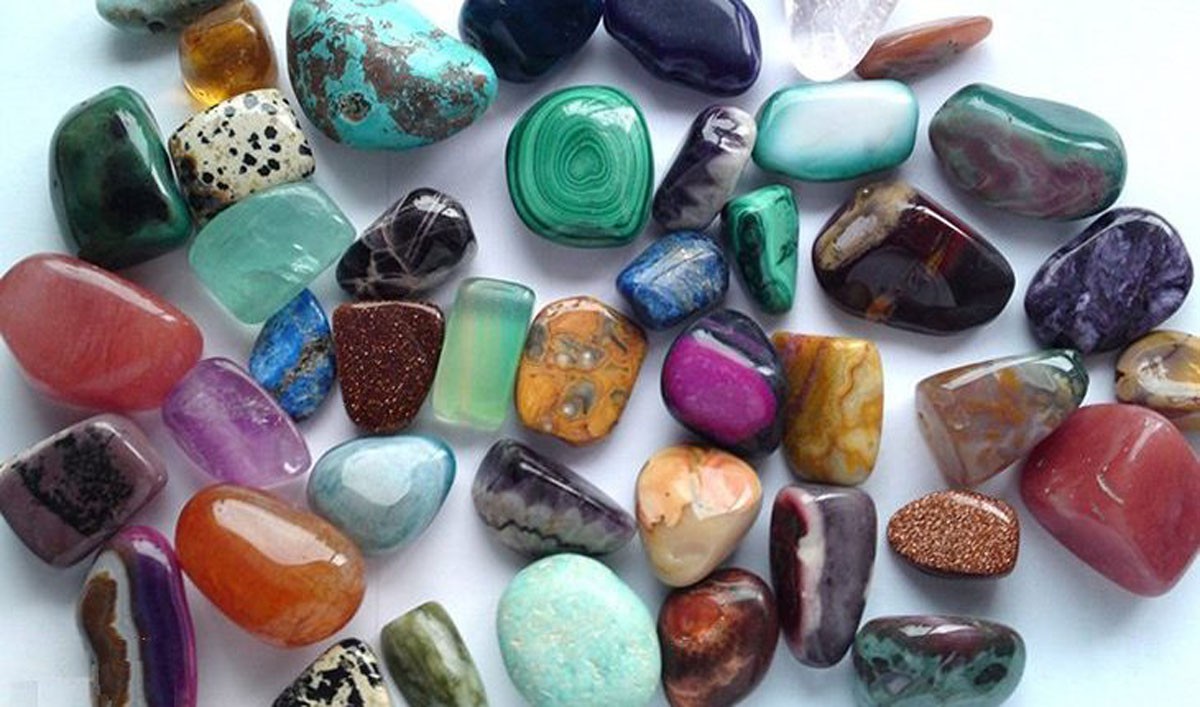

The stone industry refers to the sector involved in the extraction, processing, manufacturing, and distribution of natural stone products. Natural stone, including granite, marble, limestone, sandstone, slate, and travertine, is widely used in various applications such as construction, architecture, interior design, landscaping, monuments, and sculptures.

Here are some key aspects of the stone industry:

1. Extraction: Natural stone is typically quarried from mines or open-pit mines where large blocks of stone are extracted from the earth's crust. This process involves drilling, blasting, cutting, and transporting the stone blocks to processing facilities.

2. Processing: Once extracted, the stone blocks undergo various processing steps to create finished products. This may include cutting, sawing, polishing, grinding, and shaping the stone to meet specific size, shape, and finish requirements.

3. Manufacturing: Processed stone is used to manufacture a wide range of products such as slabs, tiles, countertops, flooring, cladding, pavers, monuments, and sculptures. These products are produced in factories or workshops using advanced machinery and techniques.

4. Distribution: Finished stone products are distributed to various markets and industries through wholesalers, distributors, retailers, and exporters. The distribution network may involve local, national, or international trade depending on the demand and market conditions.

5. Applications: Natural stone is used in a diverse range of applications across different sectors. In the construction industry, it is commonly used for building facades, flooring, countertops, walls, and decorative elements. In the architectural and interior design fields, natural stone adds elegance and sophistication to residential, commercial, and public spaces. Stone is also used in landscaping projects, urban design, monuments, memorials, and art sculptures.

5. Applications: Natural stone is used in a diverse range of applications across different sectors. In the construction industry, it is commonly used for building facades, flooring, countertops, walls, and decorative elements. In the architectural and interior design fields, natural stone adds elegance and sophistication to residential, commercial, and public spaces. Stone is also used in landscaping projects, urban design, monuments, memorials, and art sculptures.

6. Sustainability: The stone industry is increasingly focused on sustainable practices to minimize environmental impact and promote responsible sourcing. This includes initiatives to reduce waste, optimize resource use, implement eco-friendly production processes, and support ethical labor practices.

7. Innovation: Advances in technology and manufacturing techniques have led to innovations in the stone industry, allowing for greater customization, precision, and efficiency in product design and fabrication. Digital fabrication technologies, such as CNC machines and waterjet cutting, have revolutionized the way natural stone is processed and shaped.

Overall, the stone industry plays a vital role in the global economy and in shaping the built environment. Natural stone products are valued for their durability, beauty, and timeless appeal, making them a preferred choice for various architectural and design projects around the world.

_1710355199.jpg)

The extraction of natural stone involves several steps, from locating suitable deposits to processing the extracted stone into usable products. Here's an overview of the extraction process:

1. Exploration and Site Selection: The process begins with geological surveys and exploration to identify areas with suitable deposits of natural stone. Geologists and mining engineers assess factors such as stone quality, quantity, accessibility, and environmental considerations to determine the viability of a quarry site.

2. Permitting and Land Acquisition: Once a suitable site is identified, the necessary permits and licenses must be obtained from local authorities and regulatory agencies. This may involve environmental impact assessments, land use planning, and compliance with zoning regulations.

3. Drilling and Blasting: The extraction process typically starts with drilling holes into the earth's surface using specialized equipment. Explosive charges are then inserted into the drill holes and detonated to break apart the rock mass into manageable-sized blocks.

4. Excavation and Transportation: After blasting, excavators and front-end loaders are used to remove the broken rock and transport it to a processing facility or temporary stockpile. Large blocks of stone are often transported using heavy machinery or trucks equipped with cranes.

5. Primary Processing: At the processing facility, the extracted stone blocks undergo primary processing to remove excess debris, earth, and impurities. This may involve sawing, cutting, and splitting the blocks into smaller sizes for further processing.

6. Secondary Processing: Once the stone blocks are cleaned and sorted, they undergo secondary processing to achieve the desired shape, size, and finish. This may include cutting, sawing, grinding, polishing, and shaping the stone using specialized machinery and techniques.

7. Quality Control: Throughout the extraction and processing stages, quality control measures are implemented to ensure that the finished stone products meet industry standards and customer specifications. This may involve visual inspection, dimensional measurement, and testing for strength, durability, and color consistency.

8. Packaging and Distribution: After processing, the finished stone products are packaged and prepared for distribution to customers. This may involve wrapping, crating, or palletizing the products for transportation to wholesalers, distributors, retailers, or end-users.

9. Reclamation and Rehabilitation: Upon completion of stone extraction at a quarry site, reclamation and rehabilitation efforts are undertaken to restore the site to its natural state or to repurpose it for other land uses. This may involve landscaping, revegetation, and environmental restoration to mitigate the impact of quarrying activities.

Overall, the extraction of natural stone involves a complex process that requires careful planning, coordination, and adherence to environmental and safety regulations to ensure sustainable resource utilization and minimize negative impacts on the environment.

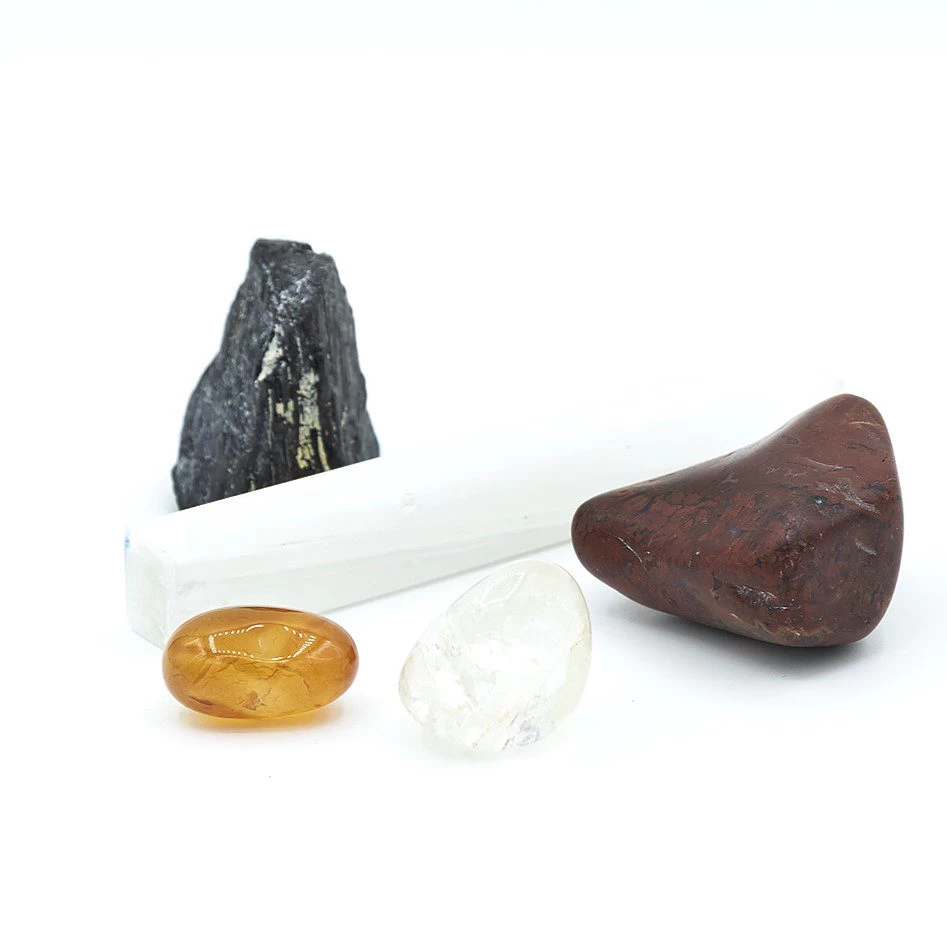

Stone processing refers to the various methods and techniques used to transform natural stone from its raw form into finished products suitable for use in construction, landscaping, interior design, and other applications. Stone processing involves several stages, including quarrying, cutting, shaping, finishing, and installation. Here's an overview of the stone processing steps:

1. Quarrying: The process of extracting stone blocks or slabs from natural stone deposits, typically conducted in quarries using techniques such as drilling, blasting, and cutting.

2. Cutting: Once extracted from the quarry, the stone blocks or slabs are cut into smaller, more manageable sizes using specialized machinery such as diamond wire saws, gang saws, or bridge saws.

3. Shaping: After cutting, the stone pieces may undergo further shaping to achieve specific dimensions or designs. This can involve techniques such as milling, profiling, grinding, or carving.

4. Finishing: The surface of the stone is treated to achieve the desired texture, appearance, and durability. Common finishing techniques include polishing, honing, brushing, flaming, sandblasting, or bush hammering.

5. Quality Control: Throughout the processing stages, quality control measures are implemented to ensure that the finished stone products meet the required standards in terms of size, shape, color, texture, and structural integrity.

6. Packaging and Transport: Once processed, the finished stone products are carefully packaged and prepared for transportation to their final destination, whether it's a construction site, a showroom, or a customer's location.

7. Installation: Finally, the finished stone products are installed according to the specific requirements of the project, whether it's flooring, cladding, countertops, monuments, sculptures, or other applications.

Overall, stone processing involves a combination of mechanical, chemical, and manual techniques to transform raw stone into a wide range of functional and decorative products.

1. Extraction: Natural stone is typically quarried from mines or open-pit mines where large blocks of stone are extracted from the earth's crust. This process involves drilling, blasting, cutting, and transporting the stone blocks to processing facilities.

2. Processing: Once extracted, the stone blocks undergo various processing steps to create finished products. This may include cutting, sawing, polishing, grinding, and shaping the stone to meet specific size, shape, and finish requirements.

3. Manufacturing: Processed stone is used to manufacture a wide range of products such as slabs, tiles, countertops, flooring, cladding, pavers, monuments, and sculptures. These products are produced in factories or workshops using advanced machinery and techniques.

4. Distribution: Finished stone products are distributed to various markets and industries through wholesalers, distributors, retailers, and exporters. The distribution network may involve local, national, or international trade depending on the demand and market conditions.

5. Applications: Natural stone is used in a diverse range of applications across different sectors. In the construction industry, it is commonly used for building facades, flooring, countertops, walls, and decorative elements. In the architectural and interior design fields, natural stone adds elegance and sophistication to residential, commercial, and public spaces. Stone is also used in landscaping projects, urban design, monuments, memorials, and art sculptures.

5. Applications: Natural stone is used in a diverse range of applications across different sectors. In the construction industry, it is commonly used for building facades, flooring, countertops, walls, and decorative elements. In the architectural and interior design fields, natural stone adds elegance and sophistication to residential, commercial, and public spaces. Stone is also used in landscaping projects, urban design, monuments, memorials, and art sculptures.6. Sustainability: The stone industry is increasingly focused on sustainable practices to minimize environmental impact and promote responsible sourcing. This includes initiatives to reduce waste, optimize resource use, implement eco-friendly production processes, and support ethical labor practices.

7. Innovation: Advances in technology and manufacturing techniques have led to innovations in the stone industry, allowing for greater customization, precision, and efficiency in product design and fabrication. Digital fabrication technologies, such as CNC machines and waterjet cutting, have revolutionized the way natural stone is processed and shaped.

Overall, the stone industry plays a vital role in the global economy and in shaping the built environment. Natural stone products are valued for their durability, beauty, and timeless appeal, making them a preferred choice for various architectural and design projects around the world.

_1710355199.jpg)

The extraction of natural stone involves several steps, from locating suitable deposits to processing the extracted stone into usable products. Here's an overview of the extraction process:

2. Permitting and Land Acquisition: Once a suitable site is identified, the necessary permits and licenses must be obtained from local authorities and regulatory agencies. This may involve environmental impact assessments, land use planning, and compliance with zoning regulations.

3. Drilling and Blasting: The extraction process typically starts with drilling holes into the earth's surface using specialized equipment. Explosive charges are then inserted into the drill holes and detonated to break apart the rock mass into manageable-sized blocks.

4. Excavation and Transportation: After blasting, excavators and front-end loaders are used to remove the broken rock and transport it to a processing facility or temporary stockpile. Large blocks of stone are often transported using heavy machinery or trucks equipped with cranes.

5. Primary Processing: At the processing facility, the extracted stone blocks undergo primary processing to remove excess debris, earth, and impurities. This may involve sawing, cutting, and splitting the blocks into smaller sizes for further processing.

6. Secondary Processing: Once the stone blocks are cleaned and sorted, they undergo secondary processing to achieve the desired shape, size, and finish. This may include cutting, sawing, grinding, polishing, and shaping the stone using specialized machinery and techniques.

7. Quality Control: Throughout the extraction and processing stages, quality control measures are implemented to ensure that the finished stone products meet industry standards and customer specifications. This may involve visual inspection, dimensional measurement, and testing for strength, durability, and color consistency.

8. Packaging and Distribution: After processing, the finished stone products are packaged and prepared for distribution to customers. This may involve wrapping, crating, or palletizing the products for transportation to wholesalers, distributors, retailers, or end-users.

9. Reclamation and Rehabilitation: Upon completion of stone extraction at a quarry site, reclamation and rehabilitation efforts are undertaken to restore the site to its natural state or to repurpose it for other land uses. This may involve landscaping, revegetation, and environmental restoration to mitigate the impact of quarrying activities.

Overall, the extraction of natural stone involves a complex process that requires careful planning, coordination, and adherence to environmental and safety regulations to ensure sustainable resource utilization and minimize negative impacts on the environment.

Stone processing refers to the various methods and techniques used to transform natural stone from its raw form into finished products suitable for use in construction, landscaping, interior design, and other applications. Stone processing involves several stages, including quarrying, cutting, shaping, finishing, and installation. Here's an overview of the stone processing steps:

3. Shaping: After cutting, the stone pieces may undergo further shaping to achieve specific dimensions or designs. This can involve techniques such as milling, profiling, grinding, or carving.

4. Finishing: The surface of the stone is treated to achieve the desired texture, appearance, and durability. Common finishing techniques include polishing, honing, brushing, flaming, sandblasting, or bush hammering.

5. Quality Control: Throughout the processing stages, quality control measures are implemented to ensure that the finished stone products meet the required standards in terms of size, shape, color, texture, and structural integrity.

6. Packaging and Transport: Once processed, the finished stone products are carefully packaged and prepared for transportation to their final destination, whether it's a construction site, a showroom, or a customer's location.

7. Installation: Finally, the finished stone products are installed according to the specific requirements of the project, whether it's flooring, cladding, countertops, monuments, sculptures, or other applications.

Overall, stone processing involves a combination of mechanical, chemical, and manual techniques to transform raw stone into a wide range of functional and decorative products.

FAQs

What is stone industry?

The stone industry refers to the sector involved in the extraction, processing, manufacturing, and distribution of natural stone products.

What is the role of the stone industry in the economy?

the stone industry plays a vital role in the global economy and in shaping the built environment

What dose stone extraction involves

the extraction of natural stone involves a complex process that requires careful planning, coordination, and adherence to environmental and safety

What does stone processing include?

stone processing involves a combination of mechanical, chemical, and manual techniques to transform raw stone into a wide range of functional and decorative products.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14