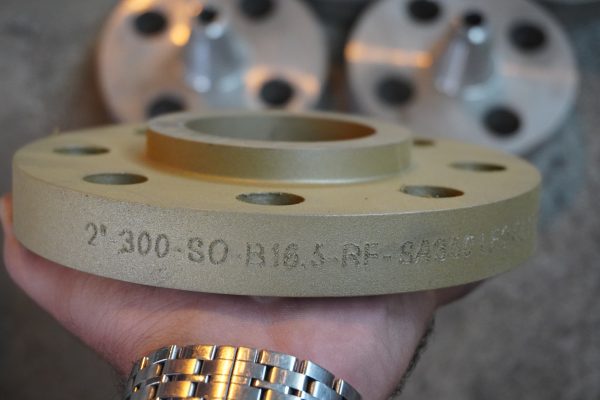

A slip-on flange is a type of flange that is slipped over the end of a pipe and then welded in place. It has a small, straight, and plain hub that extends from the flange face and is used to align the flange to the pipe. Slip-on flanges are popular because they are easy to install and offer convenient access for maintenance or inspection. They are commonly used in low-pressure applications and are available in various sizes and materials to suit different piping systems.

Slip-on flanges have a variety of uses in piping systems. Some common applications of slip-on flanges include:

1. Connecting Pipes: Slip-on flanges are used to connect two pipes together. They are welded to the outside of the pipe, providing a strong and leak-proof joint.

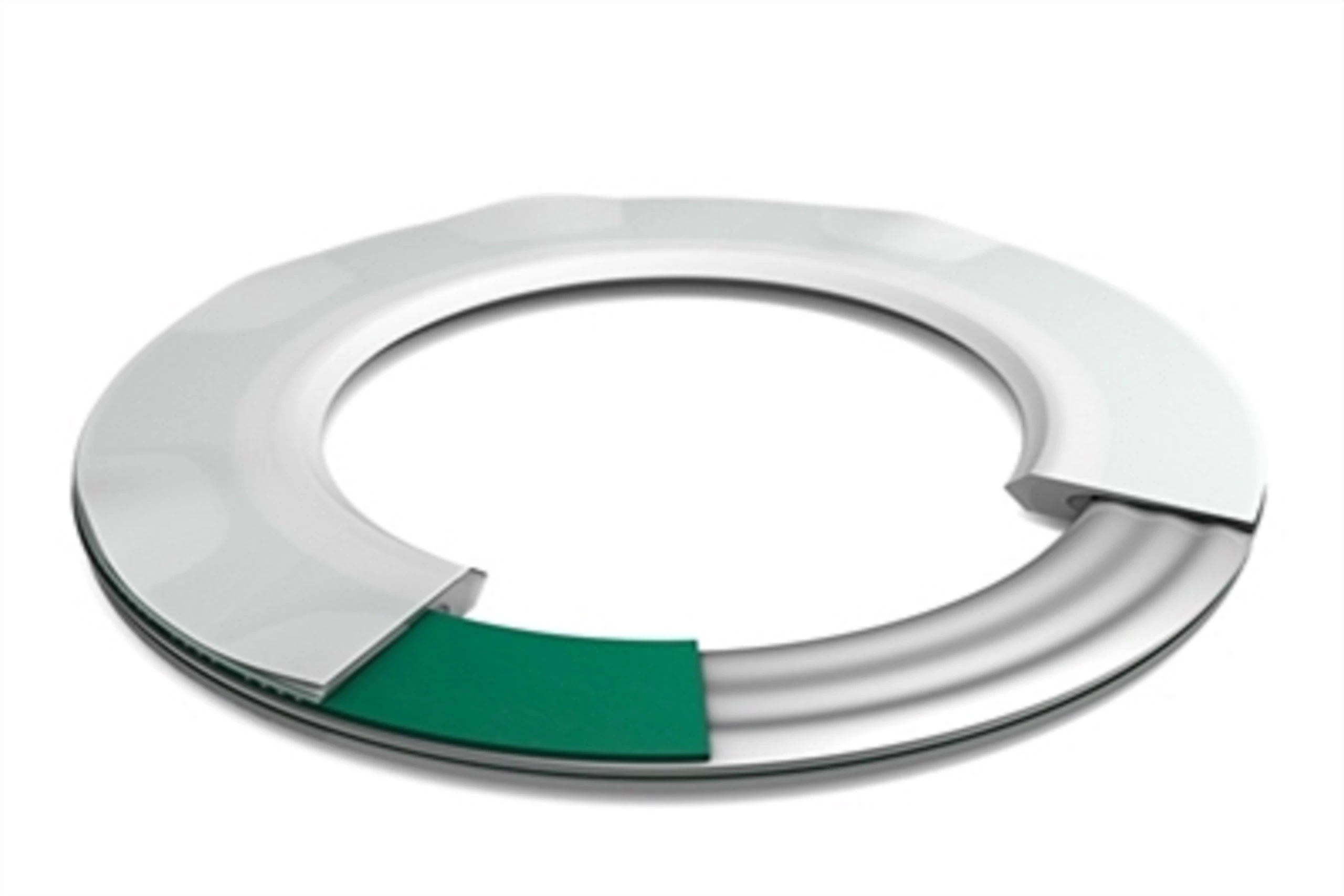

2. Joining Pipes to Fittings: Slip-on flanges can be used to connect pipes to various fittings, such as valves, pumps, or expansion joints. They provide a secure connection and allow for easy installation or removal of the fitting if needed.

3. Access Points: Slip-on flanges are often used as access points in piping systems. They can be welded onto a pipe to create an opening for inspection, cleaning, or maintenance purposes. This allows for easy access to the interior of the system without the need to dismantle the entire pipeline.

4. Flanged Connections: Slip-on flanges are frequently used to create flanged connections. By welding slip-on flanges to both ends of a pipe, a flanged connection is formed. This allows for easy alignment and assembly of pipes with other flanged components, such as flange valves or flange elbows.

5. Low-Pressure Applications: Slip-on flanges are commonly used in low-pressure piping systems and where the pressure requirements are not too high. They are suitable for applications such as water supply, drainage, and general plumbing installations.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves