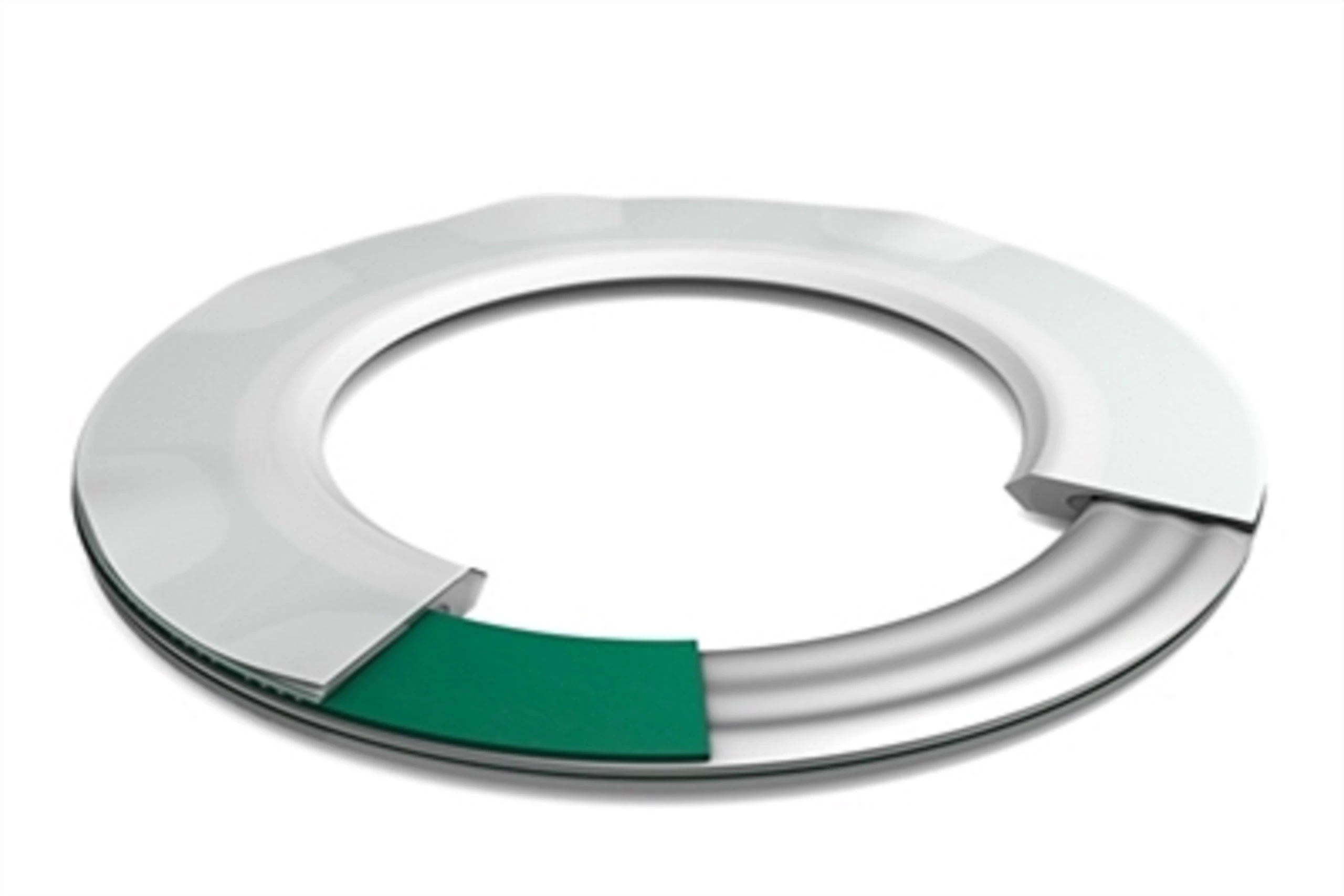

Insulation kits are a type of insulating gaskets that are mainly used to cut off electrical currents in flanges and other connections. Insulation kits are used to electrically isolate the flanges of underground pipes. This electrical insulation is generally used to prevent leakage current to structures that should not be protected. Also, this electrical insulation reduces leakage and stray current in cathodic protection systems.The insulation kit consists of the following three parts:

• Gasket: The gasket is a piece that is placed between two flange surfaces and isolates the underground part of the flange from the above ground part. Usually, its material is Phenolic Resin.

There are three types of gaskets: Type E: Full Face (FF) (the gasket covers the entire surface between the two flanges and the passage of the flange screws is also installed on the gasket) and Type F: Raised Face (RF) (the gasket only has two It includes the inner edge of the flange) and type D, which is placed in the form of a ring inside the housing of ring flanges, and they are made in different pressure classes such as: 150, 300, etc. according to ASME, ANSI standards. The type of gasket, its size and class are selected based on the specifications of the flange.• Sleeve: a polyethylene tube is placed on the flange screws and is used to insulate the screw from the flange body (the said screws may be extruded from mica material).

• Washer: The washers are made of Phenolic Resin and are used to insulate the nut and washer from the flange body. This insulation can be supplied with materials such as oxylas fiber and phenolic, polyethylene and Teflon.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves

.png)

.png)