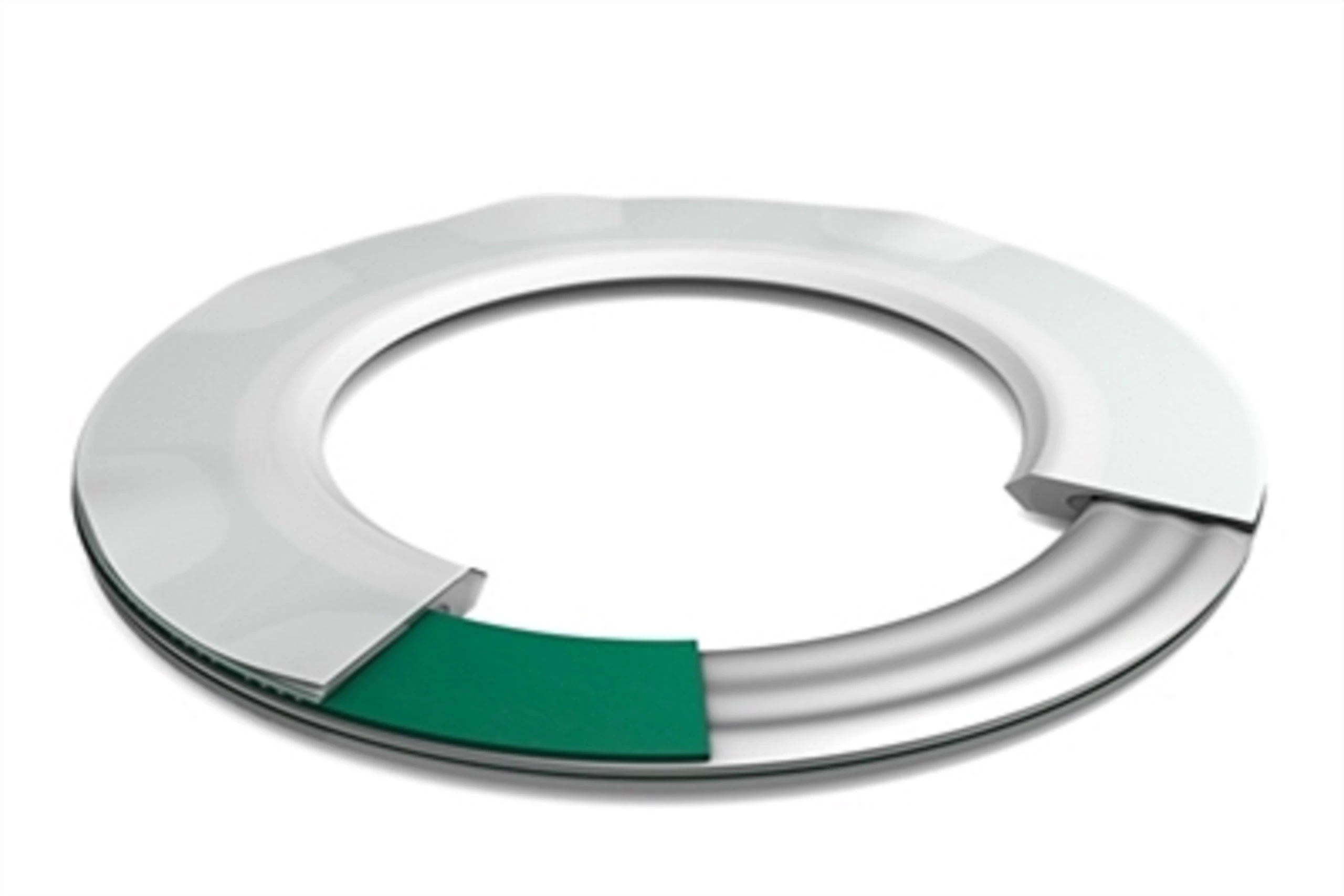

A Class 600 weld neck flange refers to a specific type of flange with a pressure rating of Class 600. Class 600 flanges are designed to withstand higher pressure compared to lower class flanges and are commonly used in applications requiring increased pressure resistance.

Some key features of a Class 600 weld neck flange include:

1. Pressure Rating: The Class 600 designation indicates that the flange is designed to handle a maximum pressure of 600 pounds per square inch (psi) or approximately 41 bar.

2. Weld Neck Design: A weld neck flange has a long, tapered hub with a circular bore that matches the internal diameter of the pipe. The flange is welded to the pipe, providing a strong and rigid connection.

3. Material Compatibility: Class 600 weld neck flanges are available in various materials such as carbon steel, stainless steel, alloy steel, or other exotic materials. The choice of material will depend on the specific requirements of the application, such as corrosion resistance or high-temperature tolerance.

The selection of a flange, including the Class 600 weld neck flange, should consider factors such as the pipe size, material compatibility, temperature, and pressure requirements. It is essential to consult relevant industry standards and guidelines, such as ASME B16.5, to ensure the flange is suitable for the intended application.

Working with a qualified engineer or piping specialist is recommended to ensure the correct selection, installation, and adherence to relevant codes and standards when using a Class 600 weld neck flange.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves