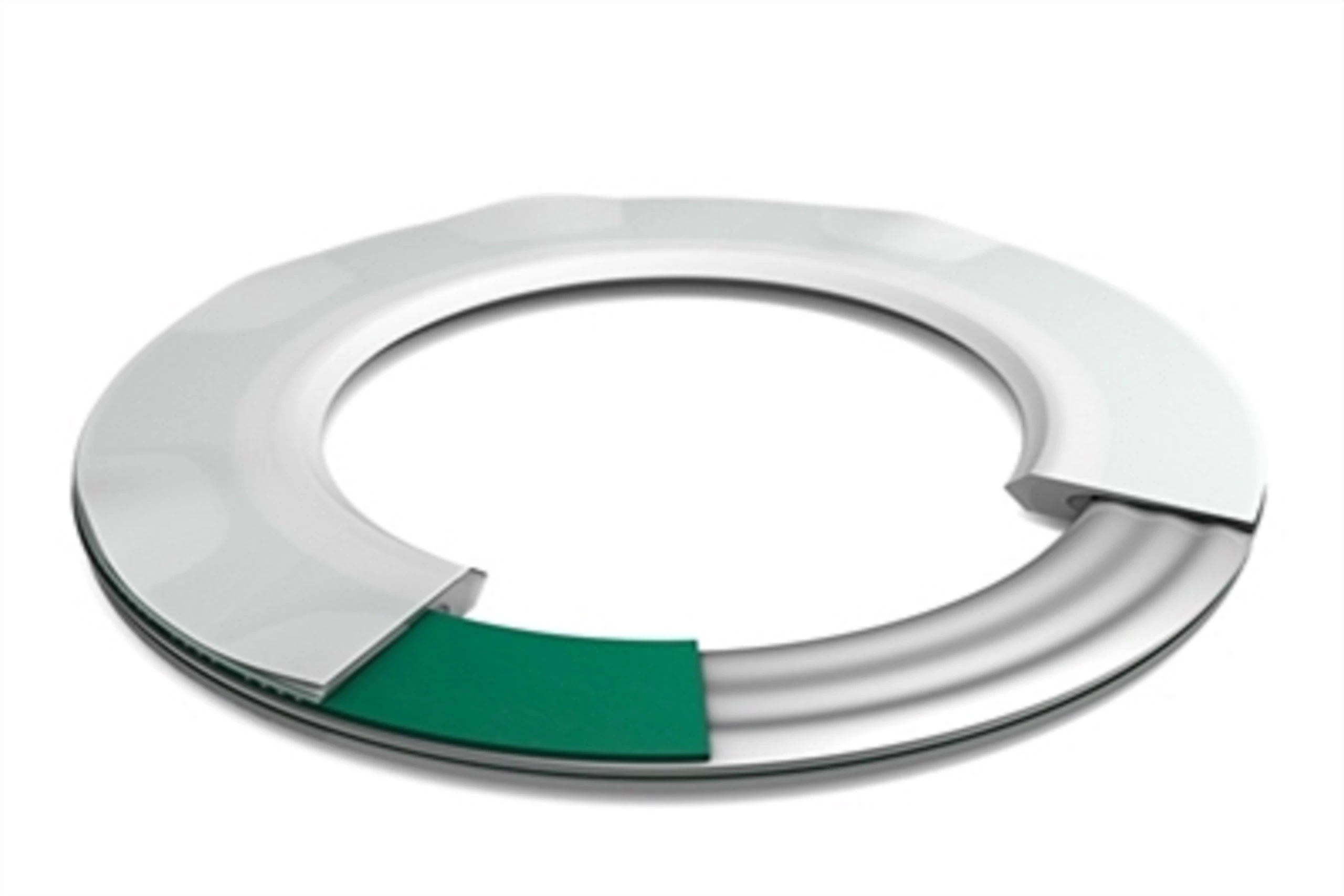

A weld neck flange with a 28-inch nominal size refers to a flange that is designed to be welded to a pipe with a 28-inch internal diameter. Weld neck flanges are commonly used in piping systems to provide a secure and leak-tight connection.

The key features of a weld neck flange include:

1. Hub and Bore: A weld neck flange has a protruding hub with a circular bore that matches the internal diameter of the pipe. The hub provides reinforcement and helps to ensure a smooth flow of fluid through the connection.

2. Welding Surface: The outer surface of the flange, known as the welding surface, is designed to be welded to the pipe. The welding process creates a strong and durable connection.

3. Tapered Neck: The neck of a weld neck flange is tapered, allowing for smooth and gradual transition from the flange to the pipe. This helps to reduce stress concentrations and promotes better flow characteristics.

When specifying a weld neck flange, it’s important to consider other factors such as the pressure rating (Class), material compatibility, and any specific industry standards or regulations that apply to your application. Weld neck flanges are available in various sizes and pressure ratings to suit different piping requirements.

If you’re working on a specific project or need further guidance, it is recommended to consult with a qualified engineer or refer to relevant standards such as ASME B16.5 or API 6A to ensure the correct selection and application of the 28-inch weld neck flange.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves