Double jacket gaskets are used in the construction of all kinds of flanges due to the strength of metallic materials and the compressibility of non-metallic fillers as well as acceptable flexibility. It is done by the professionals of this company. Metal jacket gaskets are generally a cost-effective sealing equipment where the sealing surfaces are narrow and the temperature is more than 550 degrees Celsius and can be produced in various forms.

Among the types of these gaskets, the following can be mentioned:

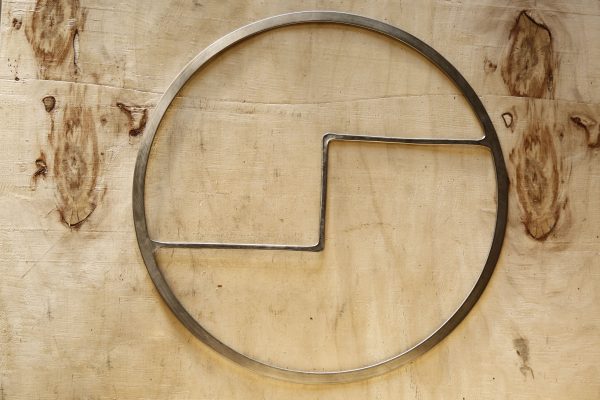

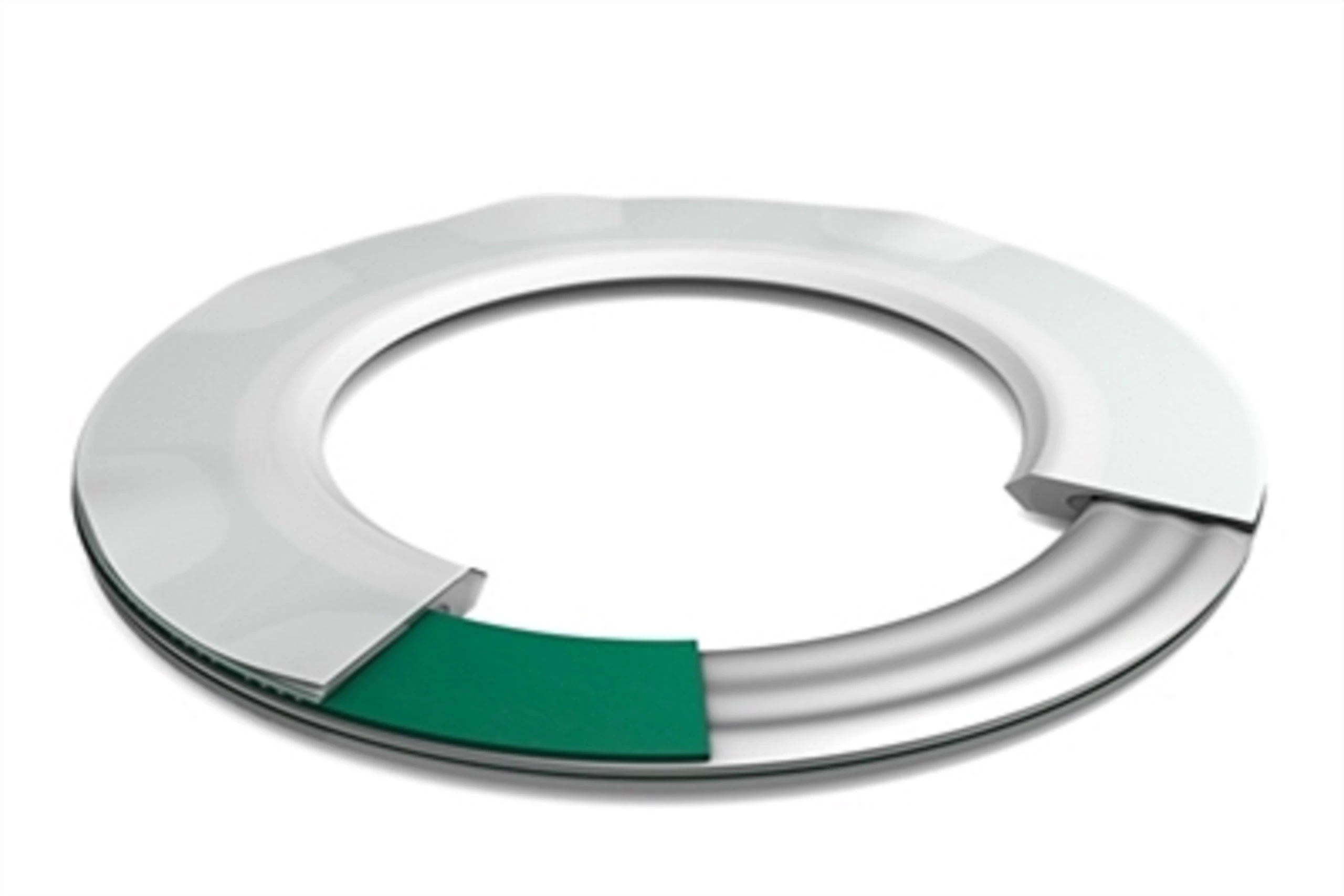

Double Jacketed Gasket

Single Jacketed Gasket

Double Jacketed Corrugated (Soft Filler)

Single Jacketed Gasket Open on Outer Diameter

Single Jacketed Gaskets Totally Enclosed

Corrugated with Cord Rope Facing Corrugated metal core with a nonabestos rope facing

Double Jacketed with Corrugated Metal Filler

Corrugated with Soft Facing Layer

The structure of these gaskets consists of two middle parts of non-metallic shell (Filler) and cover part or metal shell (Jacket Metal), which fillers cause flexibility and the metal cover makes the gasket resistant to pressure, temperature and corrosion. It will depend on the type of flange as well as the fluid.

The materials used in the production of fillers mainly include soft and compressible fillers such as flexible graphite, PTFE or non-asbestos, compressed sheet and mica. Also, in the Jacket Metal section, metals such as soft iron (Aleppo), types of steel (304, 321, 347 and 316), brass and copper (COPPER) are used. The most important application of this type of washers is in heat exchangers, valve caps and special flanges.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves