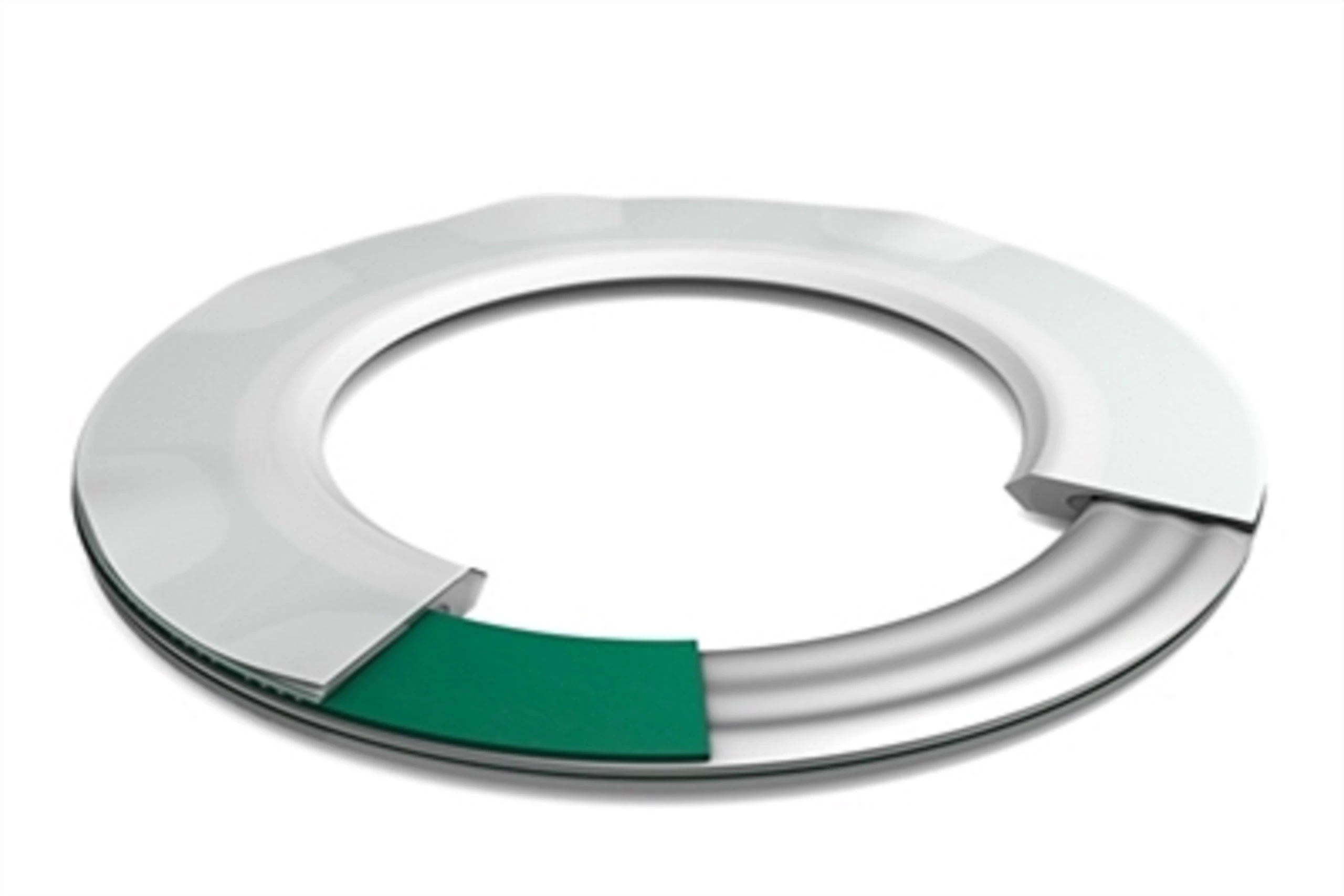

Camprofil washers or grooved washers are suitable for the most demanding applications such as steam, high pressure hydrocarbon and chemical services. These gaskets can be used in conventional power plants, nuclear power plants, chemical and petrochemical industries.

Camoprofile gaskets are made of a single metal core made of common gasket materials such as: carbon steel, stainless steel 304 or 316, and if higher temperatures are required, materials such as Hastelloy and Inconel with machined and concentric grooves on both sides of the accompanying gasket It is made with soft filling material (water seal).Depending on the service, sealing layers or soft filling materials can be made of graphite, Teflon (PTFE) or asbestos. After installing the cam profile gasket, the soft non-metallic filler is pressed into the serrated grooves of the metal core. Comprofil gaskets can be used without sealing layers to provide excellent sealing but there is a risk of damaging the flange surface. Depending on the material of the sealing layer, Camprofil gaskets are resistant to a temperature of 1000 ℃ and a pressure of 250 bar.These gaskets have ASME standard flanges, as well as non-standard flanges including lightweight flanges, valves, pumps, heat exchangers and tanks. Camprofil gaskets are also an excellent choice for worn heat exchangers that were originally designed for coated gaskets.

Features of Camoprofile washer:

Excellent resistance, excellent stability and good ability against leakage

Ease of installation and the ability to rebuild and reuse

Suitable for high pressure and temperature applications and the ability to deal with temperature and pressure fluctuations

Suitable for a wide range of chemicals

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial Valves

Industrial Valves