This machine is used in all packaging lines such as food, dairy, pharmaceutical, health, household appliances and spare parts, tile, ceramic and construction industries, etc. and in simple tunnel, semi-automatic, simple shooter, automatic shrink models. (with shooter and roll opener) and fully automatic (automation, shooter, roll opener, input tape) are produced.

Equipped with industrial automation and PLC

Ability to connect to production lines and adapt to the production process

Easy to use without the need for specialized personnel

Equipped with a special operator's turntable

Equipped with an automatic carton advance system (shooter)

Equipped with an automatic roll unwinding system

Equipped with a sewing and tunnel temperature control system

With a shrink product cooling system

Equipped with a single-phase and three-phase life protection system

With a bar stitching system with industrial fireproof Teflon coating

Equipped with anti-impact electrostatic paint

Strong and reliable stitching using a bar stitching system and auxiliary stitching

Equipped with a tunnel conveyor made of galvanized wire and with a thickness of two millimeters with adjustable speed

Equipped with an element chamber cooling system to increase the efficiency and life of the element

With a spiral air circulation system, the tunnel is equipped with a double-walled tunnel with proper thermal insulation with a diameter of 10 cm

Practical and sturdy design using a 2 mm thick iron chassis

Equipped with an advanced automation system using quality and branded parts (Siemens and Delta)

With 4 swivel wheels for ease of movement

With a monitoring unit and an inlet air pressure adjustment system

Ability to sew nylon up to 1 meter long (the machine can be customized in longer lengths)

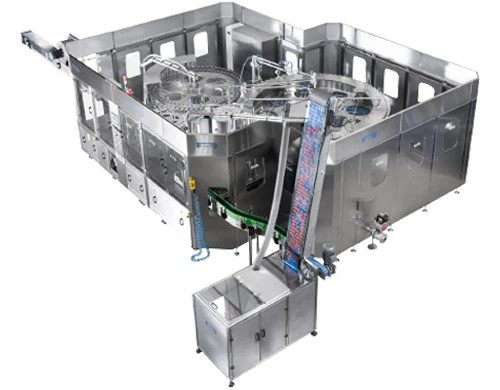

The shrink pack machine is one of the most important packaging machines in a production unit, which first stretches and sews the nylon around the product through a process, and then, with the help of heat and according to the properties of the nylon used, the shrinking operation is performed and the nylon is collected and absorbed around the product.

This machine is used for use in all packaging lines such as the food, dairy, pharmaceutical, health, household appliances and spare parts industries, tiles, ceramics and construction, etc. and is produced in simple, semi-automatic, simple shooter, automatic (shooter and roll opener) and fully automatic (automation, shooter, roll opener, input tape) shrink tunnel models.

The semi-automatic tunnel shrink machine is equipped with a product advance system (shooter) and automatic nylon sewing (roll opener) and in this model, the product is placed manually by the operator at the entrance of the machine and the shrink operation of the machine is started using an industrial pedal or the start key.

The shooter part guides the carton or product to the back of the sewing system, and then the roll is automatically opened, and finally the sewing operation is performed. The product is transferred into the heat tunnel through the tunnel conveyor, and using heat and hot air circulation, nylon is stretched around the product as a protective layer, and finally the product is shrunk after passing through the cooling section and placed on the output table of the machine.

Advantages

Equipped with industrial automation and PLC

Capable of connecting to production lines and adapting to the production process

Easy to use without the need for specialized personnel

Equipped with a special operator's turntable

Equipped with an automatic carton advance system (shooter)

Equipped with an automatic roll unwinding system

Equipped with a sewing and tunnel temperature control system

Equipped with a shrink product cooling system

Equipped with a single-phase and three-phase life protection system

Equipped with a bar sewing system with industrial fireproof Teflon coating

Equipped with anti-impact electrostatic paint

Strong and reliable stitching using a barbed stitching system and auxiliary stitching

Equipped with a tunnel conveyor belt made of galvanized wire and with a thickness of two millimeters with adjustable speed

Equipped with an element chamber cooling system to increase the efficiency and life of the element

With a spiral air circulation system, the tunnel is equipped with a double-walled tunnel with proper thermal insulation with a diameter of 10 cm

Practical and sturdy design using a 2 mm thick iron chassis

Equipped with an advanced automation system using quality and branded parts (Siemens and Delta)

With 4 swivel wheels for easy movement

With a monitoring unit and an inlet air pressure adjustment system

Ability to sew nylon up to 1 meter long (the machine can be customized in longer lengths)

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines