Extra Information

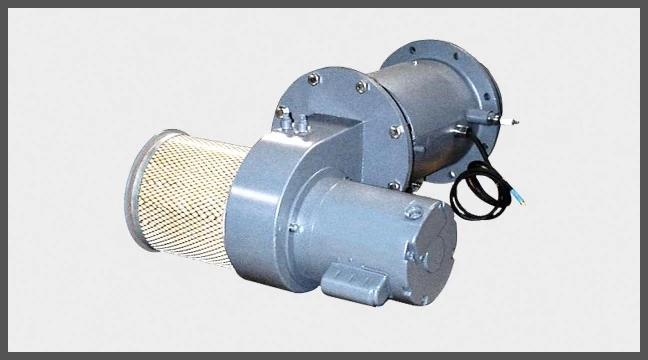

Internal parts of VFG burner consists of a front refractory ring, a steel alloy as flame stabilizer, and a stainless steel nozzle. This burner use gas pressure to create a flame shape and heat pattern that is most advantageous for the installation they are firing. A controlled flame shape is desirable in almost any application that is essential in many to realize optimum furnace performance.

VFG burners are used with ambient temperature combustion air on a wide variety of furnaces operating up to 1100 oC. User can manually select optimum flame shape with the flame adjustment,which is an integral part of the gas/oil connection.

By customers request this model can also be desigend in dual fuel.

FuelGas / Light Oil

P.O.C. VelocityMedium Velocity

Turn-down Ratio6:1 for Gas and 3:1 for Oil

Capacity1,000,000 to 10,000,000 kCal/hr

ApplicationsHeat Treatment, Preheating, Processing, Steam and Hot Water generation and Other Furnaces up to 1100°C

RemarksThese burners are equipped with high temperature resistance burner's tile.

VFG

1000VFG 1,000,000 kCal/hr

3000VFG 3,000,000 kCal/hr

6000VFG 6,000,000 kCal/hr

10000VFG 10,000,000 kCal/hr

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment