Extra Information

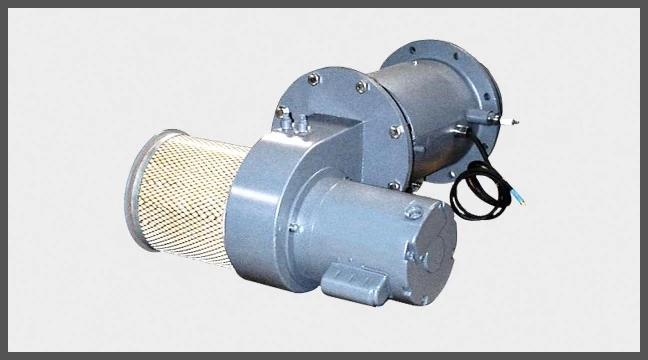

When fuel was cheap, excess air was used to aid temperature uniformity within a furnace load by 1)reducing the hot mix temperature, 2)preventing stratification, and 3)enhancing convection heat transfer. With high velocity burners that induce re-circulation of furnace gases, the recirculating gases produce the above three benefits that formerly required excess air and therefore wasted fuel. High velocity burners are designed to increase convection heat transfer, regardless of the temperature level or loading in the furnace. This convection heat transfer may incidentally heat the refractory walls as well as the load, resulting in considerable radiation heating. The exit velocity of combustion products from burner head is in range of 70 to 230 meters per second velocity. High velocity burners typically have lower NOx emissions than other flame types because of their ability to pull furnace gases into the flame. High flame stability makes these burners great for being used in a wide range of excess air from very low to extremely high.

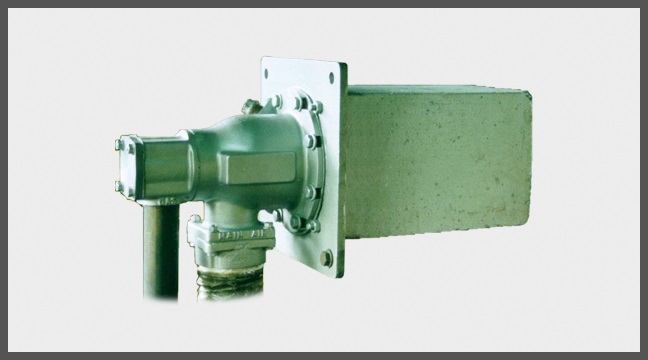

You can order SSECO’s high velocity burners with metal or refractory heads.

FuelGas / Oil

P.O.C. VelocityHigh Velocity

Turn-down Ratio10:1 for Gas and for Oil 6:1

Capacity65,000 to 1,100,000 kCal/hr

ApplicationsHeat Treatment, Melting, Preheating, Other Furnaces up to 1400°C

RemarksThese burners can be ordered with metal or Refractory heads.

NAHG

65NAHG 65,000 kCal/hr

100NAHG 100,000 kCal/hr

150NAHG 150,000 kCal/hr

250NAHG 250,000 kCal/hr

390NAHG 390,000 kCal/hr

680NAHG 680,000 kCal/hr

840NAHG 840,000 kCal/hr

1100NAHG 1,100,000 kCal/hr

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment