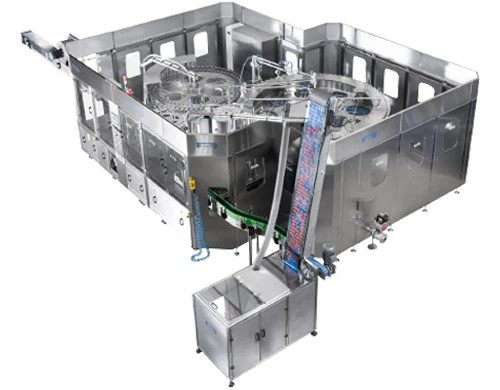

Device specifications:

Packaging items: liquids such as pasteurized milk, buttermilk, school milk, cocoa milk, edible oil, drinking water

Packaging capacity: 4,000 one-liter packages per hour

Packable volumes: 200 ml to 1 liter

Sewing jaws system: pneumatic

Machine control system: by PLC

Ability to connect to CIP washing unit

Stainless steel chassis, switchboard cabinet and liquid passageway

Technical Specifications:

Device dimensions: 170 x 100 x 285 cm (length x width x height)

Machine weight: about 700 kg

Power consumption of the device: 4 kilowatts per hour

Compressed air consumption: 300 liters per minute (6 bar pressure)

Cooling water consumption of sewing jaws: 200 liters per hour (15-20 degrees)

Specifications of the consumable roll:

Three layers of polyethylene and one layer of LDPE

The thickness of the used roll: 90-110 micrometers

The width of the used roll: 33 cm

The diameter of the used roll: maximum 30 cm

Weight of one liter bag: 7 grams

Equipment:

Disinfection of polyethylene rolls by UV rays

Electronic eye to adjust the logo

The date of the thermal woman to insert the date of production and expiration

Balance tank for liquid injection

Warning system for finishing the polyethylene roll and stopping the operation of the machine

The warning system for the end of the thermal history ribbon and stopping the device from continuing to work

Primary pre-heating unit for sewing jaws to remove the primary waste of polyethylene rolls

Changing the parameters of the device through the touch screen.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines