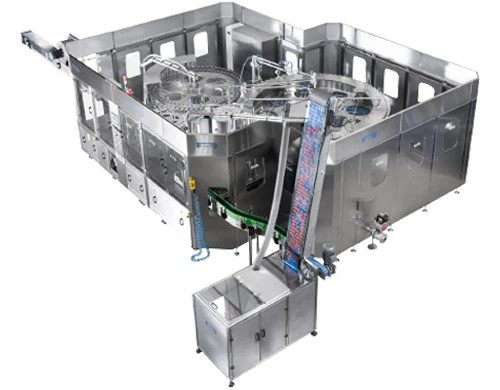

Device length: 4 meters

Device width: 1 meter

Device height: 1.7 meters

Power consumption: 4.5 kW

Packing speed: 60 to 90 packages per minute

Machine weight: 600 kg

In many parts of the world, wooden boxes, cane baskets, China pots, and metal cans are still used for packing bread. Today, the food industry uses low-density polyethylene and polypropylene bags for bread packaging.

In 1916, the first hamburger bun as it is exists today was made by Walter Anderson. This short and squat bun is what is now the standard for hamburger buns. Now, a number of variations can include kaiser rolls, pretzel rolls, or onion rolls, which can be made with dried or crispy onions.

Food Packaging Equipment

Check Weigher.

Fillers.

Sealers.

Vacuum Chamber Machines.

Vacuum Packaging Machines.

The Bread Bagging Process

Place the Bread. Put the loaf of bread on the automated bread bagging machine. ...

Bagging. Once the loaf enters the bagging station, a strong gust of air will blow open the available bag. ...

Sealing. After the bagging process, it needs to be sealed to preserve freshness. ...

Slicing. ...

The Heat Sealer Parts.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines