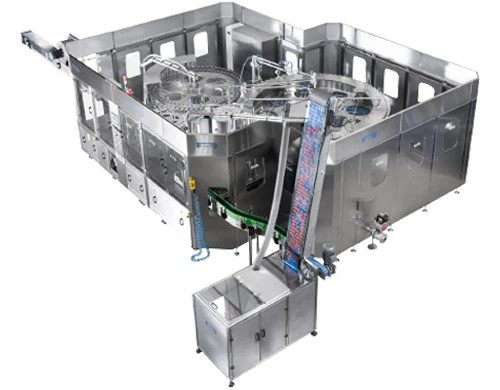

Device specifications:

Packing items:

Liquids such as mayonnaise, ketchup, tomato paste, hotmelt glue

Solid and liquid ingredients such as canned olives, soups, pickles

Solid ingredients in the form of powder, granules, frozen vegetables, IQF, pizza cheese

Package sizes: from 100 grams to 1 kilogram

Packing capacity:

2000 packages per hour for liquids and solids

1200 packages per hour for thick liquids

Sewing jaws system: servo motor, pneumatic

Machine control system: by PLC

Ability to connect to washing unit: CIP

Stainless steel chassis, switchboard cabinet and liquid passageway

Technical Specifications:

Device dimensions: 100 x 100 x 270 cm (length x width x height)

Machine weight: about 500 kg

Power consumption of the device: 4 kilowatts per hour

Compressed air consumption: 300 liters per minute (6 bar pressure)

Cooling water consumption of sewing jaws if packed in polyethylene roll: 100 liters per hour (15-20 degrees)

Specifications of the consumable roll:

Polyethylene and polyester laminate or polyethylene, aluminum and polyester laminate

The thickness of the used roll: 90-110 micrometers

Usable roll width: 30 cm maximum

Weight of one liter bag: 7 grams

Selected items:

Weighing or Auger (spiral) filling system

Packing in three-layer polyethylene and one-layer LDPE roll

Different sizes of packaging with a change of tube and collar

Equipment:

Disinfection of polyethylene rolls by UV rays

Electronic eye to adjust the logo

The date of the thermal woman to insert the date of production and expiration

Volumetric balance tank for filling the solid phase in the form of volumetric cups

Warning system for finishing the polyethylene roll and stopping the operation of the machine

The warning system for the end of the thermal history ribbon and stopping the device from continuing to work

Primary pre-heating unit for sewing jaws to remove the primary waste of polyethylene rolls

Changing the parameters of the device through the touch screen

Step elevator to transfer the solid phase of packaging to the volumetric balance tank

Conveyor to transfer the packages after packaging to the work table surface.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines