– It has a spiral wind deflector system to circulate and even out the air in the tunnel

– The presence of initial heat and later at the beginning and end of the tunnel

– Insulation of three layers of glass wool, stone wool and air in the walls and roof of the tunnel

– Complete piping and channeling of the tunnel for the passage of wires, cables and pneumatic hoses

-Adjustment of hot air dampers inside the tunnel around the product (walls and top)

– Special stainless steel stove with a separate gas burner

-Initial and final conveyors in the form of double-wing chain cans reinforced against impacts caused by forklift loading, each 170 cm long and 120 cm wide.

-Tunnel conveyor in the form of a can and chain with two reinforced wings to support weights up to 2500 kg with a length of 500 cm

– Opening and closing the machine doors pneumatically in order to prevent damage to the machine and the pallet before and after shringing.

Send message to author

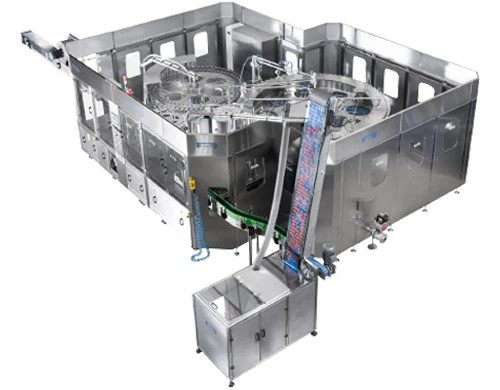

Pallet shearing machine SH-750CG tunnel

2023-09-27 13:40:55

Mobile number:

Email:

Address:

Type of activity:

Phone:

Site:

Comments

Related posters

© 2024 Copyright: mallmir.com

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines