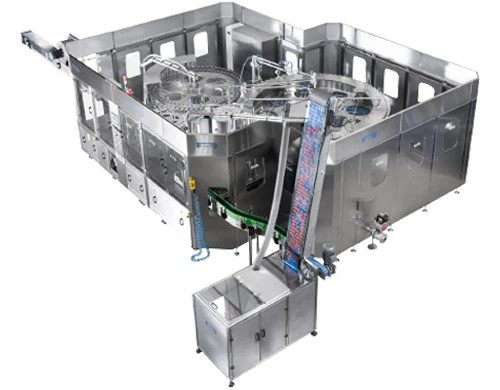

It’s used to sort rice from waste materials and nonwhite rices.

Technical specifications:

Capacity: 1 – 12 tons per hour

Precision: Up to 99%

Able to detect more than one million combination colors

Sorting is the final process of rice milling process(before packing) The electrical machine working by cameras and light removes the unwanted particles like black rice,discoloured rice etc.,Simply speaking all except the white rice are sorted out

A high-resolution CCD optical sensor drives a mechanical sorter to separate different granular materials, automatically sorting heterochromatic particles out of the batch of raw rice; removing such impurities in this process improves the quality of the rice.

For the color sorting process of the rice color sorter, it needs to go through the three processes of whitening, polishing, and grading. At the same time, it must follow the design principles of the rice color sorter, supplemented by a dust collector, and equipped with a compressed air system.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines