Pressure control of oil and gas wells in order to quickly connect and disconnect during measurement is one of the basic and very important principles of safety. The well control panel applies a desired and timely control in terms of correct opening and closing of the well by creating a system called safety shut down system.

When necessary, this system blocks the passage of fluid based on the various warnings it receives. Also, in normal times, this system detects and announces the above actions through the relevant sensors, and then closes the well with safe and correct methods. to be One of these sensors is the fusible plug, which is sensitive to heat and as soon as it senses abnormal heat, it causes the well to be closed by sending signals to the system, and finally, the opening and closing of the well is done by two safety valves.

Temperature and pressure: In these two cases, the minimum and maximum values and the working pressure of the well should be determined.

The degree of protection of different enclosures: in this case IP is related to the desired environmental conditions.

Degree of anti-explosion protection (EX): In this connection, the exact type of protection must be specified according to the existing standards.

Corrosion protection: The type of metallurgical goods must be precisely determined in relation to the preservation of different parts against corrosive factors in the environment.

Send message to author

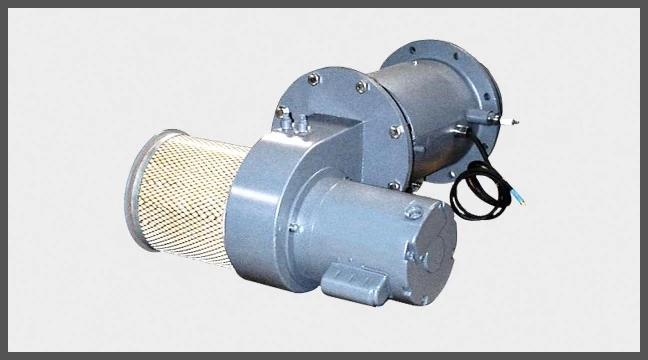

Well head control panel

2023-11-30 15:45:35

Email:

Address:

Type of activity:

Fax:

Site:

Comments

Related posters

© 2024 Copyright: mallmir.com

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment