HSAW Pipe For Water Pipelines

The production of spiral pipes used in water transmission pipelines in the Salvechagan Pipe and Covering Company from 6 to 120 inches is done in a one-step or online process. This method is one of the most common pipe production methods in the world and the first form of spiral pipe production. The production steps in this method are:

a) Sheet preparation

b) Forming the sheet

c) Sub-powder welding inside and outside

In the sheet preparation stage, the ends of the sheets are welded to each other and the edge of the sheet is chamfered and smoothed. If the forming operation is done completely, the edge of the sheet should be pre-bent to prevent the formation of unpressable protrusions. To weld the spiral seam, first the inner seam will be welded at the 6 o'clock position by the sub-powder welding machine. The external pass will also be welded at the 12 o'clock position. The adjustment of the welding nozzle is done automatically. After welding the seam, the pipe will be cut and transferred to the next steps. The production speed in this method is determined based on the speed of sub-powder welding.

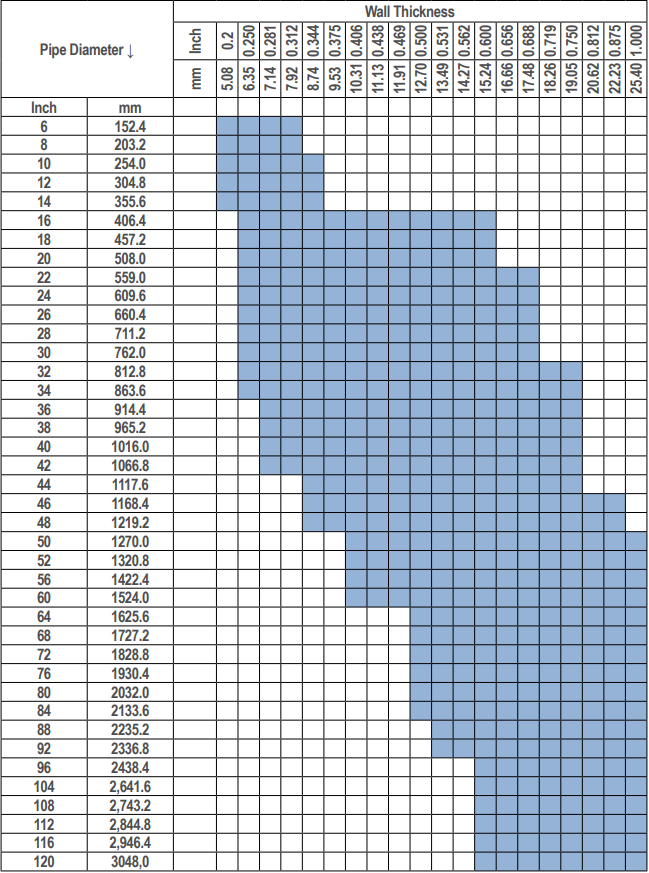

The products of this company are produced in accordance with API, IPS and other national and international standards according to the table below with various thicknesses:

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment